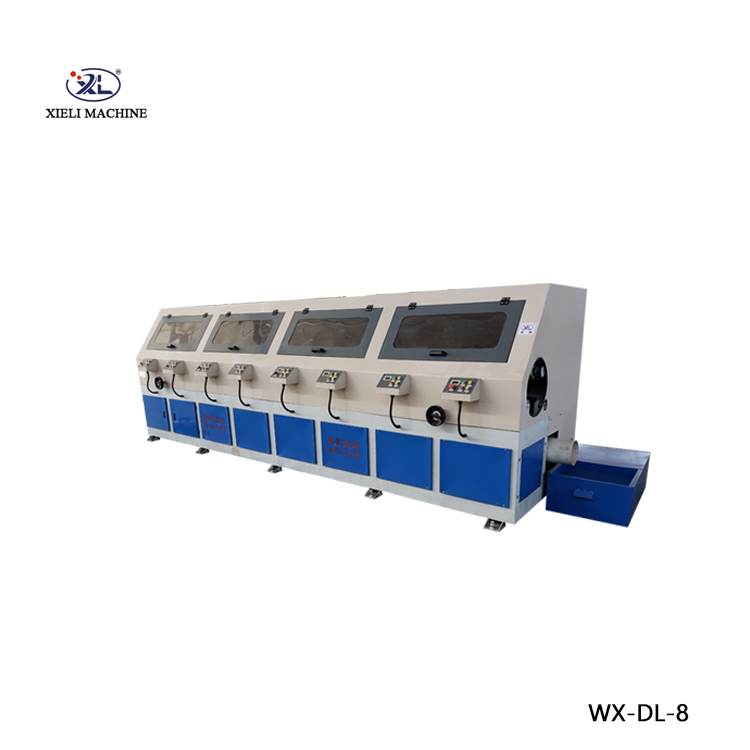

Centerless Grinder Precision Grinding Service

In the world of manufacturing, precision and accuracy are paramount. Centerless grinding is a highly effective method used to achieve these qualities, especially when dealing with cylindrical parts. This grinding technique stands out for its ability to produce components with tight tolerances and excellent surface finishes, making it a popular choice in various industries.

Centerless grinding operates on a simple principle the workpiece is held in place between two grinding wheels, one of which is stationary while the other rotates

. This setup allows for continuous material removal without the need for complex fixtures or setups, making it an efficient option for high-volume production. The process not only ensures uniformity in the dimensions of the parts but also enhances their structural integrity.One of the key advantages of centerless grinding services is their versatility. They can accommodate a diverse range of materials—including metals, plastics, and composites—while producing parts in diverse shapes and sizes. This adaptability makes them ideal for numerous applications, from automotive and aerospace components to medical devices and industrial machinery.

centerless grinder precision grinding service

Quality control is critical in any machining process, and centerless grinding is no exception. Advanced CNC (Computer Numerical Control) systems and in-process gauging are often employed to monitor the grinding operation continuously. This ensures that each part meets the specified dimensions and surface finish requirements. Companies offering precision grinding services often adhere to strict quality management systems, which can include ISO certifications, to guarantee that they deliver top-notch products to their customers.

Moreover, the economic benefits of centerless grinding are significant. Since the process is highly automated and can be run in a continuous cycle, production rates are increased while labor costs are decreased. This efficiency translates to lower prices for high-quality precision parts, making it an attractive option for manufacturers looking to optimize their operations.

In conclusion, centerless grinder precision grinding services play a crucial role in various sectors of industry, offering enhanced performance, versatility, and cost-effectiveness. As technology advances, these services continue to evolve, providing manufacturers with innovative solutions to their grinding needs. Whether it’s for mass production or bespoke components, centerless grinding stands out as a reliable method for achieving superior precision and quality. Choosing the right service provider ensures that businesses not only meet their production goals but also maintain the high standards expected in today’s competitive market.