Understanding Centerless Grinder Operator Suppliers

Centerless grinding is a precision machining process that is widely used in manufacturing industries for producing cylindrical parts with high accuracy and excellent surface finishes. It requires specific equipment and skilled operators to ensure consistent quality and efficiency in production. As a result, identifying reliable centerless grinder operator suppliers is crucial for businesses looking to enhance their manufacturing processes.

What is Centerless Grinding?

Centerless grinding is a unique type of grinding technique that allows the workpiece to be held between two wheels, namely a grinding wheel and a regulating wheel. Unlike traditional grinding, where the workpiece is held by a chuck or fixture, centerless grinding offers the advantage of continuous production without the need for complex setups. This method is particularly advantageous for long and cylindrical parts that need to be produced in large quantities.

Why Choose a Reliable Supplier?

The role of a skilled centerless grinder operator cannot be overstated. Operators must possess a deep understanding of machining principles, be adept at troubleshooting issues, and be capable of monitoring production quality. This requires ongoing training and the use of high-quality equipment. Thus, partnering with a reputable supplier who provides trained operators and reliable machinery can significantly impact a company's productivity and product quality.

What to Look for in Suppliers?

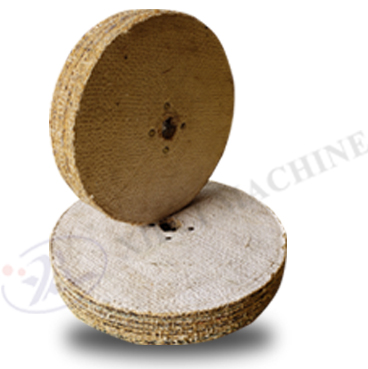

centerless grinder operator suppliers

When seeking centerless grinder operator suppliers, manufacturers should consider several factors. Firstly, the supplier’s reputation within the industry is crucial. Established suppliers with a history of delivering quality products and services often provide added assurance. Additionally, suppliers should offer comprehensive training programs, ensuring that their operators are well-equipped to handle the machinery and understand the intricacies of the grinding process.

Moreover, suppliers should also be able to provide after-sales support, including maintenance services and access to spare parts. This support is essential for minimizing downtime and maintaining the efficiency of the grinding operations.

Emphasizing Technology and Innovation

In today’s fast-paced manufacturing environment, technology integration is key. Suppliers that embrace advanced technology, such as automation and real-time monitoring systems, can significantly enhance the performance of centerless grinding operations. These innovations not only improve precision but also streamline production processes, ultimately boosting profitability.

Conclusion

In conclusion, the selection of a supplier for centerless grinder operators is a critical decision that can greatly influence a manufacturing company’s success. By focusing on supplier reputation, operator training, support services, and technological advancements, businesses can ensure they are well-equipped to meet the demands of their production goals. Investing in skilled operators and reliable machinery will ultimately lead to improved product quality and operational efficiency.