The Role of Centerless Belt Grinding and Polishing Machines in Modern Manufacturing

In the fast-paced world of modern manufacturing, precision and efficiency are paramount. Among the many tools and technologies that have emerged, centerless belt grinding and polishing machines stand out as essential equipment for achieving high-quality finishes on various metal components. These machines are not only crucial for enhancing the aesthetic appeal of products but also for ensuring their durability and performance. This article delves into the significance of centerless belt grinding and polishing machines, exploring their operation, benefits, and the role of factories in optimizing these technologies.

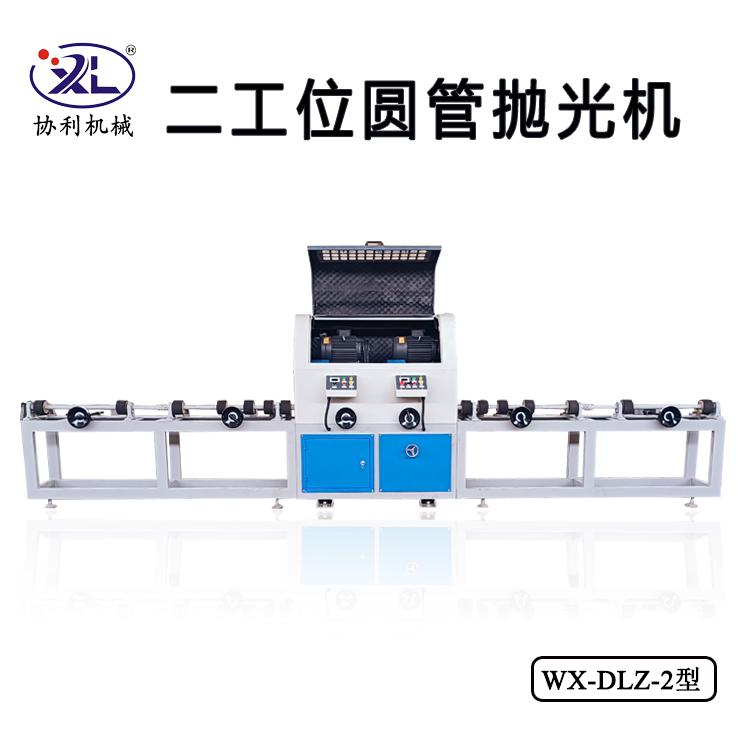

Understanding the Centerless Grinding Process

Centerless grinding is a unique machining process that utilizes abrasive belts to grind and polish materials without the need for a workpiece fixture. This method allows for continuous production, where parts can be fed through the machine without stopping, increasing throughput and efficiency. The design of centerless machines features two wheels the grinding wheel and the regulating wheel. The grinding wheel removes material from the workpiece while the regulating wheel controls the speed and positioning of the part, ensuring consistent results.

One of the key benefits of centerless belt grinding is its ability to handle a wide range of materials, including steel, aluminum, brass, and plastics. This versatility makes it a suitable choice for various industries, from automotive and aerospace to medical devices and consumer products. The abrasive belts can be customized to achieve different finishes, from coarse grinding to fine polishing, catering to the specific needs of each application.

The Advantages of Centerless Belt Grinding Machines

1. Improved Efficiency Traditional grinding methods often require multiple setups and manual interventions. Centerless belt grinding machines streamline the process, allowing manufacturers to achieve smoother surfaces in less time.

2. Consistent Quality These machines produce exact and repeatable results, minimizing the risk of defects. With precise control over the grinding process, manufacturers can maintain stringent tolerances and ensure high-quality outputs.

3. Reduced Labor Costs Automation in centerless grinding reduces the reliance on skilled labor. Once set up, these machines can operate continuously, decreasing the manpower needed for production.

4. Adaptability Many centerless grinding machines are equipped with programmable features, allowing for easy adjustment to different workpiece sizes and shapes. Manufacturers can quickly switch between products, maximizing utilization and flexibility.

centerless belt grinding polishing machine factories

5. Enhanced Safety Automation reduces manual handling of sharp components, minimizing the risk of accidents in the workplace. Additionally, modern machines come with safety guards and features that promote a safer working environment.

Factories Embracing Centerless Belt Grinding Technologies

To harness the full potential of centerless belt grinding and polishing machines, factories are investing in advanced technologies and production methodologies. Incorporating these machines into the production line requires a strategic approach to design and layout, ensuring optimal workflow and minimal waste.

1. Integration with Other Processes Many factories are integrating centerless grinding with other operations, such as laser cutting and CNC machining. This synergy allows for a streamlined production process, reducing lead times and enhancing overall efficiency.

2. Regular Maintenance and Upgrades To maintain performance, factories invest in regular maintenance schedules and upgrades for their grinding machines. Staying current with technological advancements ensures that production remains competitive and that machines operate at peak efficiency.

3. Training and Development As technology evolves, so does the skill set required to operate these machines. Factories are increasingly focusing on training programs that familiarize operators with the latest features and best practices, enhancing productivity and safety.

4. Sustainability Practices With an increasing emphasis on sustainability in manufacturing, factories are exploring eco-friendly grinding solutions. This includes using biodegradable coolants and optimizing energy consumption during the grinding process.

Conclusion

In conclusion, centerless belt grinding and polishing machines play a pivotal role in modern manufacturing, offering unparalleled efficiency, consistency, and flexibility. As factories continue to evolve and embrace these technologies, they not only enhance their production capabilities but also contribute to the overall advancement of the manufacturing sector. With the ongoing demand for high-quality products across various industries, the significance of centerless grinding machines is likely to grow, solidifying their place as indispensable tools in the quest for excellence in manufacturing.