Centerless Cylindrical Grinding Machine Factories An Overview

Centerless cylindrical grinding is a precision machining process widely utilized in manufacturing to produce high-precision cylindrical parts. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding allows for efficiency and consistency, essential in industries like automotive, aerospace, and medical device manufacturing. In this article, we will explore the significance of centerless cylindrical grinding machine factories, their operations, and the advantages they offer.

The Process of Centerless Grinding

The core principle of centerless grinding involves the use of a grinding wheel and a regulating wheel. The workpiece is placed between these two wheels, where the grinding wheel removes material from the surface of the workpiece while the regulating wheel controls its rotation and axial movement. This unique setup eliminates the need for centers or fixtures, enabling continuous production of components with minimal downtime.

Importance of Factories

Centerless cylindrical grinding machine factories are critical hubs of manufacturing that specialize in producing high-precision components. These factories are equipped with advanced grinding machines capable of handling a wide range of materials, including metals, plastics, and composites. The role of these factories extends beyond just grinding; they often incorporate quality control, research and development, and technical support, ensuring that products meet stringent industry standards.

Technological Advancements

Over the years, technological advancements have revolutionized centerless grinding. Modern machines incorporate CNC (Computer Numerical Control) technology, enabling higher precision and automation in the grinding process. This technology allows for complex shapes and tighter tolerances that were previously unattainable. Moreover, the integration of monitoring systems ensures that the grinding process remains consistent, reducing the likelihood of defects and improving overall output quality.

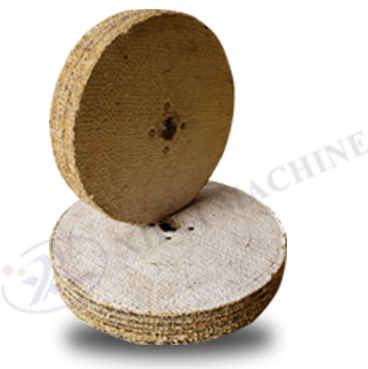

centerless cylindrical grinding machine factories

Advantages of Centerless Grinding

The benefits of centerless grinding are numerous. First and foremost, it offers high productivity – multiple parts can be ground simultaneously, significantly reducing cycle time. Secondly, because the process does not require clamping or set-up time, it leads to lower operational costs. Centerless grinding also provides superior surface finishes compared to other machining methods. The process is able to achieve finer tolerances, which is critical for components that require precise fitting and functionality.

Furthermore, centerless grinding is ideal for high-volume production runs. Factories can produce thousands of identical components consistently over time, which is particularly advantageous in industries where parts must be interchangeable.

Challenges and Solutions

Despite the advantages, centerless grinding machine factories face challenges, such as the need for skilled operators and the complexity of setup and maintenance of machinery. Ensuring that operators are adequately trained and adept at troubleshooting can mitigate these challenges. Additionally, regular maintenance of machinery is essential to maintain high levels of precision and efficiency.

Conclusion

Centerless cylindrical grinding machine factories play a pivotal role in the manufacturing landscape, facilitating the production of high-precision components essential for various industries. With ongoing technological advancements and a focus on quality and efficiency, these factories are poised to meet the growing demands of the market. As industries continue to evolve, the importance of centerless grinding in achieving operational excellence will undoubtedly increase, solidifying its place as an indispensable process in modern manufacturing.