The Global Market for Centerless Grinder Machine Exporters

In the ever-evolving landscape of manufacturing, centerless grinding technology has carved a niche for itself due to its precision and efficiency. Centerless grinder machines are essential tools in various industries, from automotive to aerospace, where tight tolerances and high production rates are paramount. As global demand for these machines continues to rise, exporters of centerless grinders play a crucial role in meeting the needs of manufacturers worldwide.

Centerless grinding is a machining process that removes material from a workpiece using abrasive wheels. Unlike traditional grinding, where the workpiece is held in place between two centers, centerless grinding allows for the workpiece to be fed through the grinding wheels, making it a highly efficient way to process round parts. This method significantly reduces setup times and enables manufacturers to produce large quantities of parts quickly and accurately. As industries strive for greater efficiency, the demand for centerless grinder machines has surged, prompting exporters to capitalize on this trend.

The centerless grinder machine market is characterized by a variety of players, ranging from small-scale manufacturers to large multinational corporations. Exporters of centerless grinders can be found in numerous countries, with major hubs located in the United States, Germany, Japan, and China. These countries have well-established manufacturing capabilities and supply chains that allow them to produce high-quality machines that are sought after in global markets.

One of the critical factors driving the growth of centerless grinder machine exporters is the rising demand for precision-engineered components. As industries such as automotive and aerospace evolve, the need for components that meet stringent quality standards has never been greater. Centerless grinding machines are capable of achieving tolerances as tight as a few microns, making them ideal for producing critical components such as shafts, pins, and bearings.

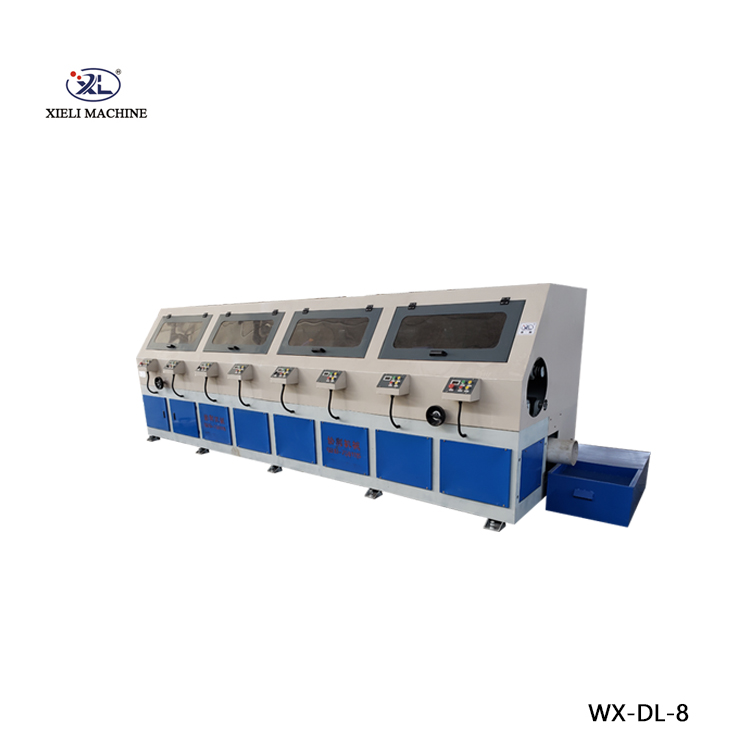

centerless grinder machine exporters

Moreover, the rise of automation and Industry 4.0 is transforming the manufacturing landscape. Exporters are increasingly offering advanced centerless grinding machines equipped with automation features such as robotics and software integration. These advancements not only enhance productivity but also reduce labor costs and minimize the risk of human error. As manufacturers look to modernize their processes, the demand for technologically advanced centerless grinders is expected to grow.

Geographically, the Asia-Pacific region is emerging as a significant market for centerless grinder machines. Countries like China and India are witnessing rapid industrialization and urbanization, leading to increased investments in manufacturing. As local manufacturers seek to enhance their production capabilities, the demand for centerless grinders is expected to rise. Exporters who can provide custom solutions tailored to the specific needs of these markets stand to gain a competitive edge.

However, exporters of centerless grinder machines also face challenges. Intense competition, both domestically and internationally, puts pressure on pricing and profitability. Additionally, fluctuations in raw material costs and supply chain disruptions can impact the manufacturing process. To navigate these challenges, exporters must prioritize quality, innovation, and customer service.

In conclusion, centerless grinder machine exporters are vital players in the global manufacturing sector. As demand for precision and efficiency continues to grow, these exporters are well-positioned to meet the needs of a dynamic market. By leveraging advanced technology and addressing the challenges of an ever-changing landscape, they can not only survive but thrive in this competitive arena. The future looks promising for those who can adapt and innovate, ensuring that centerless grinding remains an integral part of modern manufacturing processes.