Centerless Grinder Coolant Suppliers An Essential Component for Precision Grinding

In the world of manufacturing, precision is paramount. One of the most critical processes that require this level of accuracy is centerless grinding. This method is widely used to produce high-precision components, and a crucial element of this process is the coolant—specifically, the suppliers of centerless grinder coolant. Understanding the role of coolant and the suppliers that provide it is vital for manufacturers who seek efficiency and quality in their grinding operations.

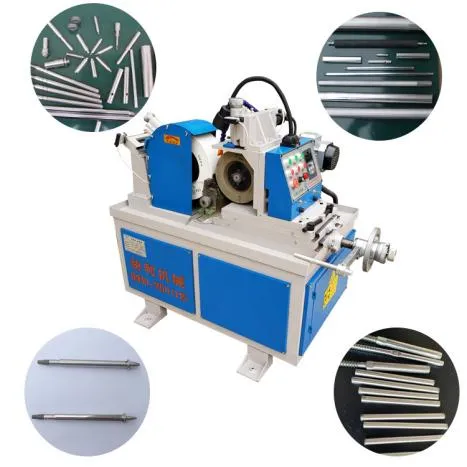

Centerless grinding is a technique where the workpiece is not fixed between centers; instead, it is supported by a regulating wheel and ground from the outside. This unique setup allows for continuous production and the ability to grind multiple parts simultaneously. However, it also generates significant heat due to friction, necessitating an efficient coolant system. Coolants serve multiple functions they reduce heat, lubricate the grinding wheel, flush away chips, and improve surface finish. Given these requirements, the choice of a reliable coolant supplier becomes crucial.

When looking for centerless grinder coolant suppliers, manufacturers should consider several factors, including product quality, variety, and technical support. High-quality coolants significantly enhance the performance of centerless grinders. They not only improve precision and prolong tool life but also ensure that the manufacturing process is both efficient and economical. Suppliers offering a variety of coolant formulations tailored for different materials and grinding conditions can better meet the diverse needs of manufacturers.

centerless grinder coolant suppliers

Furthermore, suppliers should provide technical support and guidance on the correct application and maintenance of their products. This support is particularly important in optimizing coolant performance and in troubleshooting potential issues that may arise during the grinding process. A knowledgeable supplier can help manufacturers select the right coolant for their specific applications, taking into account factors such as material type, grinding speed, and environmental conditions.

In recent years, there has been a growing emphasis on environmentally friendly coolants. Many suppliers are now offering biodegradable options that reduce the ecological impact of machining operations. Such sustainable alternatives not only cater to regulatory requirements but also align with the evolving values of modern businesses aiming for greener practices.

As the manufacturing industry continues to evolve, the role of centerless grinder coolant suppliers will remain crucial. Their products directly affect the efficiency and quality of grinding operations. Companies seeking to enhance their grinding processes should prioritize partnerships with reputable coolant suppliers who can provide high-quality products, technical expertise, and sustainable options.

In conclusion, centerless grinder coolant suppliers play an essential role in the manufacturing sector, particularly in precision grinding applications. By choosing the right supplier and coolant, manufacturers can improve their operational efficiency, reduce costs, and maintain high-quality standards in their products. As technology advances and new challenges arise, the importance of reliable coolant suppliers will only become more pronounced in this dynamic industry.