Centerless Grinder Training A Pathway to Precision

Centerless grinding is a critical process in manufacturing, allowing for high-precision production of cylindrical parts without the need for a central axis. As industries evolve, the demand for skilled operators who can effectively use and maintain centerless grinders continues to grow. This is where specialized training programs come into play, ensuring that professionals are well-equipped with the necessary knowledge and skills.

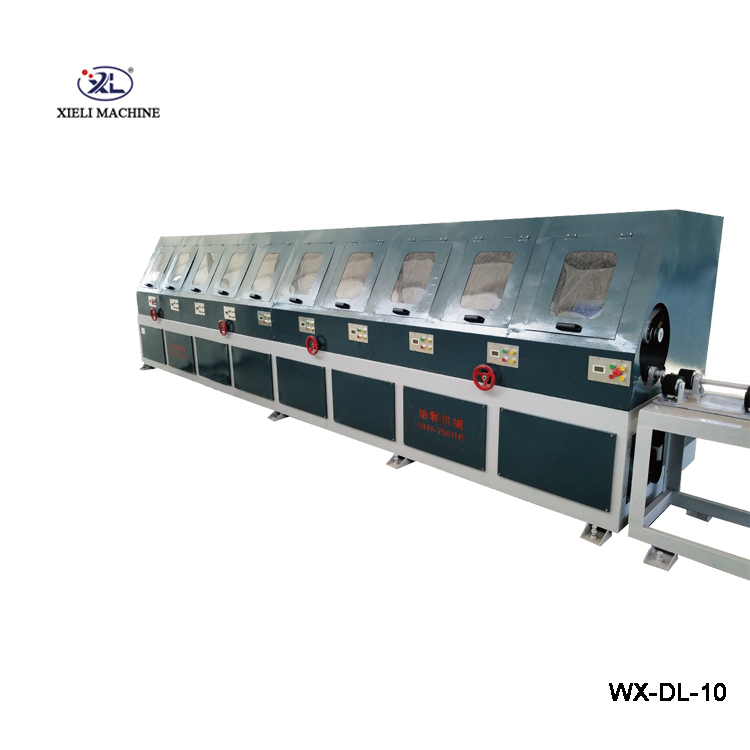

Training centers dedicated to centerless grinder technology provide comprehensive education that covers the fundamentals and advanced techniques of centerless grinding. These programs often begin with an introduction to the machine's components and mechanics, explaining how each part contributes to the grinding process. Participants learn about the differences between in-feed and through-feed grinding methods, an essential distinction for selecting the appropriate technique for different applications.

Practical, hands-on experience is a vital aspect of these training programs. Trainees typically engage in operating actual centerless grinders under the supervision of experienced instructors. This real-world training allows participants to understand the intricacies of setup, adjustments, and troubleshooting. Learning to precisely adjust the blade angles, feed rates, and workpiece positioning is crucial, as these factors directly impact the quality and accuracy of the finished product.

centerless grinder training company

Moreover, emphasis is placed on safety practices and maintenance routines. Operators must be aware of potential hazards associated with grinding machinery and learn how to mitigate risks effectively. Regular maintenance is essential to prolong the life of the equipment and maintain high production standards. Training not only educates participants on operational techniques but also instills a strong sense of responsibility regarding machine upkeep and workplace safety.

In addition to technical skills, training programs often highlight the importance of quality control in the grinding process. Trainees learn to utilize various measurement tools and techniques to ensure that the workpieces meet specified tolerances and surface finish standards. Understanding how to interpret measurement results and make necessary adjustments is pivotal in achieving the desired outcomes.

By investing in centerless grinder training, companies can ensure that their operators are not only skilled but also versatile in handling a variety of grinding tasks

. This training leads to improved efficiency, reduced downtime, and enhanced product quality, benefiting the entire manufacturing process.In conclusion, centerless grinder training is more than just a technical education; it is an investment in precision manufacturing and quality assurance. As industries continue to demand high-performance components, well-trained operators will play a crucial role in meeting these challenges head-on.