Centerless Grinder Regulating Wheels Manufacturers An Overview

In the world of manufacturing and precision machining, the centerless grinding process stands out as one of the most efficient methods for shaping and finishing cylindrical components. At the heart of this process are the regulating wheels, which play a critical role in controlling the speed and movement of the workpiece during grinding. As such, the manufacturers of centerless grinder regulating wheels are essential to ensuring the performance and success of centerless grinding operations.

Understanding Centerless Grinding

Before diving into the specifics of regulating wheels manufacturers, it’s paramount to understand what centerless grinding entails. Unlike conventional grinding methods, centerless grinding does not require the workpiece to be mounted on a spindle. Instead, it relies on two wheels the grinding wheel and the regulating wheel. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the feed rate and rotational speed of the workpiece.

This system offers remarkable benefits, such as increased throughput and improved finish quality, making it a go-to option for manufacturers looking to produce high-precision components at scale. However, the effectiveness of centerless grinding largely depends on the quality and design of the regulating wheels.

The Role of Regulating Wheels

Regulating wheels are designed to grip and rotate the workpiece, guiding it through the grinding process. These wheels must be manufactured to precise specifications to ensure they provide the necessary friction and control required for effective grinding. Key factors, such as hardness, surface texture, and material composition, influence the performance of regulating wheels.

Common materials used in the production of regulating wheels include rubber, polyurethane, and various composite materials. Each material has distinct properties, which can significantly impact grinding accuracy, work-piece quality, and tool longevity. Consequently, manufacturers must carefully consider these factors when designing and producing regulating wheels.

Leading Manufacturers in the Industry

A variety of manufacturers specialize in the production of centerless grinder regulating wheels. These companies often leverage advanced technology, skilled craftsmanship, and rigorous quality control measures to ensure their products meet demanding industry standards. Here are a few notable manufacturers recognized for their contributions to the market

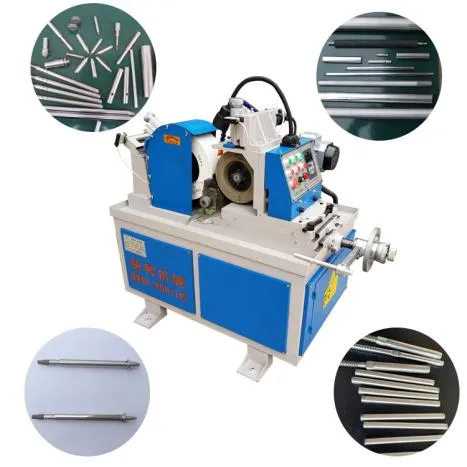

centerless grinder regulating wheels manufacturers

1. Crown Grinding Machines Renowned for their innovative designs and high-quality products, Crown Grinding Machines offers a range of regulating wheels that cater to various grinding applications. Their focus on customization allows them to provide tailored solutions for specific industry needs.

2. Centerless Grinding Solutions As a key player in the centerless grinding sector, this company specializes in creating both grinding and regulating wheels. Their commitment to research and development has positioned them at the forefront of technology, offering products that enhance grinding efficiency.

3. Fives Landis Corp. With a long-standing reputation for excellence, Fives Landis Corp. manufactures a range of grinding solutions, including highly engineered regulating wheels. Their approach emphasizes durability and precision, ensuring optimal performance in demanding environments.

4. National Grinding Wheel Known for their extensive catalog of grinding wheels, National Grinding Wheel also produces high-quality regulating wheels. Their dedication to using premium materials and advanced manufacturing techniques ensures product reliability and performance.

Innovations and Trends

The manufacturing landscape is constantly evolving, and so are the technologies related to centerless grinder regulating wheels. Advances in materials science, such as the development of new composites and polymers, are leading to wheels with enhanced performance characteristics. Additionally, manufacturers are increasingly adopting automation and precision engineering techniques, which contribute to higher production efficiency and reduced lead times.

Sustainability is another growing trend within the industry. Many manufacturers are exploring eco-friendly materials and processes to minimize their environmental impact while maintaining product quality. This shift not only aligns with global sustainability goals but also appeals to environmentally-conscious consumers.

Conclusion

Centerless grinder regulating wheels are vital components in the machining and manufacturing industries. The manufacturers producing these wheels play a crucial role in the overall efficiency and precision of centerless grinding processes. As the industry continues to innovate and adapt to new technologies and demands, the importance of high-quality regulating wheels remains steadfast. Whether through advancements in materials, automation, or sustainability efforts, these manufacturers are essential to the future of precision engineering and machining.