In the world of precision machining and manufacturing, the centerless grinder plays a pivotal role, offering unmatched efficiency and accuracy. This indispensable tool is renowned for its ability to produce high-quality finishes and tight tolerances, making it an essential piece of equipment for companies focused on high-volume production.

Centerless grinding is a machining process that involves the removal of material from the outside diameter of a workpiece using abrasive cutting. Unlike traditional cylindrical grinding, which involves centering a workpiece between two rotating points, centerless grinding holds the workpiece between a grinding wheel and a regulating wheel. This configuration allows for continuous processing, reducing setup times and enhancing throughput.

One of the primary advantages of the centerless grinder is its increased efficiency. By eliminating the need to center the workpiece, the process can be automated, leading to faster production cycles. This efficiency makes it particularly advantageous in industries where high precision and minimal lead times are critical.

Furthermore, the machine's design allows for the simultaneous grinding of multiple pieces, greatly increasing productivity. This is particularly beneficial in the automotive and aerospace sectors where the demand for high precision components is constant. Parts such as camshafts, crankshafts, and other cylindrical components are produced with exceptional consistency and accuracy using this method.

Professional machinists often attest to the reliability of centerless grinders when it comes to maintaining stringent dimensional tolerances. These machines are equipped with advanced control systems that ensure consistent operation, which is crucial in high-stakes applications where even slight deviations can lead to significant issues.

centerless grinder

However, achieving optimal results with a centerless grinder requires expertise. Operators must have a deep understanding of the interplay between the different wheels, the speed settings, and the material properties of the workpiece. This expertise affects the quality of the finish and the durability of the parts produced. Training and experience are vital to maximizing the potential of this machine, underscoring the importance of skilled labor in the field.

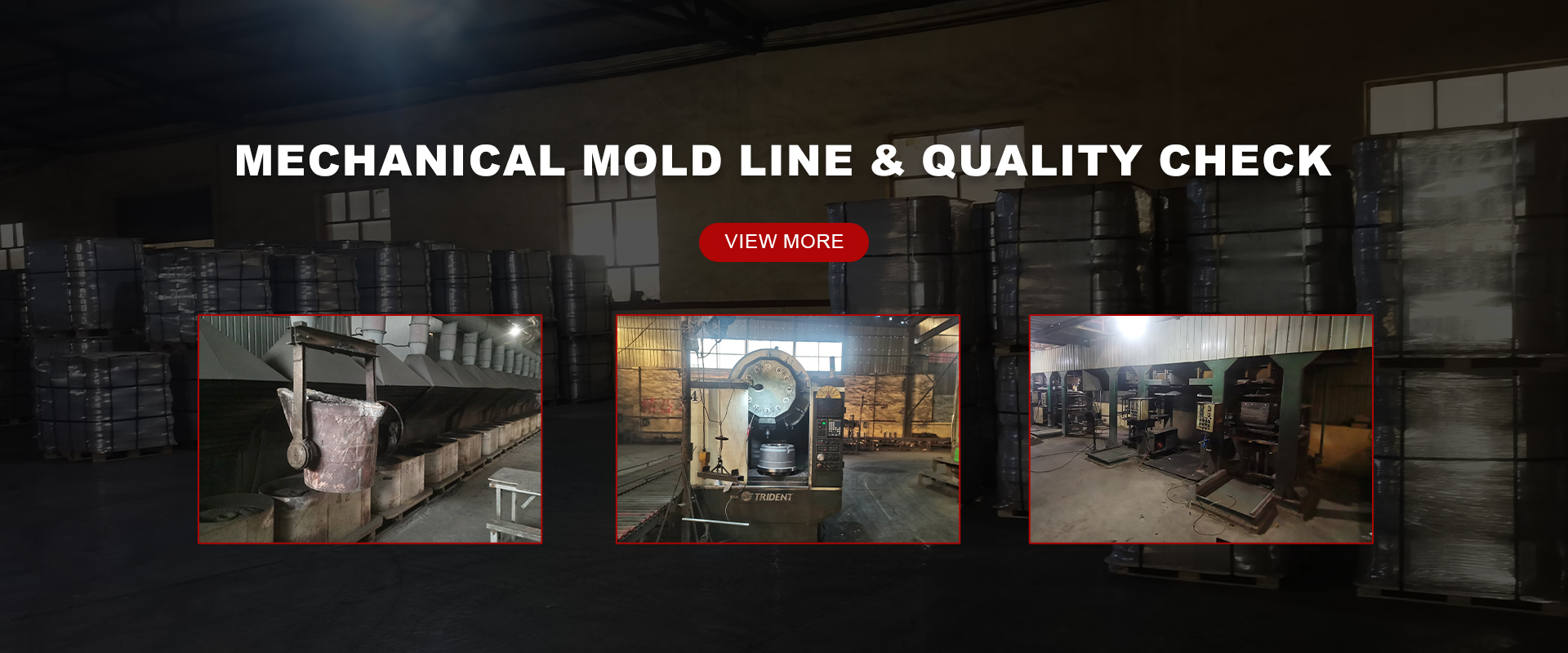

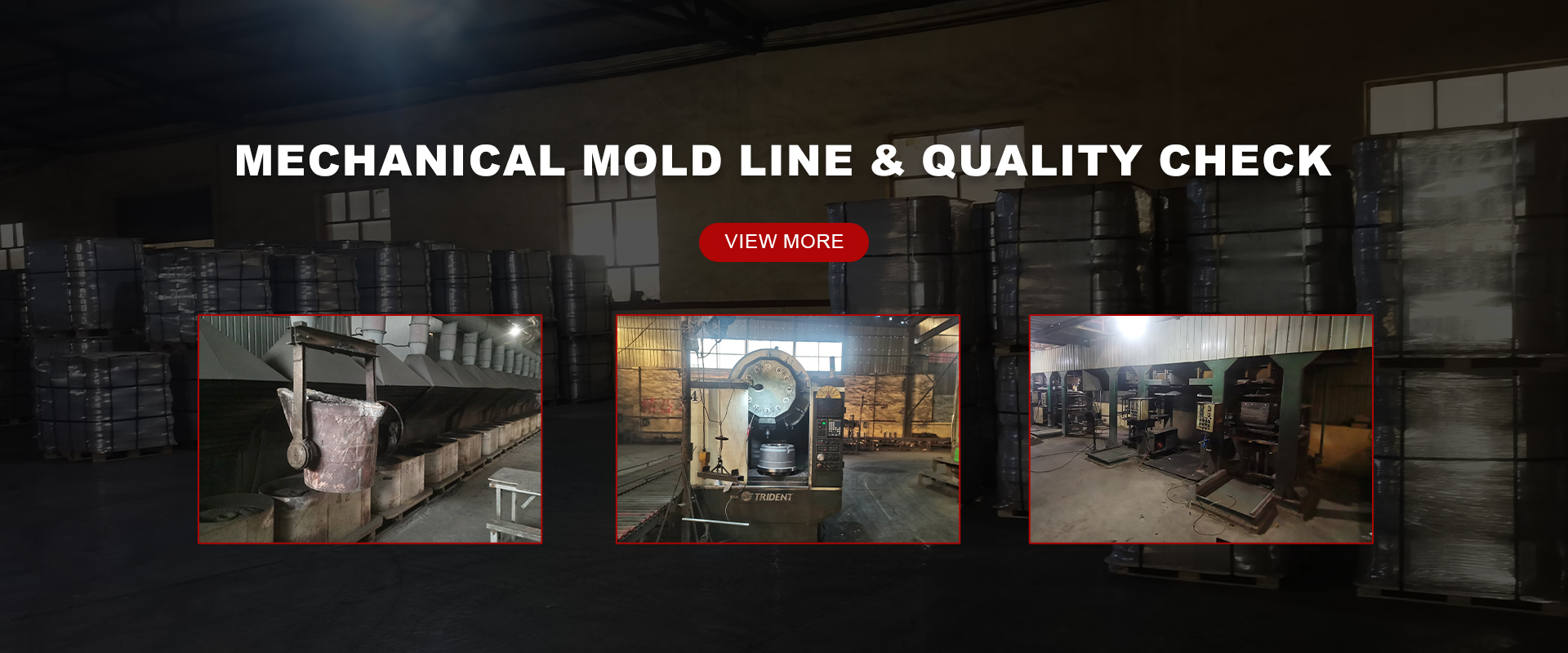

Trustworthiness in centerless grinding is established through rigorous testing and quality control. Manufacturers implement comprehensive inspection protocols to ensure that each component adheres to specified dimensions and surface finishes. This commitment to quality is non-negotiable, particularly in sectors where component failure is not an option.

Finally, the authority of manufacturers and service providers in this niche is backed by years of innovation and customer satisfaction. Leading companies invest significantly in research and development to refine their technology, aiming to improve precision, efficiency, and environmental impact. As a result, they set the standard in the industry, offering advanced solutions that meet the evolving demands of modern manufacturing.

In conclusion, the centerless grinder is more than just a machine; it represents a fusion of technology and expertise that drives manufacturing forward. Companies that leverage this technology realize substantial gains in efficiency and quality, reinforcing their position in competitive markets. Mastery of this process distinguishes industry leaders from followers, making the centerless grinder a cornerstone of modern machining.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.