Centerless Grinding Machines An Overview

Centerless grinding is a manufacturing process that helps achieve high precision and efficiency when shaping materials, particularly metal and plastic parts. Unlike traditional grinding methods, which involve a workpiece being held between centers, centerless grinding allows for continuous operation without the need for external fixtures. This innovative technique has gained popularity in various industries due to its ability to produce components with tight tolerances.

The centerless grinding process involves three main components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the speed and position of the workpiece as it passes through the grinding zone. This unique setup not only aids in achieving a uniform cylindrical shape but also allows for the processing of multiple workpieces simultaneously, significantly increasing productivity.

There are two primary types of centerless grinding through-feed and in-feed. In through-feed grinding, the workpiece is fed continuously through the grinding zone and emerges on the opposite side, making it ideal for cylindrical parts with a constant diameter. On the other hand, in-feed grinding is suited for parts with varied diameters or shapes. This method requires the operator to position the workpiece manually, making it more versatile for complex geometries.

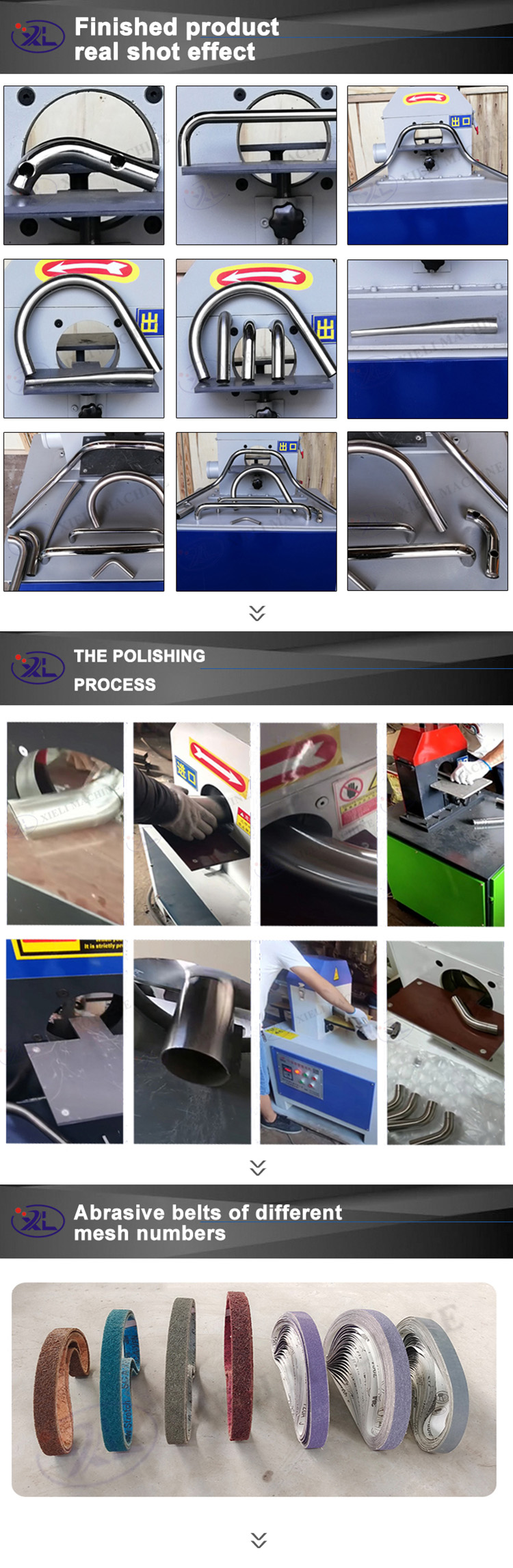

centerless grinding machine

One of the main advantages of centerless grinding is its ability to produce high-quality surface finishes. The grinding process can achieve extremely fine tolerances and a superior surface finish compared to other methods. As the workpieces do not require any fixture sets, this process also reduces production time and setup costs.

Moreover, centerless grinding machines are designed for versatility and efficiency. They can handle a wide range of materials, including hard metals, composites, and plastics. This adaptability makes them essential for industries such as automotive, aerospace, and medical device manufacturing, where precision-engineered components are crucial.

In conclusion, centerless grinding machines are vital tools in modern manufacturing. Their ability to produce high-precision components efficiently makes them indispensable in various industrial applications. With innovations in technology, centerless grinding continues to evolve, offering manufacturers enhanced capabilities and improved productivity. As industries demand increasingly precise parts, the role of centerless grinding machines will likely become even more significant in the future.