Centerless Valve Grinders for Sale A Comprehensive Guide for Suppliers

In the world of precision machining, centerless valve grinders play a crucial role. These sophisticated machines are designed to optimize the grinding process, enabling manufacturers to produce high-quality valves at competitive rates. As the demand for efficient valve production continues to rise across various industries, there has been an increasing interest in centerless valve grinders for sale. This article aims to provide a comprehensive overview of these machines, the suppliers who offer them, and key considerations for potential buyers.

Understanding Centerless Grinding

Centerless grinding is a method that allows for the production of cylindrical parts without the need for the workpiece to be fixed in place. Unlike traditional grinding methods, where the piece is held between two centers, centerless grinding uses a different set-up. The workpiece is supported by a combination of a grinding wheel, a regulating wheel, and a work rest blade. This enables high production rates with excellent dimensional accuracy, which is essential for the manufacturing of valves used in various applications, including automotive, aerospace, and industrial machinery.

Advantages of Centerless Valve Grinders

One of the most significant advantages of centerless valve grinders is their ability to handle multiple components without the need for complex setups. They are particularly beneficial for manufacturers who require consistency and efficiency in production. The centerless grinding process offers several benefits

1. Increased Efficiency The continuous feeding mechanism allows for high throughput, reducing production times significantly. 2. Precision Centerless grinding machines can achieve tight tolerances and excellent surface finishes, crucial for valve components that must withstand pressure and wear. 3. Flexibility These grinders can accommodate various sizes and shapes of valves, making them versatile for different manufacturing needs.

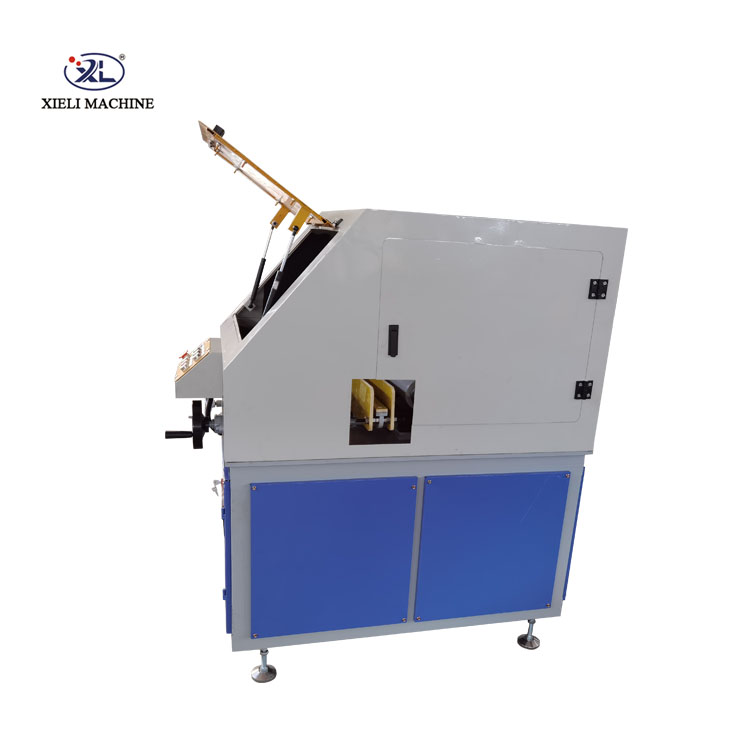

centerless valve grinder for sale suppliers

Finding Reliable Suppliers

As the market for centerless valve grinders grows, numerous suppliers have emerged, each offering various models and technologies. When searching for a reliable supplier, potential buyers should consider the following factors

1. Reputation Researching feedback and reviews from previous clients can provide insight into a supplier's reliability and the quality of their machines. 2. Quality of Machines It is essential to evaluate the specifications and capabilities of the grinders offered. Look for machines with advanced features such as automatic feeding, programmable controls, and robust build quality. 3. After-Sales Support Suppliers that offer strong after-sales support, including readily available spare parts and skilled technicians for maintenance, are invaluable for minimizing downtime. 4. Customization Options Depending on specific manufacturing needs, buyers may require customization. Suppliers that offer flexible solutions can better serve diverse requirements.

Conclusion

Centerless valve grinders represent a critical investment for manufacturers focused on precision and efficiency. With the growing market for these machines, suppliers offer various options that cater to different needs and budgets. By understanding the benefits of centerless grinding and considering key supplier attributes, manufacturers can make informed purchasing decisions that will enhance their production capabilities.

As industries evolve, maintaining a competitive edge hinges on the quality and reliability of manufacturing equipment. Investing in a centerless valve grinder may well be the step toward achieving operational excellence. Thus, exploring the options available in the market will empower businesses to optimize their valve production processes, ultimately leading to improved profitability and success in their respective fields.