The Rise of ODM Centerless Grinder Suppliers

In the world of manufacturing, precision and efficiency are paramount. The demand for high-quality machinery that can deliver outstanding results has led to the emergence of Original Design Manufacturer (ODM) centerless grinders. These specialized suppliers are reshaping the landscape of machining by providing innovative solutions tailored to customer needs.

Understanding Centerless Grinding

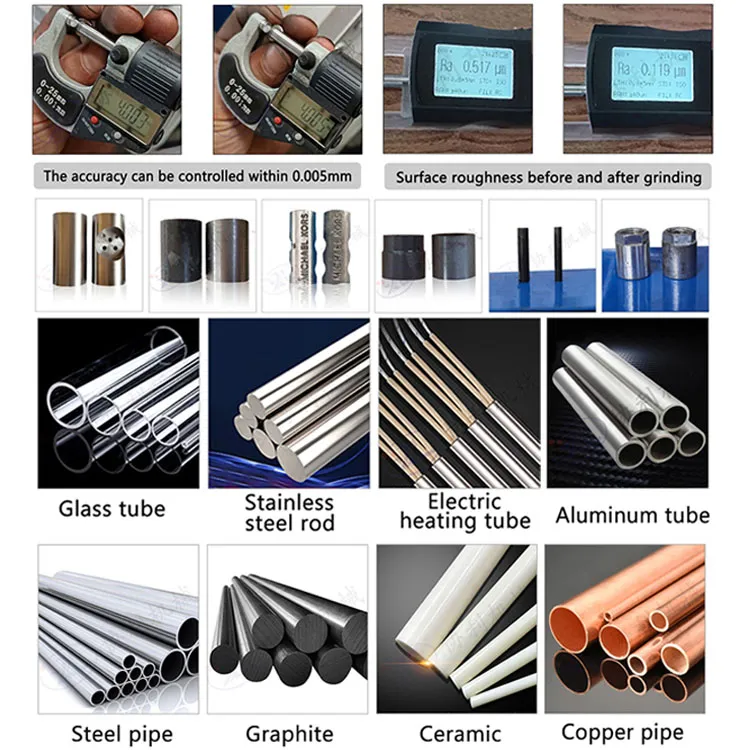

Centerless grinding is a machining process that produces cylindrical parts without the need for pre-existing holes. The process involves three key components the grinding wheel, the regulating wheel, and the workpiece. The workpiece is held between these two wheels, and as the grinding wheel rotates, it removes material from the workpiece, achieving precise dimensions, tight tolerances, and excellent surface finishes. This method is widely used in industries ranging from automotive to aerospace, where precision is critical.

The Role of ODM Suppliers

ODM suppliers play a vital role in the manufacturing ecosystem by designing and producing centerless grinders according to client specifications. This means that they not only supply the machines but also contribute to their design, ensuring that the final product meets specific operational requirements. By collaborating closely with customers, ODM suppliers can offer tailored solutions that enhance productivity and performance.

One of the key advantages of working with ODM centerless grinder suppliers is the ability to create bespoke machinery that addresses unique challenges. For instance, a company that specializes in high-precision components may require a grinder that operates at specific speeds or integrates advanced features such as automated loading and unloading systems. ODM suppliers can develop grinders with custom specifications, allowing manufacturers to optimize their production processes and stay competitive in the market.

Quality and Innovation

odm centerless grinder suppliers

Quality assurance is another critical aspect of ODM centerless grinder suppliers. These companies typically adhere to stringent quality control measures throughout the manufacturing process. From selecting raw materials to testing the final product, every step is scrutinized to ensure that the machines meet industry standards. This commitment to quality not only boosts the performance of the machines but also enhances the reputation of the suppliers themselves.

Additionally, ODM suppliers are often at the forefront of innovation in machine design and manufacturing technologies. They continuously invest in research and development to improve existing products and create new solutions that meet the evolving demands of the industry. This dedication to innovation allows them to incorporate the latest advancements, such as smart technology and automation, into their equipment, providing manufacturers with cutting-edge tools that enhance efficiency and productivity.

Global Reach and Support

The rise of ODM centerless grinder suppliers has also been facilitated by globalization. With the internet breaking down geographical barriers, manufacturers can now source specialized machinery from suppliers around the world. This global reach not only provides access to a wider range of technologies but also facilitates competitive pricing, as suppliers can leverage different manufacturing environments.

Moreover, most ODM suppliers offer comprehensive after-sales support, including maintenance, spare parts, and training programs. This level of support is essential for manufacturers to ensure the longevity and optimal performance of their machines, making ODM suppliers valuable partners in the production process.

Conclusion

As industries continue to evolve and demand for precision machinery grows, ODM centerless grinder suppliers stand out as key players in the market. Their ability to create customized solutions, commitment to quality, and focus on innovation drive efficiency and competitiveness for manufacturers. As businesses seek to harness the full potential of their operations, the partnership with ODM suppliers will undoubtedly play a crucial role in achieving success in today's dynamic manufacturing landscape.