The field of surface finishing has seen revolutionary advancements, with the centerless belt grinding polishing machine emerging as a game changer for industries requiring high-precision surface finishing. This machine is not merely a tool but a technological marvel that epitomizes a blend of engineering excellence and practical application, enhancing both productivity and quality of output.

Understanding the Centerless Belt Grinding Polishing Machine

Centerless belt grinding polishing machines streamline the finishing process by eliminating the need for workpiece fixtures. This mechanism significantly reduces preparation time and overall labor costs, contributing to a more efficient production line. The machine’s centerless design allows it to handle cylindrical workpieces with varying diameters seamlessly, maintaining superior consistency and precision across all operations.

Experience with Centerless Technology

In industrial settings where speed and precision are paramount, the centerless belt grinding polishing machine excels by reducing cycle times without compromising on quality. Users commonly cite its ability to produce finishes that meet stringent industry standards as a primary advantage. Its ability to process large batches with uniform results ensures that even the most demanding production schedules are met with ease.

Extensive real-world applications in sectors such as automotive, aerospace, and metal fabrication underscore the machine’s versatility. Operators have consistently reported its ability to reduce material waste and achieve finishes that would otherwise require multiple machine interventions, thereby enhancing overall operational efficiency.

Expertise in Engineering and Design

The engineering behind the centerless belt grinding polishing machine is a testament to its specialized design.

It utilizes precision abrasive belts and automation controls that cater to both rough grinding and fine polishing tasks. Experts in mechanical engineering will appreciate the robust construction of these machines, allowing them to withstand high operational demands and maintain structural integrity over prolonged periods.

What sets these machines apart is the customization ability, wherein specific machine parameters can be adjusted to fit unique project requirements. This adaptability, combined with a user-friendly interface, ensures operators with varying levels of expertise can achieve professional-grade outcomes with minimal training.

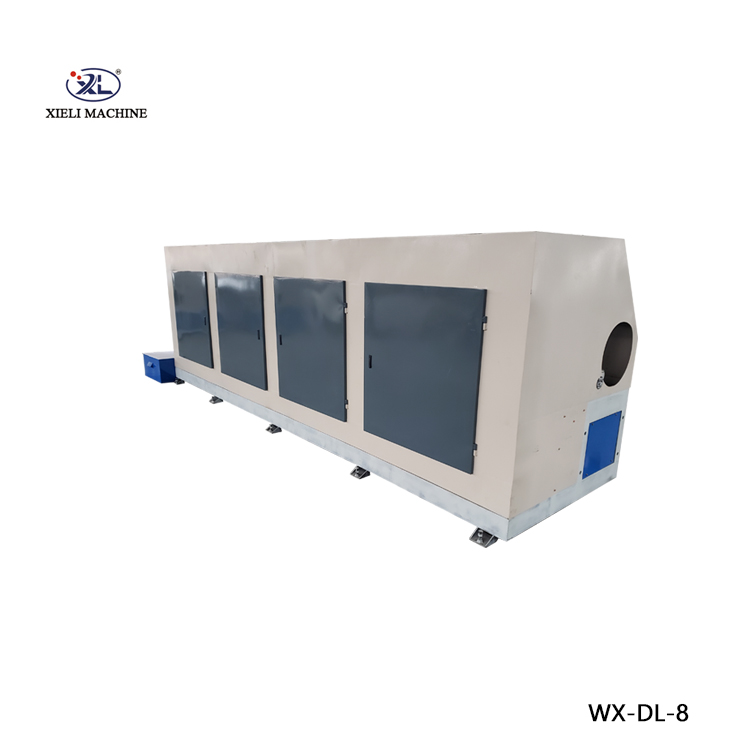

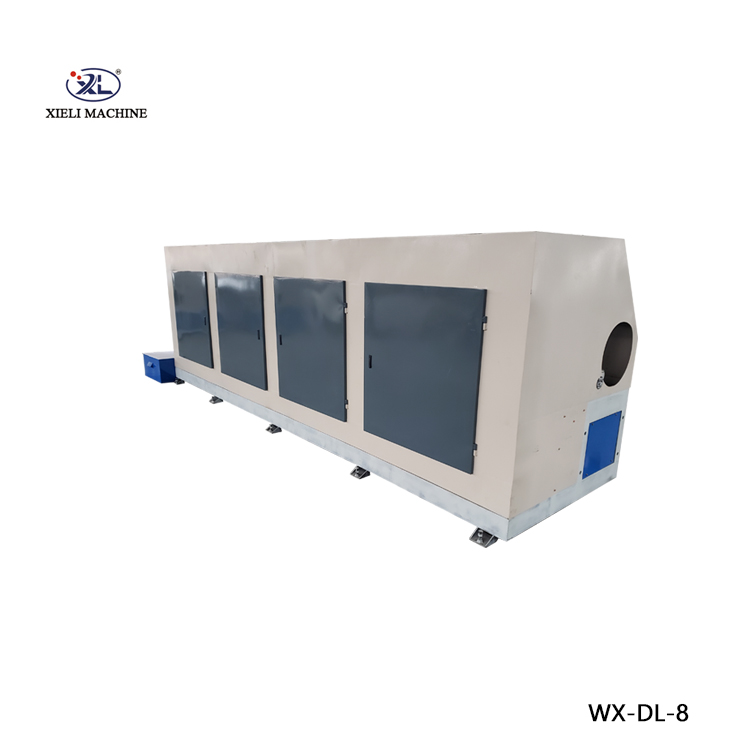

centerless belt grinding polishing machine

Authoritativeness in Surface Finishing

Endorsements from standards organizations and compliance with international quality benchmarks cement the centerless belt grinding polishing machine’s status as an authoritative fixture in manufacturing. Certifications from authoritative bodies highlight its contribution to safety and efficiency in industrial environments, reinforcing its role as a cornerstone in surface finishing technology.

Industry leaders and technologists contribute to ongoing enhancements of this machine type, focusing on integrating smart technologies that provide real-time feedback and diagnostics. This push towards Industry 4.0-ready equipment demonstrates its ongoing evolution and adaptability to future manufacturing needs.

Trustworthiness in Operation and Maintenance

One of the key factors that build trust with users is the machine’s reliability and ease of maintenance. Routine maintenance procedures are simplified thanks to the machine’s design, with easily accessible components that require minimal downtime for service and repair. Users have consistently reported long service lives and sustained performance, reducing the total cost of ownership.

Moreover, manufacturers offer comprehensive support systems, from initial setup assistance to ongoing technical support, ensuring users can rely on the machine’s performance. This robust support network enhances trust, assuring operators that they have the necessary resources and backing to maximize their machine’s potential.

Conclusion

The centerless belt grinding polishing machine stands as a paragon of modern engineering, offering unparalleled efficiency, versatility, and precision in surface finishing applications. Its adoption across industry sectors speaks volumes of its capability to elevate manufacturing processes, proving it to be an indispensable asset for any operation demanding high-quality surface treatment. With advancements continually being integrated, it remains at the forefront of technological innovation, ensuring it meets the ever-evolving needs of global industry standards.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.