Centerless Grinders for Sale A Comprehensive Guide

In the realm of manufacturing and machining, precision is paramount. One of the most efficient solutions for achieving high-precision cylindrical grinding is the centerless grinder. This article aims to provide an overview of centerless grinders, their advantages, and tips for purchasing them.

Understanding Centerless Grinding

Centerless grinding is a machining process that involves the removal of material from a workpiece to achieve a precise diameter and finish. Unlike conventional cylindrical grinders, which require the workpiece to be centrally placed between two grinding wheels, centerless grinders hold the workpiece in place using a work rest blade, allowing it to be fed continuously through the grinder. This method not only increases productivity but also streamlines the grinding process, making it ideal for high-volume production.

There are two primary types of centerless grinders in-feed and through-feed. In-feed grinders are utilized for parts that require a specific width or length, while through-feed grinders handle longer, continuous workpieces. Both types offer unique benefits, catering to various manufacturing needs.

Advantages of Centerless Grinders

1. Increased Efficiency Centerless grinders can handle multiple parts simultaneously, vastly improving productivity compared to traditional methods.

2. High Precision These machines are designed to maintain tight tolerances, ensuring consistent quality in the finished products.

4. Versatility Centerless grinding can accommodate a wide range of materials, from hard metals to softer plastics, making it suitable for various industries, including automotive, aerospace, and medical manufacturing.

5. Cost-Effectiveness By reducing cycle times and increasing productivity, centerless grinders can lead to significant cost savings in the long run.

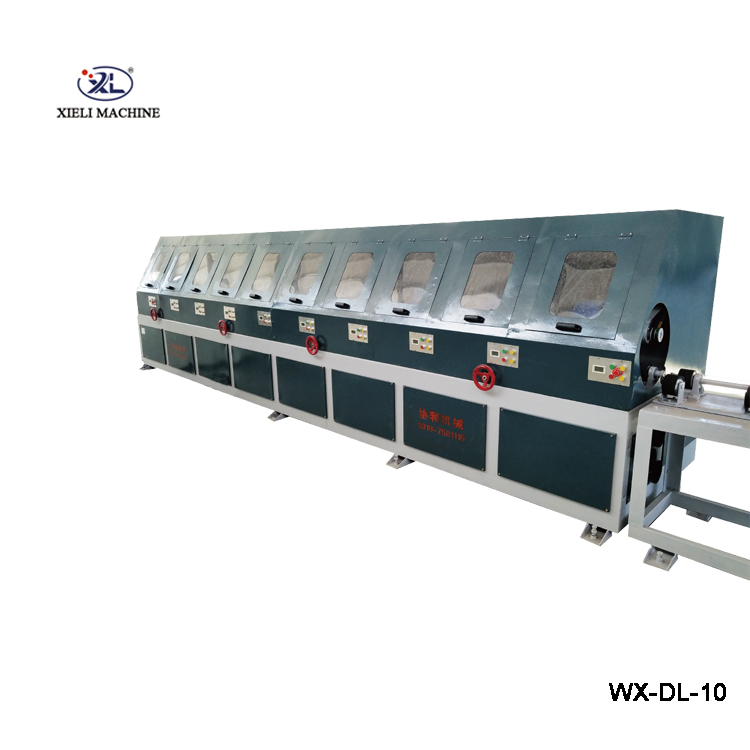

centerless grinder for sale

Finding Centerless Grinders for Sale

When searching for centerless grinders for sale, it is essential to evaluate specific factors to ensure that you are making a sound investment. Here are some tips

1. Assess Your Needs Determine the type of workpieces you will be processing and the required tolerances. Choose a grinder that fits your production volume and the nuances of your projects.

2. Research Brands and Models Familiarize yourself with reputable brands known for quality and durability in manufacturing centerless grinders. Popular manufacturers include Glebar, Royal Master, and Cincinnati Milacron.

3. Consider New vs. Used Machinery New centerless grinders come with the latest technology and warranties, but they can be expensive. Used grinders may offer significant savings, but it is crucial to inspect them for wear and performance capability.

4. Evaluate Features and Specifications Look for features such as adjustable work rests, coolant systems, and programmable controls. Specifications like wheel size, horsepower, and grinding capacity are also critical for meeting your production requirements.

5. Check for Service and Support Ensure that the manufacturer or dealer you are purchasing from offers reliable customer support, maintenance services, and access to replacement parts.

6. Budget Accordingly Establish a budget that encompasses not only the purchase price but also the costs of installation, training, and potential upgrades.

7. Request a Demonstration Whenever possible, request a demonstration of the grinder. This will allow you to see its capabilities firsthand and assess whether it meets your processing needs.

Conclusion

Investing in a centerless grinder can significantly enhance your manufacturing capabilities, providing improved efficiency and precision in your operations. By carefully evaluating your requirements and exploring various options, you can find the perfect machine that fits your production needs. Whether you're considering new or used equipment, understanding the market landscape and the specifics of centerless grinding will empower you to make an informed decision that boosts your business sustainability and competitiveness in an ever-evolving industrial environment.