Filmatic for Centerless Grinder Machine Suppliers

In the rapidly advancing world of manufacturing and machining, the role of specialized equipment cannot be overstated. One such pivotal piece of machinery is the centerless grinder. This machine facilitates high-precision grinding for a variety of materials, ensuring tight tolerances and exceptional surface finishes. As the demand for such machines increases, Filmatic has established itself as a reputable supplier for centerless grinder machines, providing tools that meet the rigorous standards of modern industries.

Understanding Centerless Grinding

Centerless grinding is a form of cylindrical grinding where the workpiece is not located between two centers, but instead is supported by a work blade and rotated by a regulating wheel. This innovative setup eliminates the need for complex setups that are common in traditional grinding processes. The advantages of centerless grinding include higher throughput, increased efficiency, and the ability to grind multiple parts simultaneously, making it ideal for mass production environments.

Why Choose Filmatic?

When it comes to sourcing centerless grinder machines, Filmatic has carved out a niche as a trusted supplier in the global marketplace. Their extensive product line features machines that boast cutting-edge technology, enabling manufacturers to achieve greater precision and enhanced productivity.

Quality and Innovation

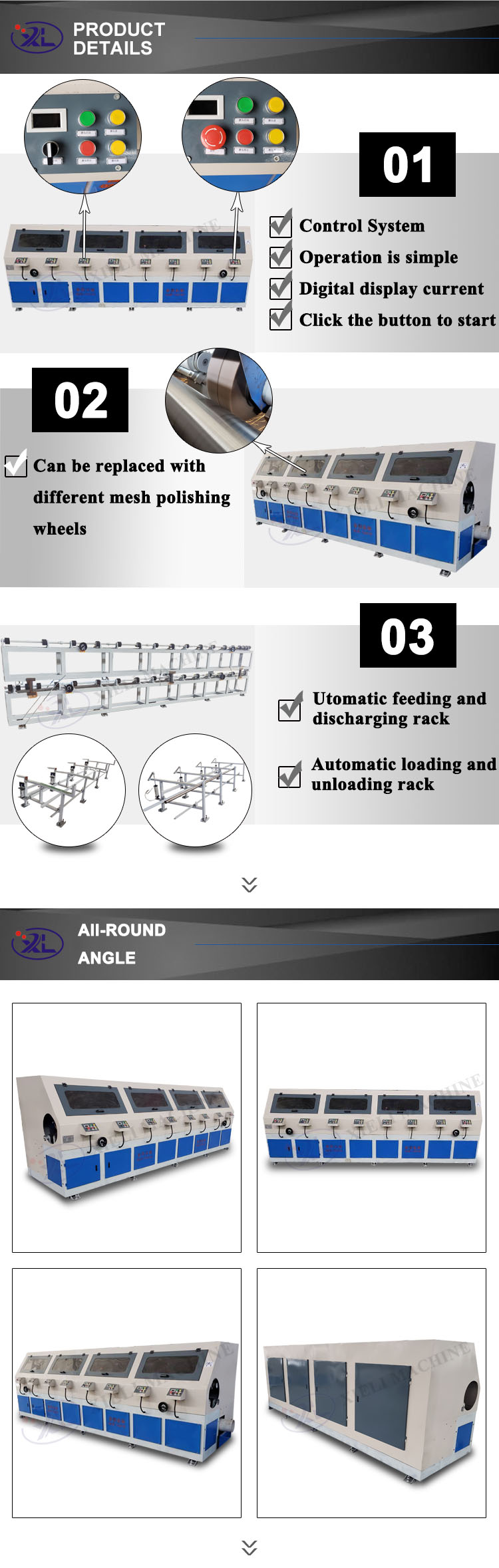

Filmatic prioritizes quality in its manufacturing processes. Each machine is designed and built to withstand the rigors of industrial applications while providing consistent performance. Utilizing state-of-the-art technology, Filmatic ensures that its machines incorporate modern features such as automated controls, advanced safety mechanisms, and energy-efficient designs, which all contribute to reduced operating costs and improved output.

filmatic for centerless grinder machine suppliers

Moreover, innovation is at the heart of what Filmatic does. The team consistently invests in research and development to stay ahead of industry trends. This proactive approach allows them to introduce new features that cater to the evolving needs of their clients. For instance, with the rise of smart manufacturing, Filmatic is integrating IoT applications into their machines, enabling real-time monitoring and data analytics to further enhance productivity.

Customer-Centric Approach

One of Filmatic’s core strengths lies in its customer-centric approach. They understand that each client has unique needs and challenges. As such, the company provides tailored solutions that cater to specific requirements. From custom machine configurations to personalized maintenance plans, Filmatic ensures that clients receive not only top-notch equipment but also unparalleled support.

Additionally, their team of experienced engineers and technicians are always available for consultation, offering expert advice on machine selection and maintenance. This level of support not only instills confidence in customers but also fosters long-term relationships built on trust and reliability.

Global Reach and Local Support

Filmatic has successfully established a global presence, serving clients across various sectors, including automotive, aerospace, medical devices, and more. Despite their international footprint, they maintain a commitment to local support. Their network of service centers and trained professionals ensure that customers can access timely assistance, minimizing downtime and optimizing production efficiency.

Conclusion

Filmatic’s expertise in the realm of centerless grinder machines positions it as a go-to supplier for companies aiming to enhance their machining capabilities. With a firm commitment to quality, innovation, and customer service, Filmatic stands out in a competitive marketplace. As industries continue to evolve, partnering with a reliable supplier like Filmatic not only serves immediate needs but also paves the way for long-term success in the manufacturing landscape.