For businesses in Livonia, Michigan, seeking reliable machining solutions, centerless grinders stand out as a pivotal choice in precision engineering. These machines offer exceptional capabilities for grinding processes that require removing materials without the need for a center. If you are considering investing in a centerless grinder or upgrading your current machinery, understanding the nuances of these machines can significantly impact your purchasing decisions and business operations.

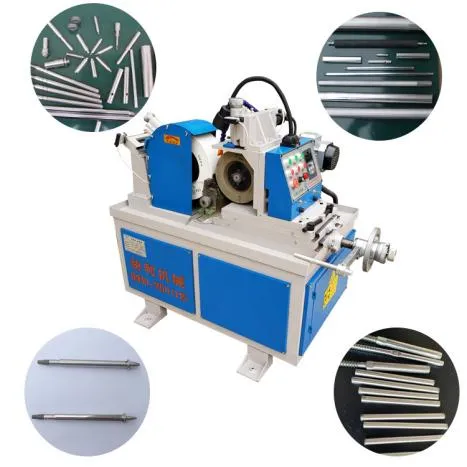

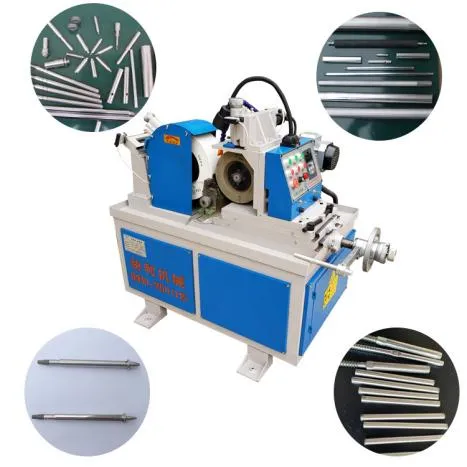

Centerless grinders essentially operate by utilizing two rotary wheels the grinding wheel, which does the actual removal of material, and the regulating wheel, which is responsible for setting the speed and rotation direction of the workpiece. This highly efficient process can rapidly yield precise cylindrical parts with a high-quality surface finish, making it indispensable in industries such as automotive, aerospace, and even healthcare for medical device manufacturing.

When seeking quotes for a centerless grinder in Livonia, Michigan, several factors should inform your decision-making process

1. Machine Configurations and Customizations Different applications require specific setups or customizations. Single-wheel or dual-wheel configurations might suit varied needs. Evaluate whether you need through-feed, in-feed, or end-feed type grinders based on your production requirements. Consulting with local experts who can analyze your production demands can ensure you get the most suitable machine configuration.

2. Technology and Innovation The technological advancement in centerless grinders has introduced features that substantially boost productivity and precision. CNC technology, for example, allows for automated control over machining parameters, enhancing repeatability and reducing human error. Investing in a technologically advanced grinder can lead to long-term savings and higher efficiency.

3. Vendor Reputation and Support Services The credibility and expertise of the supplier play a crucial role. Established companies with a robust track record in machine tools in Livonia are preferable. They not only supply genuine products but also offer post-sales support services such as installation, training, maintenance, and repairs, ensuring that your investment is well-protected.

centerless grinder livonia mi quotes

4. Material Compatibility Centerless grinders can handle a variety of materials from hard metals like steel to softer materials such as plastic. Ensure the machine you select can accommodate the specific materials you plan to work with, as this will influence both the grinder's longevity and the quality of outputs.

5. Cost Considerations and Efficiency Price is a pivotal factor, but the cheapest option is not always the most cost-effective in the long run. Factor in the operating costs, including energy consumption and anticipated maintenance expenses. Obtaining comprehensive quotes from different vendors in Livonia can help in making an informed financial decision.

A testimonial from a Livonia-based automotive parts manufacturer reflects the impact of choosing the right centerless grinder “We upgraded to a CNC centerless grinder last year, and the precision it delivers significantly reduced our defect rate. The operational speed has improved our overall production time, directly improving our bottom line.”

It is clear that businesses in Livonia can greatly benefit from understanding and leveraging the capabilities of centerless grinders. By focusing on the four pillars of Experience, Expertise, Authoritativeness, and Trustworthiness in the procurement process, companies can secure a competitive edge in their respective industries. Always prioritize working with reputable suppliers and staying abreast of technological advancements to optimize your machining operations effectively.

Livonia, with its burgeoning community of skilled machinists and robust industrial base, offers an ideal environment for businesses to explore and harness the full potential of centerless grinding technology, positioning themselves for future growth and success in an ever-evolving market landscape.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.