Exploring Cincinnati Products Centerless Grinders

When it comes to precision manufacturing, few machines are as indispensable as centerless grinders. Among the renowned names in this field, Cincinnati Products continues to stand out for its legacy in producing high-quality machinery that meets the diverse needs of various industries. This article delves into the intricacies of Cincinnati centerless grinders, their functionality, advantages, and applications.

Understanding Centerless Grinding

Centerless grinding is a specialized method that allows the efficient grinding of cylindrical parts without the need for centering the workpiece prior to grinding. In this process, the workpiece is held in place by a combination of a grinding wheel and a regulating wheel. The technology is especially favored for its ability to produce precise dimensions and superior surface finishes while minimizing manufacturing costs and processing time.

Cincinnati centerless grinders combine innovative engineering with advanced technology to deliver exceptional performance. The machines are designed to facilitate easy setup and operation, making them a popular choice for both large-scale manufacturers and smaller operations.

Key Features of Cincinnati Centerless Grinders

Cincinnati Products offers a range of centerless grinding machines, each equipped with a variety of features to cater to specific manufacturing needs. Some of the key features include

1. Versatile Grinding Capabilities Cincinnati grinders are capable of handling a wide range of material types and sizes, allowing manufacturers to work with everything from small precision components to larger pieces.

2. Precision Control Systems Modern Cincinnati centerless grinders come with advanced digital controls that provide real-time monitoring and adjustment capabilities. This ensures that the grinding process remains consistent, leading to precise and repeatable results.

3. Robust Construction Built with high-quality materials and designed for durability, these machines can withstand the rigors of continuous operation, making them a long-term investment for any production facility.

4. Ergonomic Design Cincinnati places a strong emphasis on user-friendly design, ensuring that operators can easily set up and maintain the machines. This focus on ergonomics enhances productivity and reduces the risk of operator fatigue.

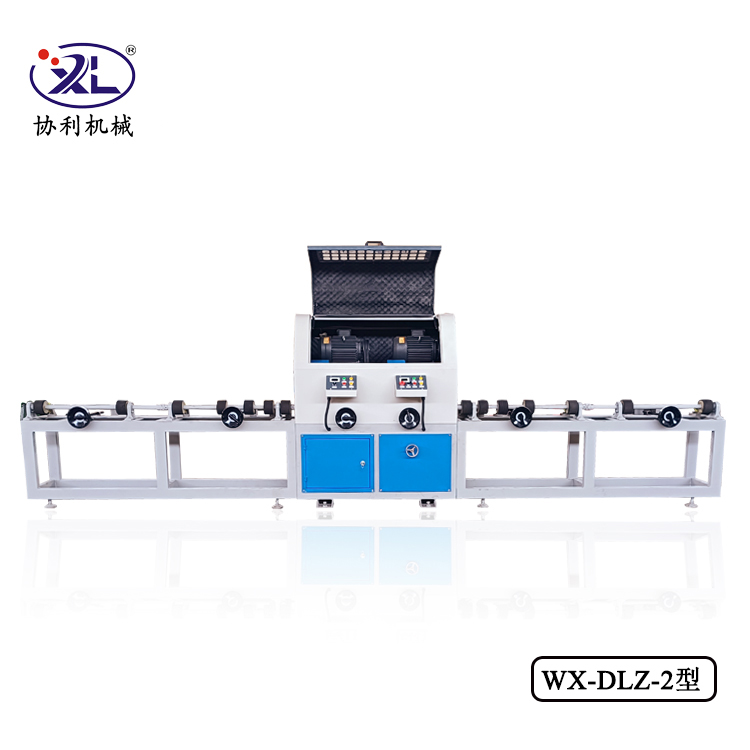

centerless grinder cincinnati products

5. Customization Options The adaptability of Cincinnati centerless grinders allows manufacturers to customize features to better match their specific production requirements. This can include modifications in wheel size, feeding mechanisms, and more.

Advantages of Using Cincinnati Centerless Grinders

Utilizing centerless grinders from Cincinnati Products offers several advantages that enhance production efficiency and quality

- Increased Throughput The uninterrupted processing of parts leads to higher output rates, beneficial for manufacturers aiming to meet large order quantities. - Reduced Production Costs By streamlining the grinding process, Cincinnati grinders help in lowering operational costs associated with labor and time. - Improved Tolerance and Finish The precision associated with centerless grinding ensures that components achieve tight tolerances and superior surface finishes, critical for applications in aerospace, automotive, and other high-tech industries.

- Minimal Setup Time The straightforward design and controls of Cincinnati grinders allow for quick changeovers between different jobs, which is crucial for manufacturers facing fluctuating order volumes.

Applications of Cincinnati Centerless Grinders

The versatility of Cincinnati centerless grinders means they can be employed in a wide array of applications. Some of the most common industries utilizing these machines include

- Automotive For producing precision parts like shafts, gears, and roller bearings. - Aerospace Centerless grinders are essential for manufacturing components that require extreme accuracy and reliability, such as turboshafts and landing gear parts. - Medical Devices The medical industry demands high precision and sterilization capabilities, making Cincinnati grinders well-suited for creating surgical instruments and implants. - Tool and Die In tool manufacturing, achieving specific tolerances is vital, and centerless grinding offers an efficient solution for producing high-quality tools and dies.

Conclusion

Cincinnati Products has carved a niche in the manufacturing industry with its line of centerless grinders, known for their precision, efficiency, and adaptability. As manufacturing demands continue to evolve, investing in such advanced machinery not only enhances production capabilities but also prepares businesses to thrive in an ever-competitive landscape. With the right equipment, manufacturers can achieve exceptional results that meet and exceed industry standards.