Overview of Centerless Grinder Manufacturers and Suppliers

Centerless grinding is a crucial manufacturing process used to shape and finish materials, primarily metals, with high precision and efficiency. In this process, the workpiece is supported by a regulating wheel and a grinding wheel, eliminating the need for a machine fixture or vise. This unique setup allows for continuous operation, making it a favored choice in various industries, including automotive, aerospace, and metalworking.

Given the significance of centerless grinding in modern manufacturing, the demand for reliable centerless grinder manufacturers and suppliers has grown significantly. In this article, we will explore the key aspects that characterize leading manufacturers and suppliers in this field, as well as the factors to consider when selecting a centerless grinder for your specific needs.

Key Characteristics of Leading Manufacturers

1. Innovation and Technology Leading centerless grinder manufacturers continually invest in research and development to enhance their machinery's capabilities. This includes integrating advanced technologies such as CNC (Computer Numerical Control) systems, allowing for improved precision, automation, and adaptability in various grinding operations.

2. Product Range Reputable manufacturers typically offer a wide range of centerless grinding machines tailored to different applications, from high-production models to more specialized machines for intricate grinding tasks. This versatility allows customers to select machines that best fit their operational requirements.

3. Quality and Reliability The quality of construction and components used in centerless grinders directly influences their performance and lifespan. Top manufacturers use high-grade materials and adhere to strict manufacturing standards, ensuring that their machines are not only efficient but also durable under challenging working conditions.

4. Customer Service and Support Effective customer service is a hallmark of reputable manufacturers. This includes pre-sales consultation, technical support, and post-sale services such as maintenance, training, and spare parts availability. Strong support networks can significantly impact operational uptime and overall satisfaction.

5. Customization Options Many industries have specific requirements regarding grinding processes. Leading manufacturers offer customization options to cater to these needs, whether it involves altering machine specifications or developing unique features for specialized applications.

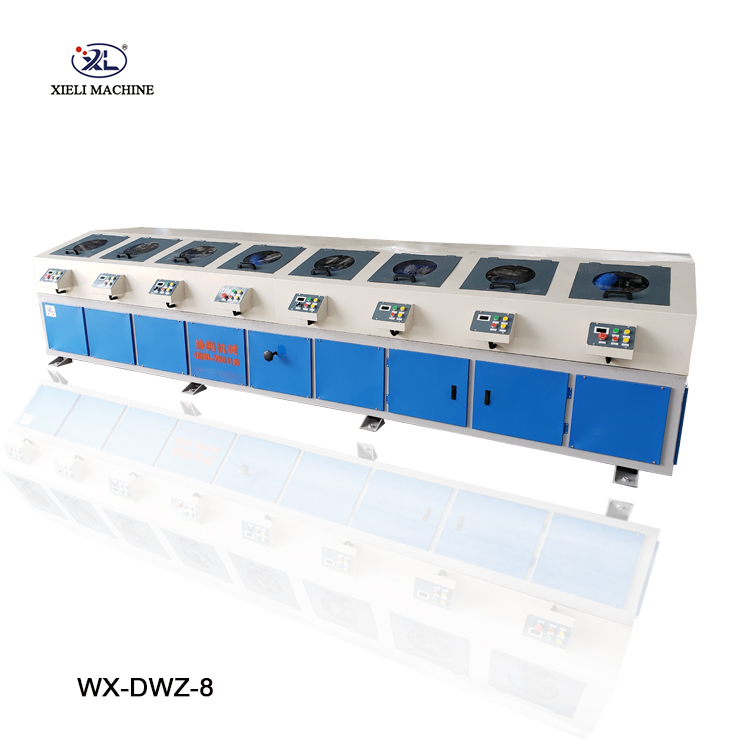

centerless grinder manufacturers suppliers

Importance of Suppliers

While manufacturers create the machines, suppliers play a pivotal role in ensuring that businesses can access the right equipment and support. A reliable supplier should have the following attributes

1. Wide Distribution Network Suppliers with a wide network can offer prompt service and deliver equipment quickly, which is essential for businesses needing immediate solutions.

2. Knowledgeable Staff Experienced suppliers who understand the technical aspects of centerless grinding can provide valuable guidance to customers, helping them choose the right machine and accessories.

3. After-Sales Service Just as crucial as product availability is after-sales service. Suppliers should be able to assist with installation, provide technical support, and offer training to ensure that operators can maximize the machine's capabilities.

4. Competitive Pricing In today's competitive market, suppliers should strive to offer competitive pricing without compromising on quality. This ensures that customers receive good value for their investment.

Conclusion

In conclusion, the choice of a centerless grinder manufacturer and supplier can significantly affect operational efficiency and productivity in any business that relies on precision machining. It is essential to consider factors such as technological advancements, product range, reliability, and customer service when selecting a manufacturer. Simultaneously, the supplier's capabilities—ranging from distribution to after-sales support—are equally important in ensuring successful machine integration into production lines. By focusing on these aspects, companies can foster long-term partnerships with reliable manufacturers and suppliers, leading to enhanced performance and competitive advantage in their respective markets.