Exploring Centerless Grinder Accessories A Supplier's Perspective

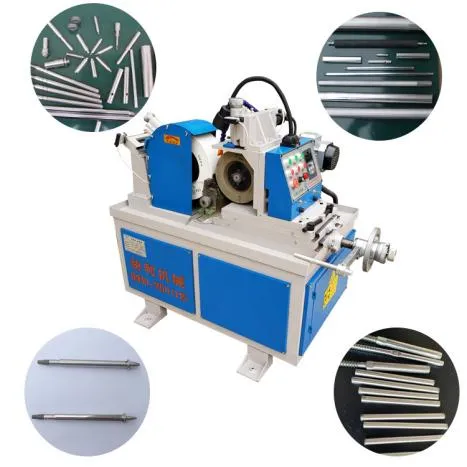

Centerless grinding is a highly efficient machining process that allows for the precise shaping and finishing of cylindrical parts without the need for a center hole. This unique method is widely utilized in various industries, including automotive, aerospace, medical, and manufacturing, due to its high productivity and ability to produce high-tolerance specifications. However, achieving optimal performance from a centerless grinding machine depends significantly on the quality of its accessories. As a supplier of centerless grinder accessories, it is essential to understand the critical components that complement the grinding process.

One of the primary accessories for centerless grinders is the regulating wheel. This wheel controls the speed at which the workpiece is fed into the grinding zone, ensuring a smooth and consistent grinding operation. Regulating wheels come in various materials and hardness levels, which can be customized to suit specific grinding applications. A reliable supplier will offer a range of options to cater to different requirements, allowing manufacturers to achieve the desired finish and tolerances.

Exploring Centerless Grinder Accessories A Supplier's Perspective

Support rollers are also essential accessories for centerless grinders. These rollers assist in maintaining the position and stability of the workpiece during the grinding process. Proper alignment of the workpiece is crucial to prevent vibrations and ensure a consistent finish. A reputable supplier will provide high-quality support rollers designed to withstand the rigors of the grinding environment while offering precision performance.

centerless grinder accessories supplier

Additionally, coolant systems are critical accessories that play a significant role in the longevity of both the workpiece and the grinding machinery. Proper coolant application helps to reduce heat buildup during grinding, preventing burn marks and damage to the workpiece while ensuring the grinding wheel remains in optimal condition. Suppliers should offer a variety of coolant systems, including mist, flood, and through-the-spindle cooling options, to meet diverse operational needs.

In the realm of safety and maintenance, accessories such as wheel dressers and balancing stands are indispensable. Wheel dressers are used to reshape and refresh worn grinding wheels, ensuring they continue to cut efficiently. Balancing stands, on the other hand, help maintain the balance of the grinding wheels, reducing vibrations and extending the lifespan of the machine. A comprehensive supplier will provide these maintenance tools to enhance the performance and durability of centerless grinders.

Finally, specialized accessories such as workpiece holders and fixtures can significantly impact the efficiency of the grinding process. These components are designed to securely hold and align workpieces during grinding, minimizing the risk of defects caused by shifting or misaligning. A reliable supplier should offer a range of custom solutions to meet the specific requirements of various workpiece geometries and dimensions.

In conclusion, the importance of high-quality accessories cannot be overstated in the centerless grinding process. As a supplier, it is crucial to maintain a diverse inventory of products ranging from regulating wheels and grinding wheels to support rollers and coolant systems. By providing manufacturers with the right tools, suppliers can play a vital role in enhancing the efficiency, quality, and overall productivity of centerless grinding operations. With the right accessories, businesses can achieve precision, reliability, and competitiveness in their manufacturing processes.