The Evolution and Importance of CNC Centerless Grinder Machine Manufacturers

In the modern manufacturing landscape, precision and efficiency are paramount, particularly in industries that require fine tolerances and high production rates. One of the integral machines that cater to these demands is the CNC (Computer Numerical Control) centerless grinder. As the industry continues to evolve, the role of CNC centerless grinder machine manufacturers becomes increasingly critical in ensuring that businesses have access to the latest technology for optimal performance.

Understanding Centerless Grinding

Centerless grinding is a machining process that involves removing material from the outer diameter of a workpiece. Unlike traditional grinding techniques that require the workpiece to be held between centers, centerless grinding allows for continuous operation. It utilizes two wheels — a grinding wheel and a regulating wheel. The grinding wheel removes material from the workpiece, while the regulating wheel controls the speed and position of the workpiece. This method is particularly beneficial for producing high volumes of cylindrical parts with precision.

The Role of CNC Technology

The introduction of CNC technology to centerless grinding has revolutionized the manufacturing process. CNC systems offer unparalleled accuracy and repeatability, allowing manufacturers to produce complex parts with exact specifications. Operators can program the machines to perform a variety of tasks, such as adjusting speeds and feed rates, thus reducing the risk of human error and increasing productivity.

Furthermore, CNC centerless grinders are equipped with advanced software that enables real-time monitoring and adjustments. This capability ensures that deviations in dimensions can be corrected on-the-fly, significantly reducing scrap rates and enhancing overall efficiency. As a result, businesses can achieve tighter tolerances and higher quality finishes, which are crucial in industries such as automotive, aerospace, and medical device manufacturing.

The Importance of Choosing the Right Manufacturer

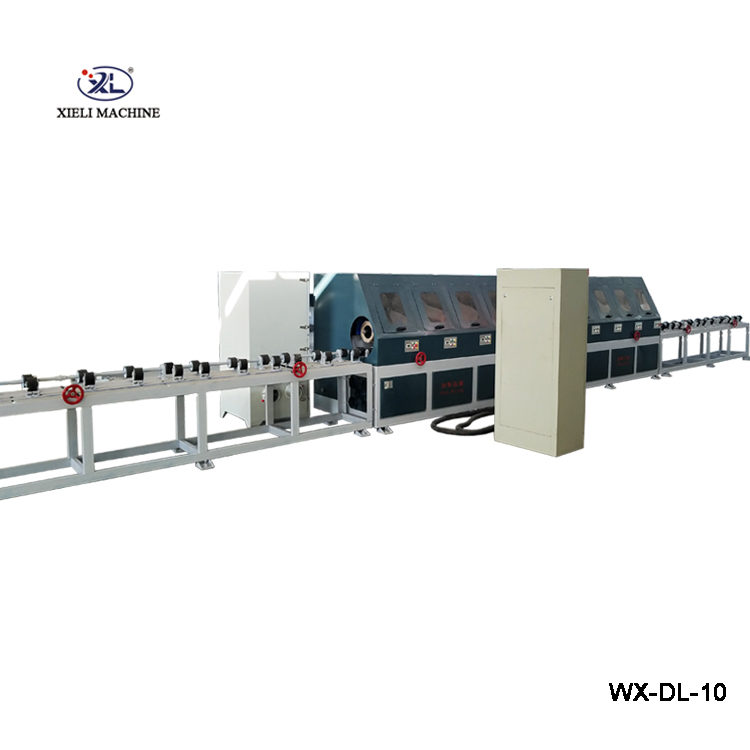

cnc centerless grinder machine manufacturer

Selecting a reliable CNC centerless grinder machine manufacturer is a crucial decision for any business looking to enhance its production capabilities. The manufacturer’s experience, technology, and customer support greatly influence the operation and maintenance of the machines.

Leading manufacturers are continually investing in research and development to innovate and improve their machines. They incorporate the latest materials and technologies, ensuring that their machines are not only efficient but also durable. Moreover, reputable manufacturers offer comprehensive customer support, including training programs, maintenance services, and prompt technical assistance. This support can be invaluable, particularly for businesses that are new to CNC machining or those looking to upgrade their existing systems.

Trends in Centerless Grinding Technology

The landscape of CNC centerless grinding is constantly changing, with various trends shaping the future of this technology. One significant trend is the movement towards automation. Many manufacturers are integrating robotic systems with their centerless grinders to facilitate loading and unloading processes. This integration not only boosts productivity but also minimizes labor costs and enhances workplace safety.

Another notable trend is the use of IoT (Internet of Things) technology. By connecting grinding machines to the internet, manufacturers can gather data in real-time, allowing for predictive maintenance and more informed decision-making. This connectivity aligns with the larger trend of Industry 4.0, where smart factories utilize interconnected devices to improve operations.

Conclusion

CNC centerless grinder machine manufacturers play a vital role in advancing the manufacturing industry. Their ability to provide efficient, precise, and reliable grinding solutions is essential for businesses that demand high-quality components. As technology continues to evolve, manufacturers who adapt and innovate will lead the way in shaping the future of centerless grinding. By investing in state-of-the-art machines and ongoing customer support, they ensure that their clients remain competitive in an ever-changing market.