Centerless Grinder Factories Pioneering Precision Machining

In the realm of precision machining, centerless grinders stand out as essential tools for achieving high levels of accuracy and efficiency in the production of cylindrical components. These machines operate without the need for a spindle, allowing for continuous grinding and the ability to process multiple parts simultaneously. This article explores the significance of centerless grinder factories, their operational mechanics, applications, and the evolving market landscape.

Centerless grinding is a method that enables the machining of workpieces with high precision and a superior surface finish. Unlike traditional grinding methods that utilize a chuck or fixture, centerless grinding supports the workpiece between a grinding wheel and a regulating wheel. This design not only simplifies the setup process but also enhances throughput, making it particularly advantageous for high-volume manufacturing.

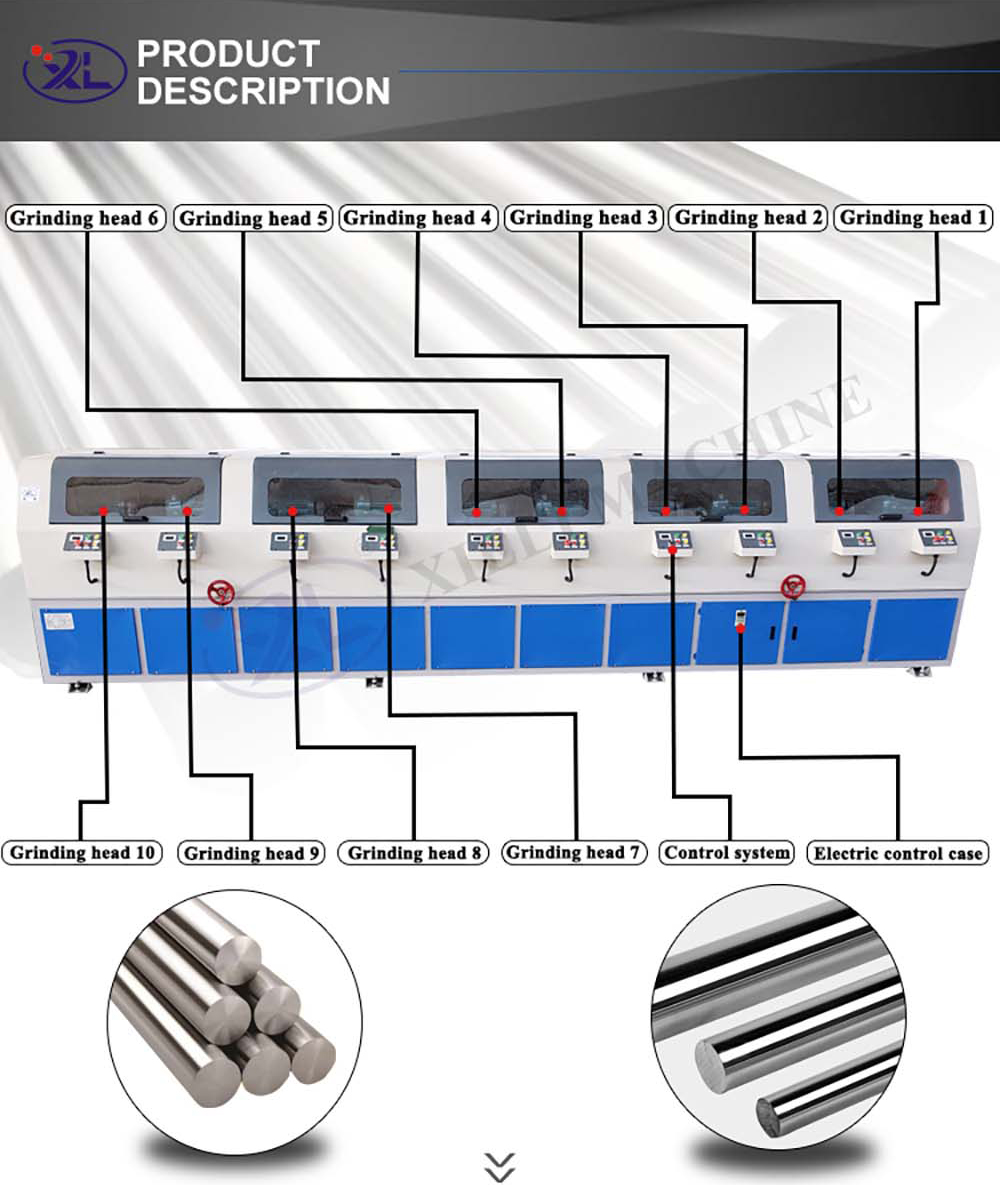

The heart of any centerless grinder factory is its machinery. These factories are equipped with advanced models that incorporate cutting-edge technology to optimize performance. Modern centerless grinders are designed with features such as programmable controls, automated in-feed and through-feed mechanisms, and advanced cooling systems to minimize thermal distortion. The integration of computer numerical control (CNC) systems allows for precision adjustments and complex machining operations, catering to diverse industrial needs.

One of the key advantages of centerless grinders is their versatility. They are capable of grinding various materials, including metals, plastics, and composites. This makes them valuable in a multitude of sectors, from automotive and aerospace to medical device manufacturing. In industries where tight tolerances and a smooth finish are paramount, centerless grinders play an indispensable role by ensuring that components meet stringent quality standards.

centerless grinder factories

The demand for centerless grinding has grown significantly in recent years, driven by the expansion of manufacturing sectors and advancements in technology. As industries evolve, so too do the requirements for precision parts. This has led to an increase in the establishment of centerless grinder factories, particularly in regions with a strong manufacturing base. Countries such as the United States, Germany, and Japan have seen a rise in investment in state-of-the-art facilities that focus on high-efficiency production.

Sustainability and environmental considerations are also influencing the operations of centerless grinder factories. Manufacturers are adopting greener practices by implementing energy-efficient machinery and reducing waste generated during the grinding process. The focus on sustainability not only meets regulatory demands but also appeals to an increasingly environmentally-conscious market.

Moreover, workforce training has become a priority for centerless grinder factories. As technology evolves, so does the skill set required to operate advanced grinding machines. Investing in human capital through training programs ensures that employees are adept at managing sophisticated machinery and maintaining quality control in the grinding process.

In conclusion, centerless grinder factories represent a critical segment of the precision machining industry. Their unique capabilities and high efficiency enable the production of quality components across various sectors. As technology continues to advance, and as sustainability becomes a focal point, these factories will undoubtedly play an integral role in shaping the future of manufacturing. The commitment to precision, efficiency, and innovation in centerless grinding will not only enhance productivity but also drive the industry's evolution in the years to come.