Centerless Grinder Precision Grinding Finding the Right Supplier

In the field of manufacturing and metalworking, precision grinding plays a crucial role in achieving the highest quality finishes and tolerances. One of the most efficient techniques for achieving these standards is through the use of centerless grinders. As industries continue to evolve, the demand for precision components is on the rise, making it essential for businesses to find reliable suppliers of centerless grinding services.

Understanding Centerless Grinding

Centerless grinding is a versatile machining process used to shape and finish metallic workpieces. Unlike traditional grinding methods, which involve positioning the workpiece between two centers, centerless grinding allows the workpiece to be supported by a combination of a grinding wheel and a regulating wheel. This setup not only enhances precision but also improves the efficiency of the grinding process, making it ideal for high-volume production.

The primary advantage of centerless grinding is its ability to produce parts with precise diameters and smooth finishes without the need for extensive setup. This process is particularly useful for components that require significant roundness and stability, such as shafts, pins, and tubes.

Key Considerations When Choosing a Supplier

When seeking a supplier for centerless grinding services, there are several key factors to consider

1. Expertise and Experience It’s essential to choose a supplier with a proven track record in precision grinding. Look for companies that specialize in centerless grinding and have extensive experience in working with various materials and components.

2. Quality Assurance Precision is paramount in grinding applications. A reliable supplier should have stringent quality control measures in place to ensure that every part meets industry standards. Ask about their certification processes and quality assurance protocols.

3. Equipment and Technology The quality of grinding is highly dependent on the machines used. Research the supplier’s equipment and technology. Advanced machinery that employs the latest grinding technology can significantly enhance surface finishes and dimensional tolerances.

4. Customization Capabilities Depending on your project requirements, you may need custom grinding solutions. Choose a supplier who offers flexibility and is willing to work closely with you to understand your specific needs and provide tailored solutions.

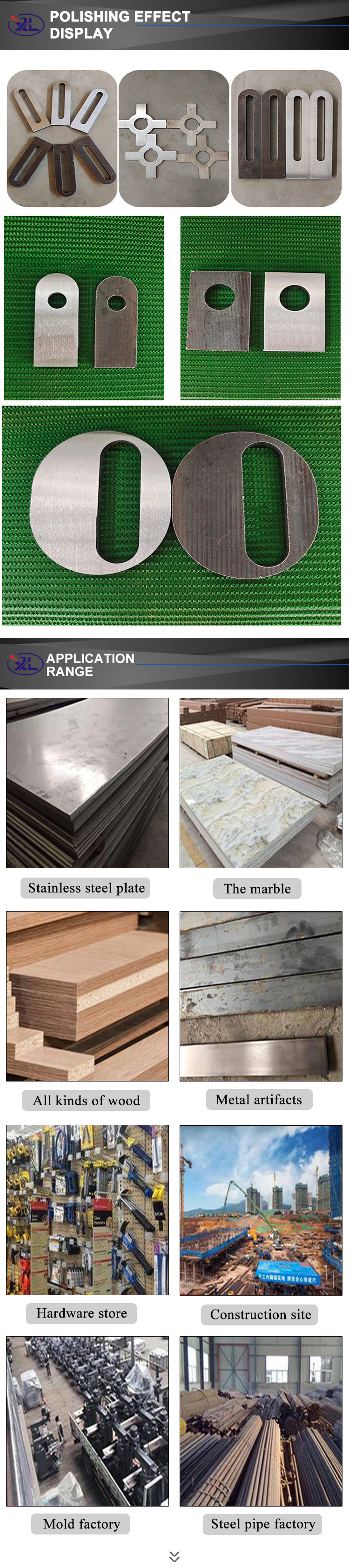

centerless grinder precision grinding supplier

5. Lead Times and Capacity Consider the supplier's production capacity and lead times. In today’s fast-paced market, delays can lead to significant costs. A supplier that can efficiently manage larger volumes without sacrificing quality will be a valuable partner.

6. Reputation and Reviews Conduct research on potential suppliers. Look for customer reviews, testimonials, and case studies. A company with a strong reputation in the industry is more likely to meet your expectations and deliver reliable service.

The Benefits of Partnering with a Precision Grinding Supplier

Collaborating with a specialized centerless grinding supplier can provide numerous benefits to your manufacturing processes

- Improved Efficiency With advanced equipment and experienced operators, these suppliers can optimize processing times, reducing overall lead times and costs.

- Cost-Effectiveness Outsourcing precision grinding can be more cost-effective than investing in in-house equipment and training. This allows businesses to allocate resources to other critical areas.

- Access to Expertise Through partnership, you gain access to a wealth of knowledge and expertise in grinding techniques, materials, and best practices that can help improve your product quality.

- Focus on Core Competencies By outsourcing non-core processes like grinding, your business can focus on its primary strengths, improving overall productivity and efficiency.

Conclusion

In the competitive landscape of manufacturing, the importance of finding a reliable centerless grinding supplier cannot be underestimated. By considering factors such as expertise, equipment quality, and customer feedback, businesses can make informed decisions that enhance their operations and product quality. The right supplier will not only meet your precision grinding needs but will also become a crucial partner in your journey toward excellence in manufacturing. Whether you are producing high volumes of standardized components or specialized custom parts, the right centerless grinder precision grinding supplier can make all the difference.