Understanding Centerless Grinder Service Ensuring Precision and Performance

The world of manufacturing and machining is characterized by the need for precision and efficiency. Among the various tools used in this domain, centerless grinders play a pivotal role in achieving high tolerances and exceptional surface finishes. However, to maintain optimal performance, regular service and maintenance of these machines are crucial. In this article, we will delve into the significance of centerless grinder service, its components, and best practices to ensure your machinery runs smoothly.

What is a Centerless Grinder?

Centerless grinders are specialized machines used for grinding cylindrical workpieces without the need for a center hold. This unique design allows for continuous grinding operations, maximizing productivity. Typically, a workpiece is held in place by two rotating wheels – a grinding wheel and a regulating wheel. The precision with which these components are aligned and maintained directly influences the quality of the finished product.

The Importance of Regular Service

Just like any other machine, centerless grinders require routine servicing to ensure they perform at their best. Regular service helps to

1. Enhance Efficiency A well-maintained machine operates more efficiently, reducing downtime and increasing throughput. When components are fresh and calibrated, the likelihood of errors during production diminishes significantly.

2. Improve Precision Centerless grinding is all about precision. Service routines help to ensure that the grinding and regulating wheels are properly aligned and dressed, minimizing variances in the final dimensions of the workpiece.

3. Extend Equipment Life Regular service can help identify and rectify small issues before they escalate into major breakdowns. This proactive approach extends the life of the grinder, ultimately saving costs on replacements and extensive repairs.

4. Ensure Safety Grinding machines can pose safety risks if not properly maintained. Regular checks can help identify worn-out parts or potential hazards, ensuring a safe working environment for operators.

Key Components of Centerless Grinder Service

To effectively service a centerless grinder, various components require attention

- Grinding Wheel and Regulating Wheel These are the critical components responsible for shaping and finishing the workpiece. Regular dressing of the wheels is necessary to maintain their sharpness and efficiency.

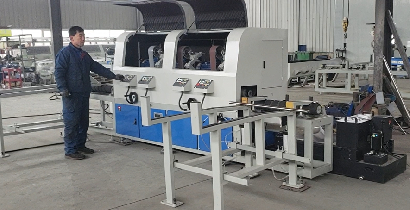

centerless grinder service

- Bearing and Spindle Maintenance The grinder’s precision is largely dependent on the condition of its bearings and spindle. Regular lubrication and checks for wear are essential to prevent wobbling and ensure smooth operation.

- Alignment and Calibration Over time, the alignment of the wheels can shift. Routine checks and calibrations are necessary to ensure that both wheels are perfectly aligned, contributing to consistent grinding results.

- Hydraulic Systems Many centerless grinders utilize hydraulic systems to maintain pressure on the workpieces

. Regular inspection of these systems can prevent hydraulic failures, ensuring seamless operation.Best Practices for Centerless Grinder Service

To achieve the best outcomes from your centerless grinder, consider adopting the following best practices

1. Scheduled Maintenance Implement a proactive maintenance schedule that includes routine checks and servicing intervals. This could be monthly or quarterly depending on usage.

2. Operator Training Ensure that all operators are trained in the proper usage and maintenance of the grinder. Knowledgeable operators can identify issues early and take preventive measures.

3. Use Quality Parts When replacement parts are necessary, always opt for high-quality, OEM (Original Equipment Manufacturer) parts to ensure compatibility and longevity.

4. Document Repairs and Maintenance Keeping detailed records of all service activities can help diagnose recurring issues and improve overall maintenance strategies.

5. Seek Professional Help For comprehensive servicing, consider enlisting the expertise of specialized technicians who understand the intricacies of centerless grinders.

Conclusion

In conclusion, centerless grinder service is an essential aspect of maintaining these intricate machines. By adhering to regular servicing protocols, manufacturers can ensure that their grinders operate efficiently, produce high-quality workpieces, and ultimately contribute to improved productivity and cost-effectiveness. In a competitive manufacturing landscape, investing in proper service and maintenance of centerless grinders can make a significant difference in operational success.