Centerless grinding machines represent a pinnacle of precision in the manufacturing process, catering to industries that demand high quality, efficiency, and consistently accurate output. For businesses looking to integrate these machines into their operations, understanding their capabilities, applications, and advantages is crucial.

Experience in the field reveals that the uniqueness of centerless grinding lies in its capacity to execute high-volume production runs with impeccable precision.

Unlike traditional grinding methods, centerless grinding does not require fixtures to hold the workpiece. Instead, it relies on the relative positioning of a grinding wheel, a regulating wheel, and the work rest. This mechanism reduces setup time and allows for grinding multiple workpieces at once, significantly increasing efficiency and throughput.

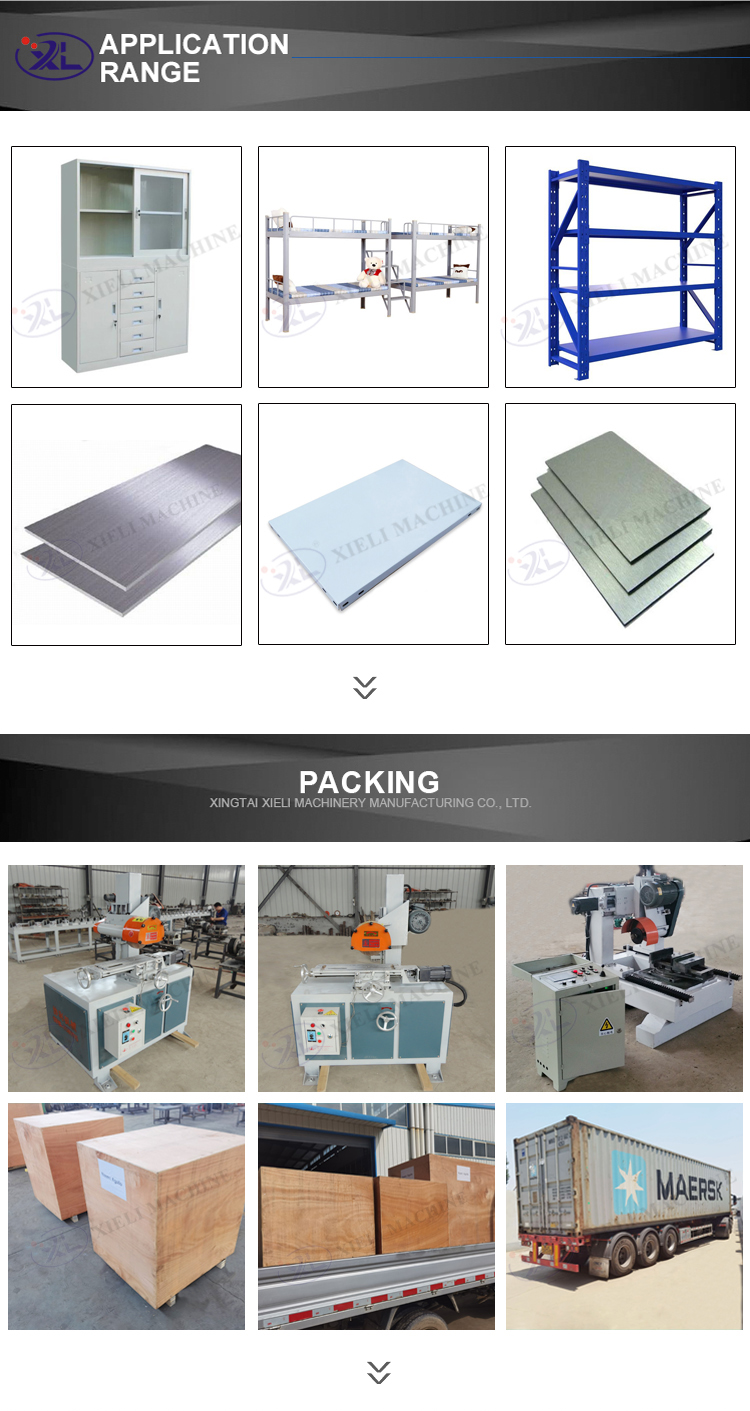

Professionals in manufacturing and machining industries appreciate centerless grinding machines for their unparalleled control over tight tolerances. These machines are particularly suited for crafting cylindrical parts with precise diameters and fine surface finishes. Industries such as automotive, aerospace, and medical device manufacturing depend on centerless grinding technology for components like bushings, pins, and various shafts, where precision is non-negotiable.

The expertise involved in operating a centerless grinding machine centers on understanding the subtleties of machine setup, including the adjustment of the regulating wheel and work rest. Skilled operators ensure that the workpieces maintain the desired specifications throughout the entire process, adjusting parameters as necessary to accommodate different materials and hardness levels. This expertise ensures that every product meets the industry's stringent quality standards without the need for extensive post-processing.

centerless grinding machine

Authoritativeness in this domain often comes from seasoned manufacturers and industry experts who recognize that the true advantage of centerless grinding lies in its versatility and efficiency. It can handle both small and large batches seamlessly, thus making it an essential tool in high-demand situations. Many authoritative figures in the industry advocate for the integration of automated centerless grinding solutions to maximize production efficiency while maintaining superior product quality.

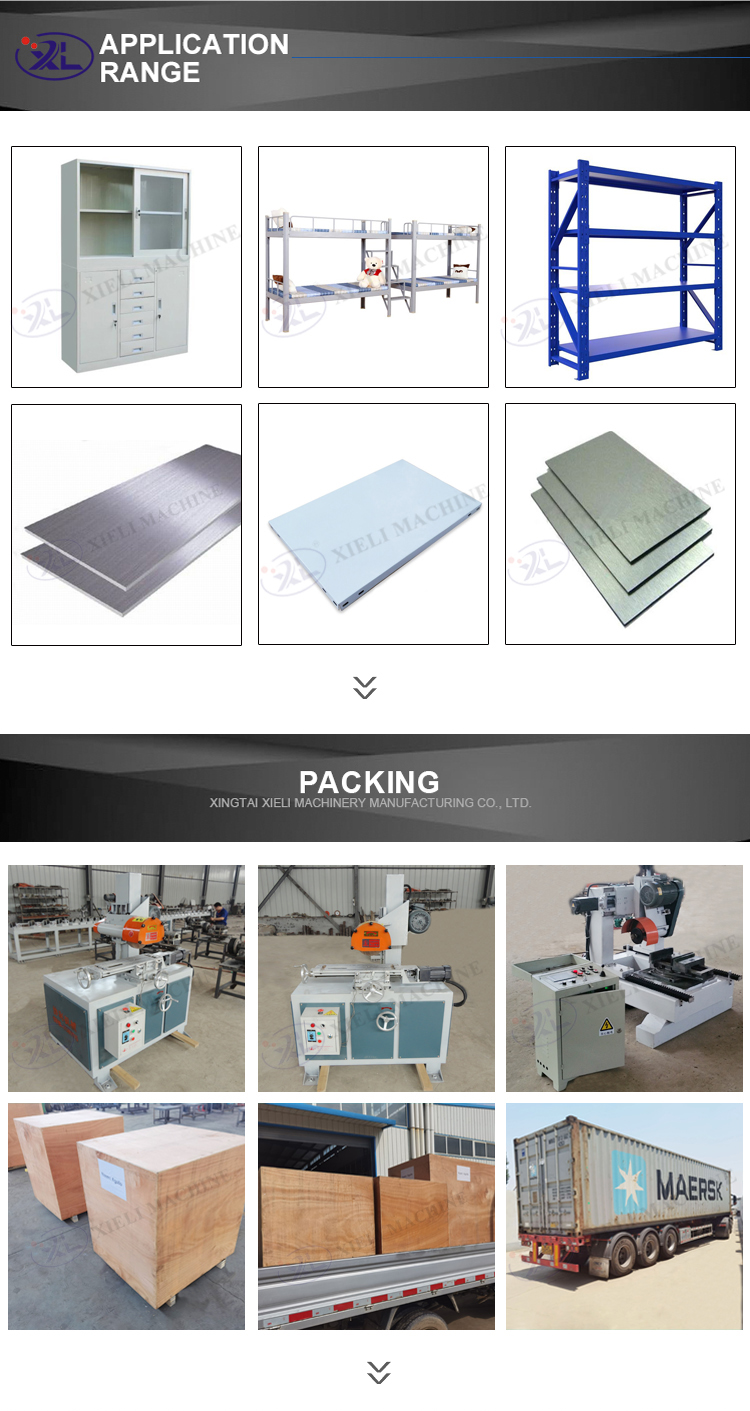

Trustworthiness, or the credibility of a product in the market, is bolstered by the reliable performance of centerless grinding machines. Manufacturers that have invested in top-tier centerless grinding solutions can attest to their durability and consistency over long-term use, contributing to lower operational costs due to decreased downtime and maintenance requirements. Furthermore, by investing in established brands and models known for their precision and longevity, businesses convey a commitment to quality and reliability to their clients and stakeholders.

In summary, centerless grinding machines stand as an influential component in precision manufacturing, enabling enterprises to achieve outstanding quality while optimizing production processes. By leveraging experience, expertise, authoritativeness, and trustworthiness within this field, businesses can propel themselves to the forefront of innovation and efficiency in the manufacturing industry.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.