Centerless Grinder Machine for Sale A Comprehensive Overview

In the realm of precision machining, the centerless grinder machine stands out as a crucial piece of equipment for many manufacturing processes. Unlike traditional grinding machines that utilize centers to hold the workpiece, centerless grinders allow for continuous production of round parts without the need for centering. This unique method not only increases productivity but also enhances the accuracy and efficiency of grinding operations. With an ever-growing demand for these machines, numerous companies are now offering centerless grinder machines for sale, catering to various industrial needs.

Understanding Centerless Grinding

Centerless grinding is primarily used for producing highly precise and uniformly finished cylindrical components. This method employs two wheels the grinding wheel and the regulating wheel. The workpiece is placed between these two wheels, and its rotation is controlled by the regulating wheel, while the grinding wheel shapes the part. This setup allows for high-speed operation and an uninterrupted workflow, making it an ideal choice for high-volume production environments.

Advantages of Centerless Grinding Machines

1. High Efficiency Centerless grinders are designed for mass production, making them highly efficient. They can quickly process a large number of parts, thereby significantly reducing manufacturing time. 2. Improved Accuracy The method ensures that each part is ground to a uniform size and finish, reducing variability and enhancing quality control.

3. Versatile Applications These machines are suitable for various materials, including metals, plastics, and composites. They can grind different shapes and sizes, making them versatile for many industries such as automotive, aerospace, and medical devices.

4. Reduced Labor Costs With automation technology intertwined in modern centerless grinders, there is less reliance on manual labor. This not only decreases operating costs but also increases safety in the workplace.

Finding the Right Centerless Grinder for Sale

When exploring the market for centerless grinder machines, there are several factors to consider

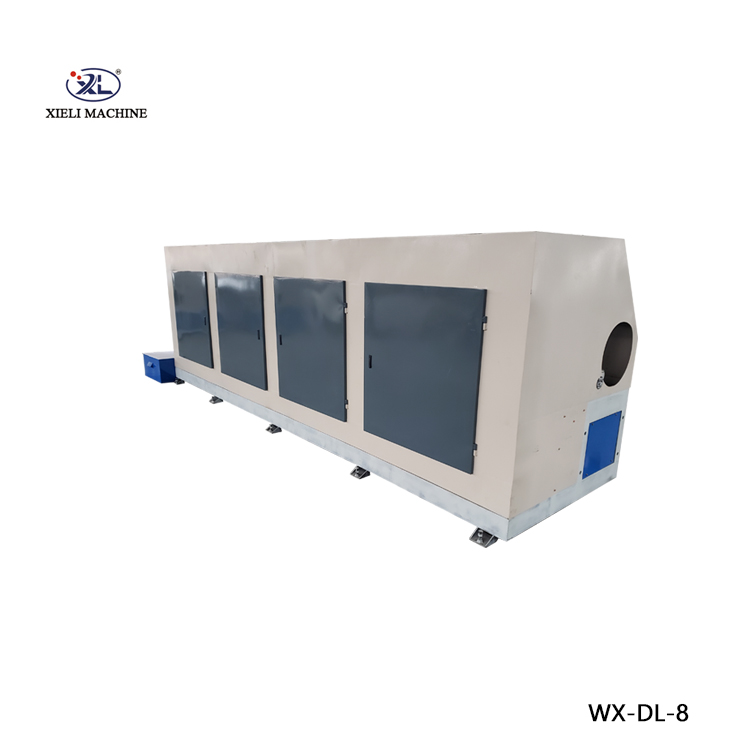

centerless grinder machine for sale companies

1. Specifications Pay attention to the size, power, and speed of the grinder. Ensure that the specifications align with your production requirements. Different models may cater to varied workpiece dimensions and materials.

2. Manufacturer Reputation Opt for reputable manufacturers known for their high-quality machinery. Look for companies with positive customer reviews and a strong track record in the industry.

3. Service and Support Consider the level of after-sales service and technical support offered by the vendor. Access to routine maintenance and spare parts is crucial for the sustained performance of your centerless grinder.

4. Investment Cost While it may be tempting to choose the least expensive option, weigh the cost against the machine's capabilities and the potential return on investment. In many cases, spending more upfront on a reliable and efficient machine can save money in the long run.

Leading Companies in the Centerless Grinder Market

Several companies have established themselves as leaders in the centerless grinder market, offering a range of machines to suit different industry needs. Some of these companies include

- Royal Master Grinders Known for their innovative designs and cutting-edge technology, Royal Master provides options for both manual and automated centerless grinders. - Koyo Machinery A respected name in grinding technology, Koyo offers versatile centerless grinder solutions ideal for both high-volume and precision grinding operations.

- Cincinnati Machines With a long-standing reputation in the machinery industry, Cincinnati Machines produces durable and efficient centerless grinders suitable for various manufacturing applications.

Conclusion

Centerless grinder machines play an integral role in today’s manufacturing landscape, offering significant advantages in terms of efficiency, accuracy, and versatility. As industries continue to evolve, the demand for high-quality centerless grinders will only increase. For companies looking to invest in these machines, careful consideration of specifications, manufacturer reputation, and support options will lead to informed purchasing decisions. Whether you’re in automotive, aerospace, or any sector requiring precision grinding, investing in a reliable centerless grinder can be a game-changer for your production capabilities.