Centerless Grinding Machines for Sale A Comprehensive Overview for Manufacturers

In the world of precision manufacturing, centerless grinding machines play a crucial role in achieving high tolerances and a superior finish on cylindrical components. These machines eliminate the need for support fixtures, allowing for efficient processing of workpieces that require uniformity and precision. For manufacturers looking to invest in centerless grinding solutions, understanding the key features and the current market landscape is essential.

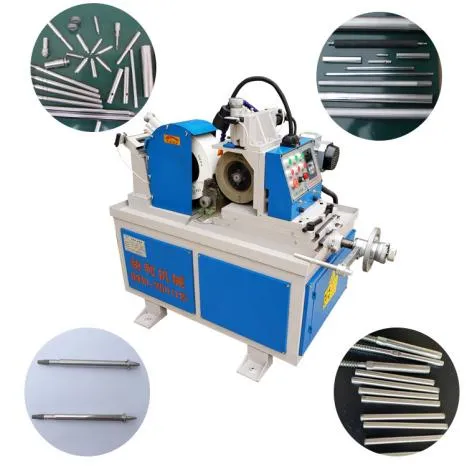

Centerless grinding is a manufacturing process that involves placing a workpiece between two grinding wheels—one fixed and one rotating—for effective material removal. This unique setup enables continuous production of cylindrical parts, making it ideal for high-volume applications. These machines are widely used in industries including automotive, aerospace, and medical manufacturing, where precision and consistency are paramount.

When considering a purchase, manufacturers should look for key features such as grinding capacity, spindle speed, wheel size, and overall machine rigidity. Advanced centerless grinding machines offer various automation options, enhancing not only productivity but also the repeatability of processes. For instance, CNC (Computer Numerical Control) centerless grinders enable manufacturers to program complex grinding cycles, optimizing cutting performance and reducing cycle times.

centerless grinding machine for sale manufacturers

Furthermore, the materials used in the construction of grinding machines significantly influence their durability and performance

. Models constructed from high-quality cast iron provide stability and vibration dampening, which are critical for maintaining accuracy during grinding operations.As of 2023, there exists a diverse market for centerless grinding machines, with numerous manufacturers offering specialized equipment tailored to different applications. Brands renowned for their innovative engineering and reliability often dominate this space, but emerging manufacturers are also gaining traction by offering cost-effective alternatives without compromising quality.

For manufacturers contemplating the acquisition of a centerless grinding machine, it’s advisable to conduct thorough research, including comparisons of different manufacturers, exploring customer reviews, and evaluating after-sales support. Since the right machine can significantly enhance manufacturing efficiency and product quality, investing time in making an informed decision is invaluable.

In conclusion, centerless grinding machines are an integral part of modern manufacturing processes, providing a streamlined method for producing high-precision cylindrical components. By considering the latest advancements, manufacturers can find machines that not only meet their production needs but also contribute to sustaining competitive advantages in a rapidly evolving market.