The Centerless Grinder Market An Overview of Key Players and Trends

The centerless grinder market is an integral segment of the global manufacturing landscape, specializing in the creation of precision components that are essential across various industries, including automotive, aerospace, medical devices, and electronics. Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece, providing a high level of accuracy and efficiency, particularly for cylindrical shapes. As industries continue to demand more precision and efficiency, the market for centerless grinders is experiencing significant growth.

Key Players in the Centerless Grinder Market

The centerless grinder market is characterized by a mix of established companies and emerging players. Key industry players include

1. KNGD (Koyo Machinery USA) KNGD is renowned for its wide range of precision grinding machines, including centerless grinders. The company is known for its focus on innovation and customer support.

2. Cincinnati Grinder A historic name in the grinding equipment sector, Cincinnati offers high-quality centerless grinding solutions that are integral to various manufacturing processes.

3. Butler With decades of experience, Butler specializes in customized grinding solutions, catering to specific needs of clients across different industries.

4. Schaudt Mikrosa This company is recognized for its advanced technology and precision machinery, providing innovative solutions in the realm of centerless grinding.

These companies have been pivotal in shaping the market landscape through continuous innovation, robust product offerings, and extensive customer engagement.

Market Trends and Growth Drivers

centerless grinder market company

Several trends are shaping the centerless grinder market, fostering its growth and evolution.

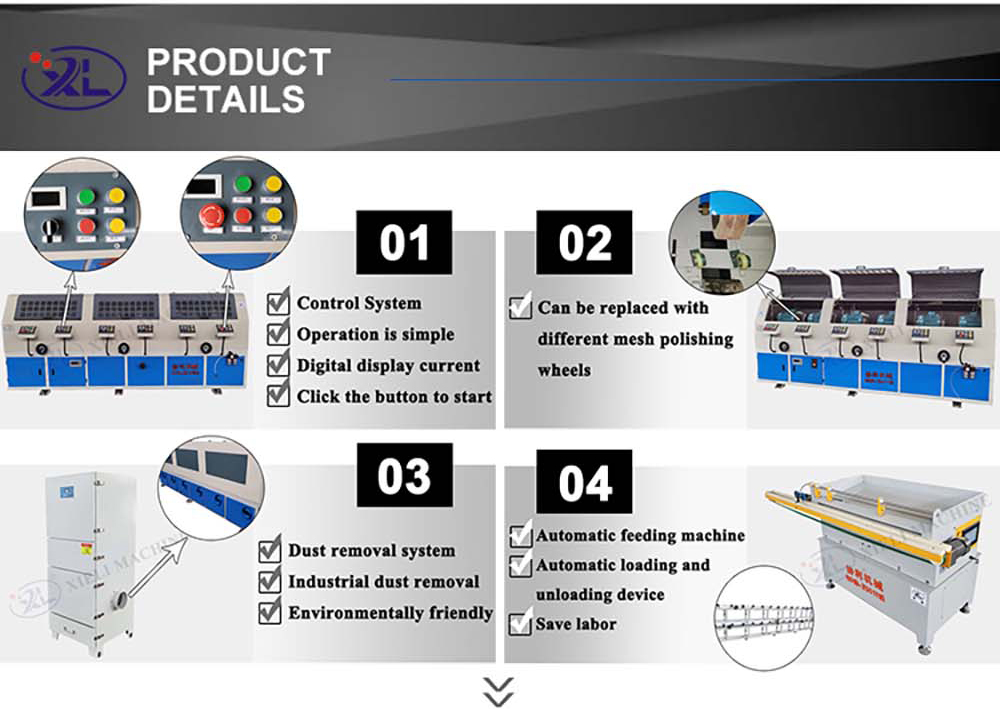

1. Technological Advancements The introduction of advanced technologies, such as automation and digitalization, has enhanced the performance of centerless grinders. Features like CNC (Computer Numerical Control) programming and integrated monitoring systems allow for higher precision, reduced cycle times, and improved operational efficiency.

2. Integration of Industry 4.0 The shift towards smart manufacturing has encouraged the incorporation of Industry 4.0 technologies in centerless grinding. This includes the use of IoT (Internet of Things) for real-time monitoring and data collection, enabling predictive maintenance and optimizing machine performance.

3. Growing Demand for Precision Machinery As manufacturing processes become more complex and the need for high-precision components intensifies, centerless grinders are increasingly being adopted. Industries such as automotive and aerospace require stringent tolerances, which centerless grinding can provide efficiently.

4. Sustainability and Eco-friendliness The rise of eco-friendly manufacturing practices is influencing the design of centerless grinders. Companies are investing in machinery that reduces waste and energy consumption, aligning with Global Sustainable Development Goals.

5. Market Expansion in Emerging Economies Developing countries are witnessing rapid industrialization, leading to an increased demand for manufacturing equipment, including centerless grinders. As these nations grow, they present lucrative opportunities for market players.

Challenges in the Centerless Grinder Market

Despite the growth prospects, the centerless grinder market faces several challenges. Fluctuating raw material prices can affect manufacturing costs, while the need for skilled labor poses a barrier for some manufacturers in adopting advanced grinding technologies. Moreover, the intense competition among existing players necessitates constant innovation and differentiation strategies.

Conclusion

The centerless grinder market is poised for growth, driven by technological advancements, the increasing demand for precision machinery, and the expanding manufacturing base in emerging economies. Key players in the market are continuously innovating to meet evolving industry requirements while addressing challenges related to costs and labor. As the landscape of manufacturing evolves, centerless grinders will remain a vital component in producing high-quality, precise components essential for various applications across industries.