Centerless Belt Grinding and Polishing Machine Revolutionizing Metal Finishing

The centerless belt grinding and polishing machine has emerged as a game changer in the manufacturing and metal finishing industry

. This innovative technology enhances the efficiency and precision of grinding and polishing processes, significantly improving product quality and manufacturing output.At its core, the centerless design allows for continuous processing of workpieces without needing to maintain a fixed center point. This capability enables the machine to handle various shapes and sizes of metal components, making it versatile for different applications. The absence of traditional workpiece holding fixtures not only streamlines the workflow but also minimizes setup times, allowing manufacturers to switch between tasks rapidly.

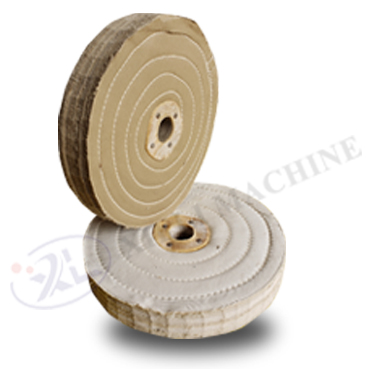

One of the primary advantages of a centerless belt grinding and polishing machine is its ability to deliver consistent surface finishes. The machine utilizes abrasive belts that can be tailored to achieve specific finishing requirements, whether it’s a high polish or a smooth matte surface. This adaptability makes it an ideal choice for industries such as automotive, aerospace, and medical device manufacturing, where precision and quality are critical.

centerless belt grinding polishing machine

The operation of this machine is straightforward yet effective. The workpiece is fed through a small gap between the grinding wheel and a regulating wheel, allowing for a seamless process. The continuous motion ensures that each part receives an even grind, eliminating the risk of uneven wear or damage that could occur in other grinding methods.

Moreover, centerless grinding and polishing machines are designed with user-friendly interfaces, allowing operators to easily adjust settings such as speed and pressure. This feature reduces the likelihood of user error and enhances safety. Additionally, many modern machines are equipped with advanced automation technology, including robotic arms for loading and unloading workpieces. This further streamlines operations and reduces labor costs.

Environmental considerations have also been addressed in the design of these machines. The use of coolant and efficient dust collection systems ensures that waste is minimized, making it a more sustainable choice for manufacturers. As industries aim to lower their carbon footprints, investing in such technologies provides a path toward greener practices.

In conclusion, the centerless belt grinding and polishing machine represents a significant advancement in metal finishing technology. With its efficiency, versatility, and ability to produce high-quality finishes, it is poised to play a crucial role in the future of manufacturing, helping businesses meet ever-increasing demands for precision and quality. As industries continue to evolve, the adoption of such innovative machinery will undoubtedly enhance productivity and sustainability in the metalworking sector.