CE Certification Tube Polishing Machine Enhancing Quality and Efficiency

In the modern manufacturing landscape, the aesthetic and functional quality of products is paramount, particularly in industries such as automotive, aerospace, and medical equipment. One essential piece of machinery that significantly contributes to achieving high-quality finishes is the tube polishing machine. Among these, models that comply with CE certification standards offer enhanced reliability, safety, and performance.

What is a Tube Polishing Machine?

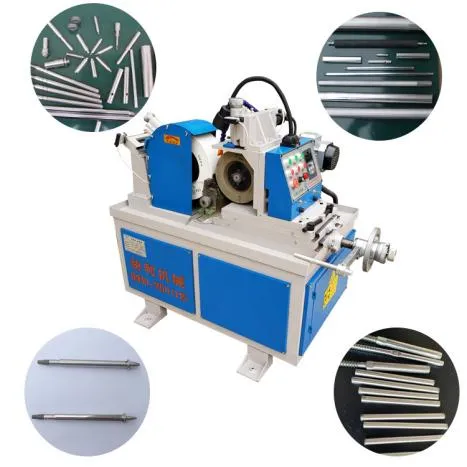

A tube polishing machine is designed to polish metal tubes and pipes, creating a smooth, shiny surface that not only enhances appearance but also improves resistance to corrosion. These machines are widely used to treat a variety of materials, including stainless steel, aluminum, and brass. Polishing processes typically involve the use of abrasive materials or chemical polishing agents, which remove surface imperfections, weld seams, and oxidation.

Importance of CE Certification

CE certification is a key indicator of whether a product meets European safety, health, and environmental protection standards. For industrial machinery, directly impacting worker safety, compliance with CE regulations is crucial. A CE-certified tube polishing machine ensures that manufacturers adhere to the necessary guidelines, providing peace of mind regarding operational safety and effectiveness.

1. Safety Features CE-certified machines are built with robust safety features designed to prevent accidents and injuries. This includes emergency stop buttons, protective guards, and safety interlocks. Such features are crucial in a factory setting where heavy machinery is used daily.

2. Quality Assurance Machines that meet CE standards undergo rigorous testing and quality assurance processes. This guarantees that they are not only effective in their polishing capabilities but also durable and reliable over time.

ce certification tube polishing machine

3. Operational Efficiency CE certification often means that the machine has been tested for energy efficiency and performance outputs. As manufacturers strive to reduce costs, investing in a CE-certified tube polishing machine can lead to lower operational expenses due to reduced energy consumption and waste.

Advantages of Using a CE Certified Tube Polishing Machine

- Improved Finish Quality CE-certified machines are engineered for precision, allowing for superior polishing results. This is particularly important for industries where aesthetics play a vital role in product appeal.

- Regulatory Compliance For companies operating in Europe or exporting to European markets, using CE-certified equipment is often a legal requirement. This certification facilitates smoother trade and reduces the risk of legal repercussions.

- Long-term Investment While CE-certified machines might involve a higher upfront investment, their durability and reliability often lead to lower maintenance costs and longer service lives, making them a wise investment in the long run.

Conclusion

The tube polishing machine is an essential tool in various manufacturing sectors, and selecting a CE-certified model elevates the advantages manifold. By ensuring compliance with rigorous safety and quality standards, manufacturers not only protect their workforce but also enhance their competitive edge in the market. With an eye towards sustainability and operational efficiency, investing in CE-certified equipment is a step towards future-ready manufacturing. In an era where quality and safety are paramount, the choice of machinery speaks volumes about a company’s commitment to excellence.