Centerless Belt Grinder Exporters Shaping the Future of Precision Grinding

In the world of manufacturing and metalworking, precision is paramount. One key piece of machinery that plays a crucial role in achieving exact specifications in various applications is the centerless belt grinder. As the global market for these machines continues to evolve, centerless belt grinder exporters have positioned themselves as vital players, not only supplying machinery but also shaping the industry's future through innovation and efficiency.

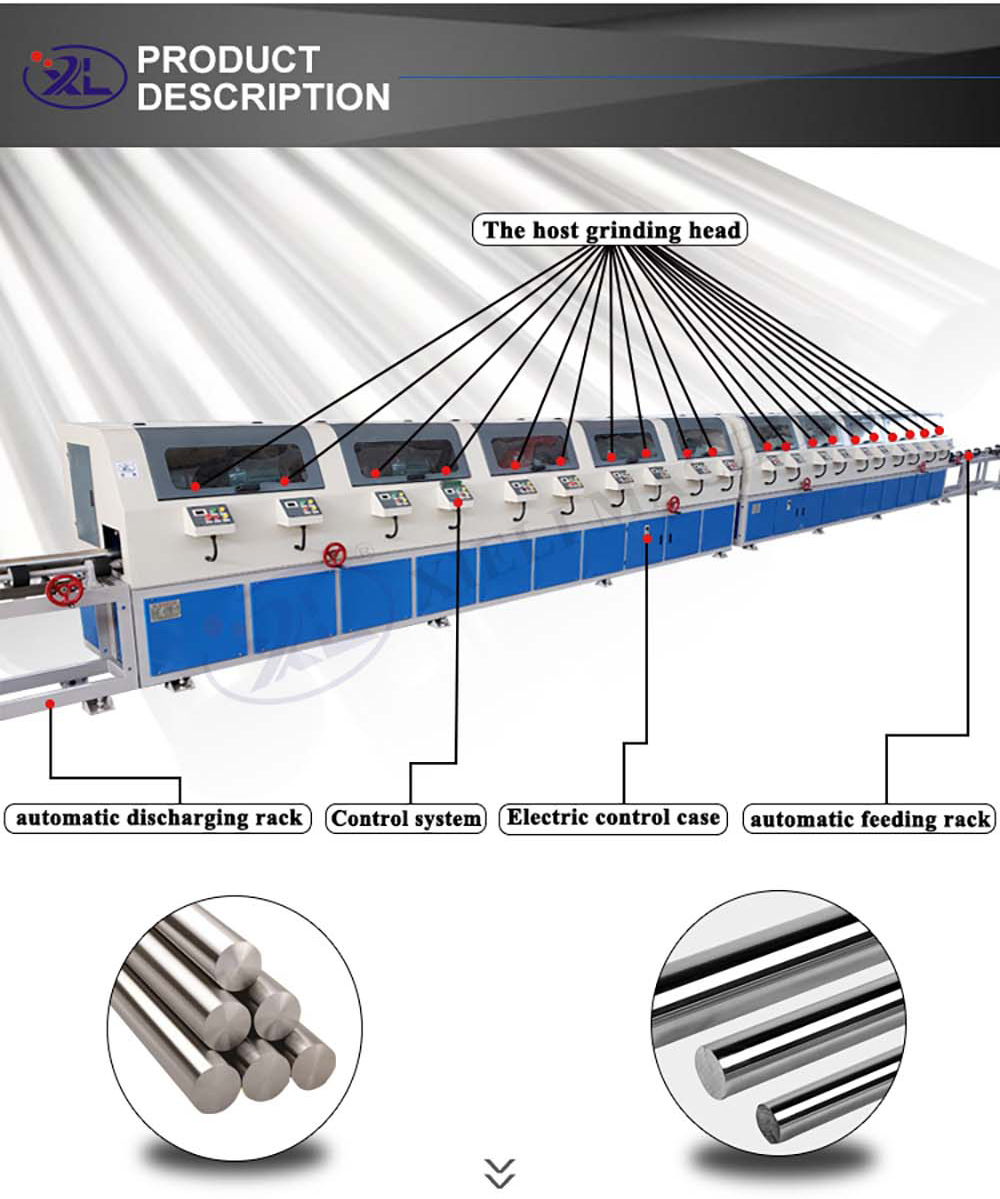

Understanding Centerless Belt Grinders

Centerless belt grinders are specialized machines used for grinding cylindrical workpieces. Unlike traditional grinding methods that rely on centers or fixtures to hold the workpiece, centerless grinding allows for the uninterrupted processing of materials. This method provides efficient material removal while achieving high precision and superior surface finishes.

These grinders utilize a combination of abrasive belts and grinding wheels to perform tasks such as removing material, deburring, and polishing. The significant advantage of centerless grinding is its ability to handle multiple pieces simultaneously, which dramatically increases productivity in manufacturing operations.

The Role of Exporters

As the demand for high-quality precision grinding machines rises globally, exporters of centerless belt grinders have become critical in meeting this demand

. These exporters not only provide machinery but also offer a suite of services, including installation, training, and ongoing support to ensure the machines operate effectively.Exporters are often tasked with navigating complex international regulations and standards. They must ensure that their machines meet the specific requirements of different markets, which can vary significantly from one region to another. This adaptability is vital for success in the competitive global landscape.

Trends in the Export Market

centerless belt grinder exporters

The export market for centerless belt grinders is influenced by several trends. One notable trend is the growing emphasis on automation and smart manufacturing. As industries adopt Industry 4.0 principles, including the Internet of Things (IoT) and artificial intelligence (AI), there is an increasing demand for machines that can integrate with digital systems. Exporters that can supply advanced, interconnected grinding solutions are likely to gain a competitive edge.

Moreover, sustainability has become a focal point for manufacturers worldwide. Centerless belt grinder exporters are responding by developing energy-efficient machines that minimize waste and reduce the environmental impact of the manufacturing process. This commitment to sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Challenges Faced by Exporters

While opportunities abound, centerless belt grinder exporters also face challenges in the global market. Economic fluctuations, trade tariffs, and geopolitical tensions can significantly impact export activities. Additionally, maintaining quality control and ensuring consistent supply chains amidst these economic uncertainties requires strategic planning and robust management practices.

Another challenge is the need for continuous innovation. As technology rapidly evolves, exporters must invest in research and development to improve their product offerings. This includes staying ahead of trends and aligning with customer needs, which can be resource-intensive but is critical for long-term success.

The Future Outlook

Looking ahead, the centerless belt grinder export market is expected to experience robust growth as industries continue to embrace precision engineering and advanced manufacturing technologies. With the rise of new markets, particularly in developing economies, exporters have the opportunity to expand their reach and establish new partnerships.

Investments in technology will play a pivotal role in this growth. Exporters that embrace cutting-edge advancements, such as automation, data analytics, and sustainable practices, will likely lead the way in setting new industry standards.

In conclusion, centerless belt grinder exporters are more than just vendors; they are key enablers of innovation and efficiency in the metalworking sector. As they navigate challenges and seize opportunities, they will undoubtedly shape the future of precision grinding, ensuring that manufacturers can meet the ever-growing demands of a competitive landscape. By focusing on quality, adaptability, and technological advancement, these exporters will remain at the forefront of the industry, contributing to the continued evolution of manufacturing processes worldwide.