Understanding Centerless Grinding Machine Manufacturers

Centerless grinding is a precise manufacturing process that plays a critical role in producing components with high accuracy and efficiency. The technology is especially significant for industries that require precision ground parts, such as automotive, aerospace, medical, and machining sectors. This article delves into the world of centerless grinding machine manufacturers, highlighting their importance, innovations, and trends in the industry.

Centerless grinding differs from traditional grinding methods by eliminating the need for a spindle. Instead, the workpiece is held in place using a set of wheels the grinding wheel and the regulating wheel. This configuration allows for faster, continuous production of cylindrical parts, making it an efficient choice for high-volume manufacturing. As such, manufacturers of centerless grinding machines are vital to ensuring that companies can achieve the high standards required in precision engineering.

Several key manufacturers dominate the centerless grinding machine market, each offering unique characteristics and innovations. Leading companies, such as Cincinnati, Royal Master Grinders, and Jainnher Machine, have established themselves through years of experience and continued investment in research and development. They provide various models and configurations to meet the diverse needs of customers, from small workshops to large-scale industrial operations.

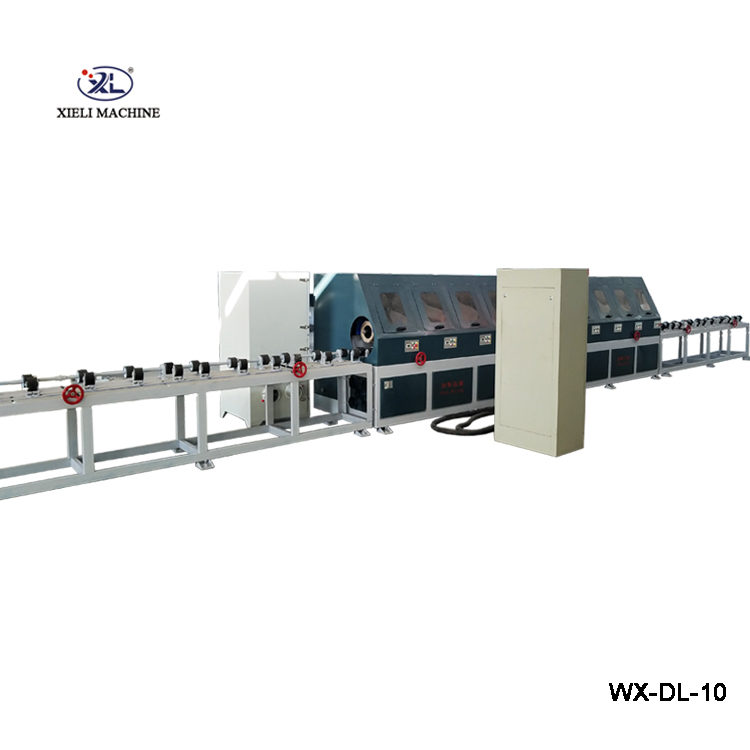

centerless grinding machine manufacturers

One of the primary trends in the industry is the integration of advanced technology into centerless grinding machines. Automation, for instance, is becoming increasingly prevalent, enabling manufacturers to enhance productivity and reduce labor costs. Many companies are now incorporating robotics into their grinding processes, allowing for greater efficiency and precision. This shift not only streamlines production but also minimizes human error, ensuring the final products meet stringent quality standards.

Moreover, there is a growing emphasis on custom solutions. Many centerless grinding machine manufacturers now offer tailored equipment to meet specific customer requirements. By considering factors such as material type, desired tolerances, and production volume, these manufacturers can provide machines designed for particular applications. This customization approach not only enhances customer satisfaction but also helps manufacturers differentiate themselves in a competitive market.

Sustainability is another important factor influencing the centerless grinding industry. As environmental concerns continue to rise, manufacturers are increasingly focusing on eco-friendly practices. This includes the development of machines designed to minimize energy consumption and waste production. For instance, many new models incorporate technologies that allow for recycling used abrasives and optimizing coolant usage, demonstrating the industry's commitment to sustainable manufacturing practices.

In conclusion, centerless grinding machine manufacturers play a pivotal role in the advancement of precision engineering across various industries. Their focus on innovation, automation, customization, and sustainability ensures that they remain at the forefront of manufacturing technology. As the demand for high-performance, precise components continues to grow, these manufacturers will undoubtedly evolve, adapting to the changing landscape while providing essential equipment that drives productivity and quality in the manufacturing process. The future of centerless grinding holds exciting potential, with advancements that promise to further enhance efficiency and effectiveness within the industry.