Selecting the right grinding equipment is crucial for any machining operation, especially when precision and surface finish are paramount. The combination of a centerless grinder with a surface grinder brings significant advantages to those involved in high-precision component manufacturing. With years of experience in this domain, I've seen firsthand how these tools can elevate both efficiency and production quality.

Centerless grinding is renowned for its ability to produce parts with exceptional precision and surface finishes. Unlike traditional cylindrical grinders, centerless grinders eliminate the need for tooling or fixtures to hold the workpiece. This innovation significantly reduces the time and labor required for setup, allowing for quicker production cycles. The workpiece, supported by a rest blade, is sandwiched between the grinding wheel and a rotary regulating wheel that controls its speed and improvements. Expertise in adjusting the angles and speeds of these wheels results in perfect concentricity and workpiece roundness, making centerless grinding an industry favorite for high-volume precision jobs.

On the other hand, surface grinding addresses the need for refining the surface quality of a workpiece to mirror-like finishes or specifications of tight tolerances. The surface grinder employs an abrasive wheel to remove material incrementally, providing gradual and controlled finishes. With advancements in grinding wheel technology and machine automation, surface grinders have evolved to handle material harder than steel with delicate accuracy. Thus, when paired with a centerless grinder, it completes a cycle of operations that further smoothens and polishes parts to meet stringent client specifications.

Combining a centerless grinder with a surface grinder opens up specialized capabilities that can fulfil diverse and complex industrial needs. For instance, manufacturers in the automotive, aerospace, and tooling industries benefit immensely from such setups. The ability to handle both round and flat surfaces without a changeover period maximizes uptime and productivity. Moreover, integrating these grinders through a continuous feed system enhances throughput, maintaining the swiftness required in competitive markets.

centerless grinder with a surface grinder

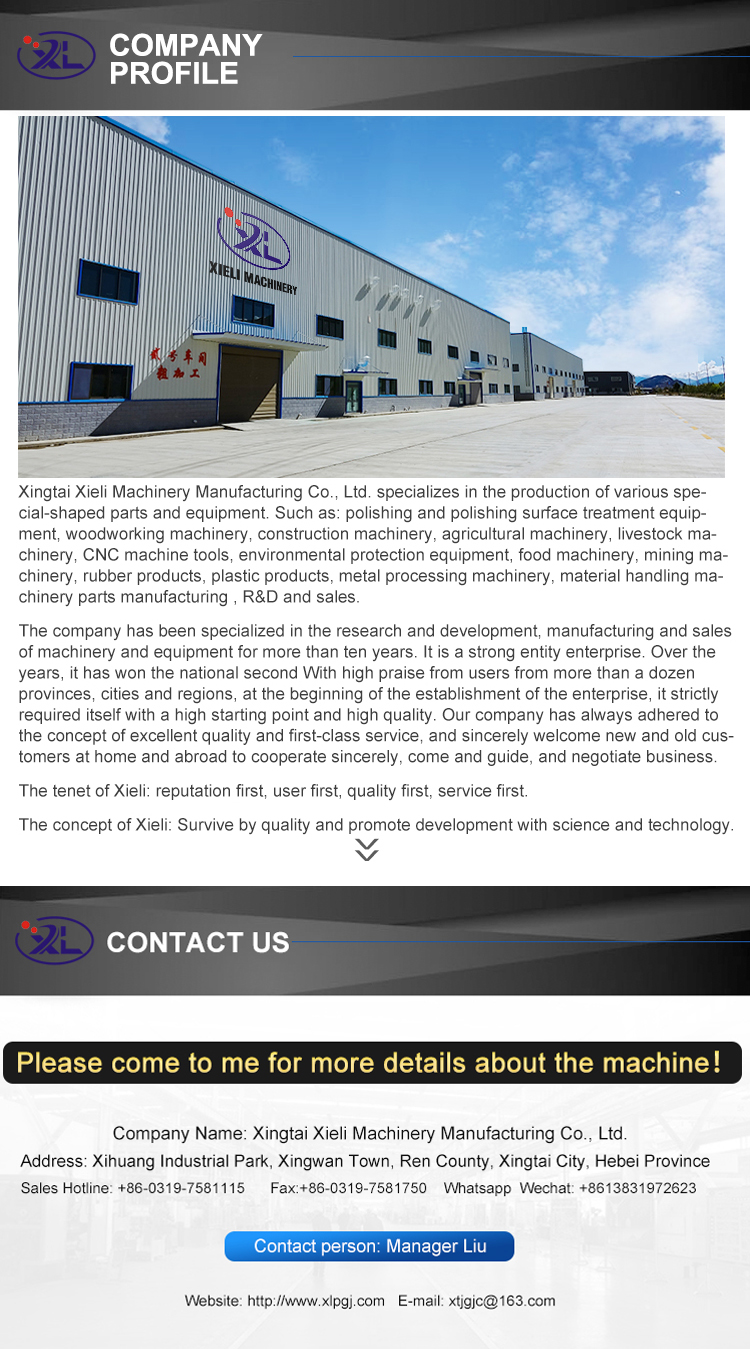

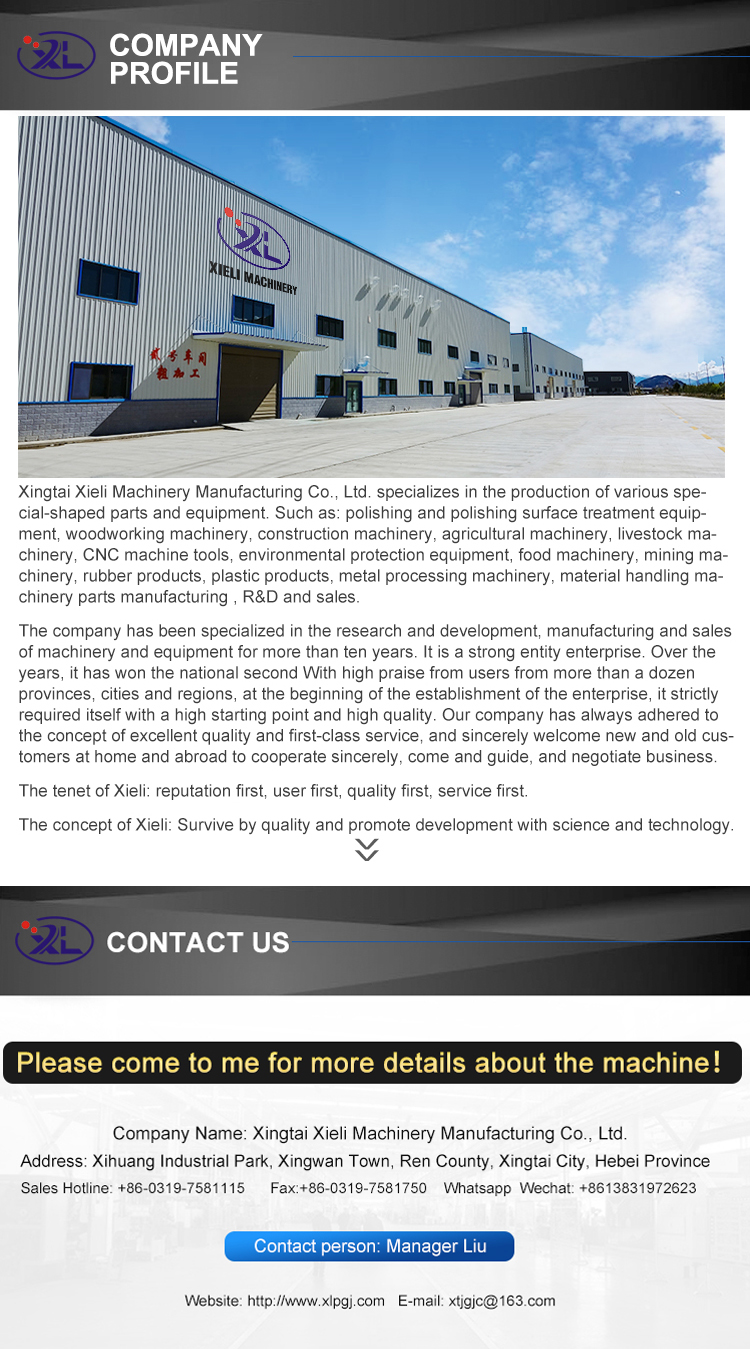

In terms of authoritativeness, many leading companies that pioneer precision machining recognize the benefits of using both centerless and surface grinders. These firms often equip their facilities with top-rated models that demonstrate durability, precision, and consistency. Trusted brands have designed models that incorporate state-of-the-art control systems, programmable features, and eco-friendly options that reduce the environmental impact of grinding activities. Commitment to quality and precision has made these industrial powerhouses influential in shaping standards and practices worldwide.

Trustworthiness in operations requires more than just effective machinery; it demands a skilled workforce adept in delicate machine handling and operation. Continuous training aimed at highlighting the intricacies of grinding machine mechanics and operation serves as an invaluable investment. Employees trained in the symbiotic use of a centerless grinder with a surface grinder not only optimize machinery utility but also ensure adherence to safety standards and reduce the likelihood of malfunctions.

To maintain a competitive edge, regularly upgrading equipment and maintaining a proactive stance towards repair and maintenance is essential. Integrating predictive maintenance strategies can preempt mechanical issues, minimize downtime, and prolong machine life, instilling confidence in clients and stakeholders alike.

In conclusion, the judicious use of centerless and surface grinders in tandem offers remarkable advantages in enhancing production cycles, precision, and component finish quality. Up-to-date technology, trained personnel, and proven grinding techniques play a pivotal role in leveraging these machines' full capabilities, ensuring superior product quality in diverse manufacturing settings.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.