The Rise of Centerless Grinder Manufacturers A Focus on Tiger Stripe Technology

In the ever-evolving landscape of manufacturing, precision and efficiency are key drivers for success. One of the standout innovations in this realm is the development of centerless grinders. These machines, integral to the production of precision components, have seen significant advancements in technology and application, particularly with the advent of what is now popularly referred to as Tiger Stripe technology.

Understanding Centerless Grinding

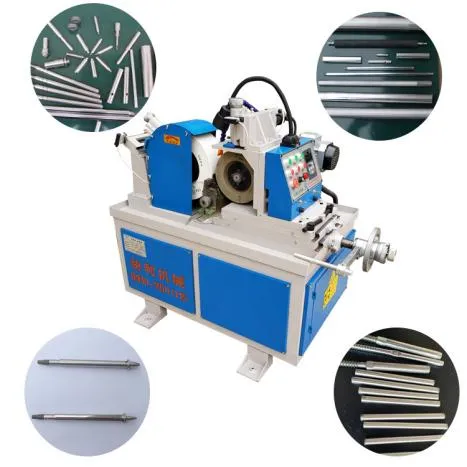

Centerless grinding is a machining process that is used to finely grind a cylindrical object. Unlike traditional grinding, where the workpiece is held in place between two centers, a centerless grinder utilizes a different approach. The workpiece is placed on a work rest blade and is secured by an abrasive wheel and a regulating wheel. This design not only allows for higher efficiency but also facilitates the grinding of longer, more complex shapes without the need for support on both ends.

The Emergence of Tiger Stripe Technology

The term Tiger Stripe refers to a specific feature in some of the latest centerless grinding machines that enhances the abrasive grinding process. The technology is characterized by a unique pattern of abrasive grains that resemble the distinctive stripes of a tiger. This pattern significantly improves the grinding performance by optimizing the contact surface between the grinding wheel and the workpiece.

Manufacturers employing Tiger Stripe technology report enhanced grinding precision, reduced wear on wheels, and improved overall surface finish of the machined parts. This innovation has become a game-changer in industries that require stringent precision standards, such as aerospace, automotive, and medical device manufacturing.

Key Manufacturers Leading the Charge

As the demand for high-precision components grows, several manufacturers have emerged as leaders in the centerless grinding market, particularly those integrating Tiger Stripe technology into their products.

1. Jones & Shipman A legacy name in the grinding industry, Jones & Shipman has incorporated Tiger Stripe technology into their range of centerless grinders. Their machines are recognized for their durability, precision, and ability to handle diverse materials.

centerless grinder tiger stripe manufacturers

2. Royal Master Grinders Based in New Jersey, Royal Master Grinders has a reputation for innovation in grinding technology. Their commitment to research and development has led to the successful integration of Tiger Stripe technology, enhancing their machines' performance in achieving tighter tolerances.

3. Koyo Machinery A major player in the global market, Koyo has been at the forefront of grind-based solutions. Their centerless grinders with Tiger Stripe technology are designed to meet the rigorous demands of various sectors, offering greater flexibility and adaptability.

4. Cincinnati Machines Known for their robust construction and cutting-edge technology, Cincinnati Machines have also adopted Tiger Stripe technology in their centerless grinders. Their focus on precision and stability has made them a preferred choice among manufacturers.

The Advantages of Tiger Stripe Centerless Grinders

The benefits of Tiger Stripe technology extend beyond just improved grinding performance. Here are some key advantages

- Increased Efficiency The unique abrasive grain arrangement allows for faster material removal rates, accelerating production times without compromising quality. - Enhanced Lifespan of Grinding Wheels The optimized contact surface reduces wear and tear on grinding wheels, leading to reduced operational costs and longer equipment life.

- Superior Surface Finish Components produced through this innovative technology exhibit a smoother surface finish, which is crucial in applications where aesthetics and performance are paramount.

- Versatility Tiger Stripe centerless grinders can accommodate a variety of materials, making them suitable for diverse industries—from small-scale operations to large manufacturing plants.

Conclusion

As technology continues to evolve, the introduction of advanced features like Tiger Stripe in centerless grinders showcases the manufacturing industry's commitment to precision and quality. With leading manufacturers at the helm, the impact of this technology will likely resonate across multiple sectors, leading to improved production processes, enhanced component quality, and a better return on investment. It’s clear that as we move forward, centerless grinding will remain a cornerstone of efficient and precise manufacturing, driven by innovations like Tiger Stripe technology.