Exploring the World of Centerless Grinder Parts Manufacturing

Centerless grinding is an essential process in industrial manufacturing, particularly known for its efficiency in producing precision parts. Unlike traditional grinding methods, centerless grinding allows for continuous workpiece feeding without the need for fixed support. This process is pivotal in various sectors such as automotive, aerospace, medical, and electronics, where high precision and optimal surface finishes are crucial. Central to the success of this process are the components that make up a centerless grinder, which is why the factory that produces these parts plays a vital role.

Understanding Centerless Grinders

To fully appreciate the importance of the factory that manufactures centerless grinder parts, one must first understand the workings of these machines. A centerless grinder typically comprises three main components the grinding wheel, the regulating wheel, and the work rest blade. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the feed rate and rotation of the workpiece. The work rest blade serves to support the workpiece throughout the grinding process.

These components must be engineered with precision and manufactured from high-quality materials to ensure durability and effectiveness. The factory responsible for producing these parts must maintain high standards of quality control and utilize advanced manufacturing techniques to produce components that meet the rigorous demands of modern machining.

The Manufacturing Process

The manufacturing of centerless grinder parts begins with selecting appropriate materials, which is critical to the performance of the final product. Common materials include high-speed steel and various alloys that can withstand the heat and pressure generated during grinding. These materials undergo processes such as forging, casting, and machining to achieve the desired shapes and properties.

Advanced Computer Numerical Control (CNC) machines are often used in manufacturing to ensure precision in every component. CNC technology allows for intricate designs and consistent production quality, minimizing the variation between parts. This is especially important for components like the grinding and regulating wheels, where even minor discrepancies can lead to significant performance issues.

Once the parts are machined, they undergo a rigorous quality assurance process. This includes inspections using precision measurement tools such as micrometers and coordinate measuring machines (CMMs). Any defective components are identified and discarded or reworked, ensuring only the highest quality parts make it to assembly.

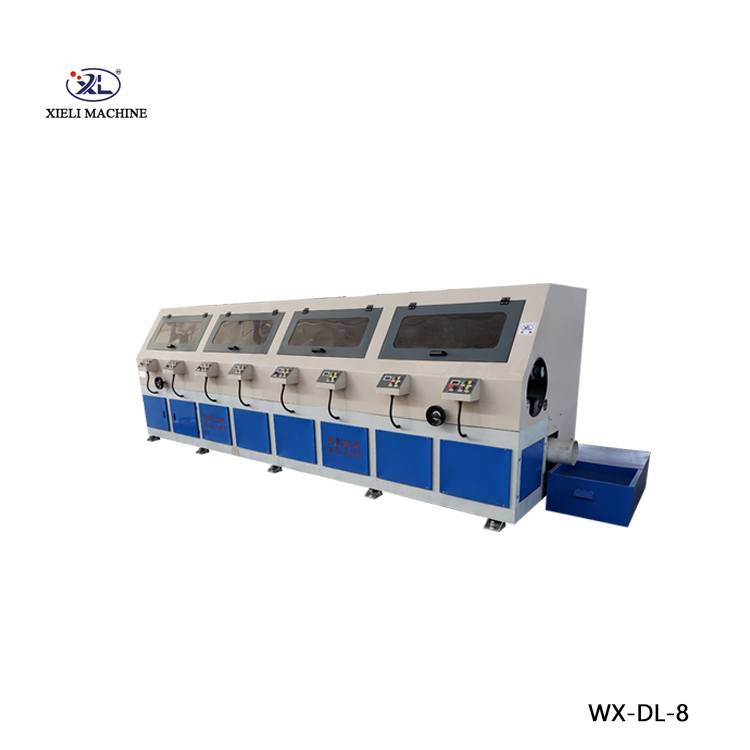

centerless grinder parts factory

The Role of Innovation

Innovation is a driving force in the manufacturing of centerless grinder parts. As industries evolve and demand increases for more precise and efficient grinding processes, manufacturers must adapt. Emerging technologies like additive manufacturing and advanced robotics are being integrated into production lines to enhance efficiency and reduce waste.

Additive manufacturing, or 3D printing, is particularly promising, allowing the design of complex geometries that were previously difficult to achieve with traditional methods. This can lead to lighter and stronger components, providing better performance in grinding applications. Furthermore, automation through robotics can significantly increase production speed while maintaining consistent quality, which is paramount in high-volume manufacturing environments.

Sustainability in Manufacturing

In today's manufacturing landscape, sustainability is becoming increasingly important. Factories producing centerless grinder parts are exploring eco-friendly practices, from sourcing sustainable raw materials to implementing energy-efficient processes. Reducing carbon footprints and waste is essential not only for compliance with regulations but also for meeting the growing consumer demand for sustainability.

Many manufacturers are investing in recycling programs for scrap materials generated during the machining process. Additionally, adopting energy-efficient machinery and techniques helps reduce overall power consumption and greenhouse gas emissions.

Conclusion

The factory that produces centerless grinder parts is more than just a facility; it is a hub of innovation, precision, and sustainability. The crucial components manufactured within these walls ensure the smooth operation of centerless grinding, which, in turn, plays a significant role in various high-precision industries. As technology continues to advance, so too will the methodologies employed in these factories, leading to even greater efficiencies and capabilities in the future. The commitment to quality, innovation, and sustainability will ensure that the manufacturing of centerless grinder parts remains at the forefront of industrial machining for years to come.