Understanding CE Certification for Surface Grinders and Centerless Grinding

In the modern manufacturing landscape, ensuring quality, safety, and compliance with regulatory standards is critical to the success of any organization. Among the various certifications that manufacturers can pursue, CE (Conformité Européenne) certification stands out, particularly for machinery like surface grinders and centerless grinding machines. This article delves into what CE certification entails, its importance for surface grinders and centerless grinding, and the benefits it provides to manufacturers and users alike.

What is CE Certification?

CE certification signifies that a product complies with the relevant European Union (EU) directives, ensuring that it meets essential standards regarding safety, health, and environmental protection. For machinery, this certification assures users that the equipment has been rigorously tested and meets EU safety requirements. The process of obtaining CE certification involves several steps, including risk assessment, implementation of safety measures, and obtaining relevant testing and approval from designated bodies.

The Importance of CE Certification in Grinding Machinery

Surface grinders and centerless grinding machines are critical in precision machining processes, used mainly in producing high-quality finishes and tight tolerances in various materials. Due to their intricate designs and the potential hazards associated with operating heavy machinery, obtaining CE certification is vital.

1. Safety Compliance CE certification requires manufacturers to adhere to rigorous safety standards. This is especially important for surface grinders and centerless grinding machines, which pose risks such as moving parts, sharp edges, and noise. A certified machine ensures reduced risks of accidents for operators.

2. Market Access In Europe, CE marking is mandatory for many types of machinery. Without this certification, manufacturers cannot legally sell their products in EU member states. Thus, achieving CE certification opens up significant market opportunities for manufacturers globally.

3. Consumer Trust Products with CE marking instill confidence in consumers and businesses. It indicates that the equipment has undergone thorough testing and is deemed safe for use. This consumer trust can enhance a manufacturer's reputation and lead to increased sales.

4. Regulatory Compliance CE certification helps manufacturers comply with relevant European directives and standards. This compliance is often required not just for legal reasons but also for obtaining necessary insurance coverage and meeting contractual obligations with clients.

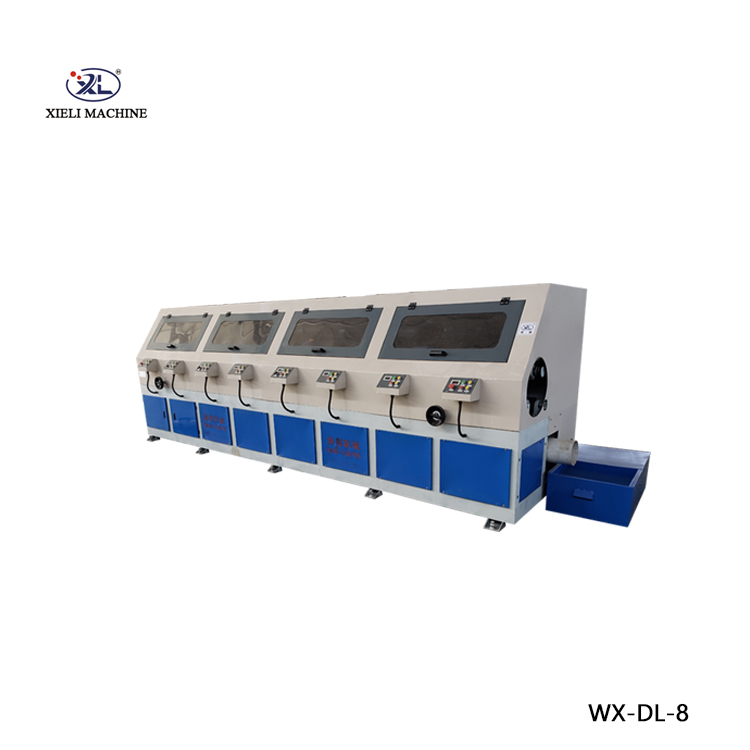

ce certification surface grinder centerless grinding

The Process of Obtaining CE Certification

Achieving CE certification for surface grinders and centerless grinding machines involves several essential steps

1. Determine the Applicable Directives Identify the EU directives that pertain to the specific type of machinery. For grinders, directives may include the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU).

2. Risk Assessment Conduct a comprehensive risk assessment to identify potential hazards associated with the machinery and determine how to mitigate these risks.

3. Implementing Safety Measures Design and implement necessary safety features and measures based on the risk assessment findings. This can include emergency stops, guards, and protective features.

4. Documentation and Testing Prepare technical documentation that demonstrates compliance with the directives, including design specifications, risk assessments, and test results from accredited laboratories.

5. Declaration of Conformity Upon completing all steps and ensuring compliance, prepare a Declaration of Conformity, stating that the machinery meets all applicable EU requirements.

6. Affix CE Marking Finally, affix the CE marking on the machines, allowing for legal sale within the EU.

Conclusion

CE certification plays a pivotal role in the manufacturing and use of surface grinders and centerless grinding machines. By ensuring adherence to safety, health, and environmental standards, this certification not only safeguards users but also enhances marketability and consumer trust. For manufacturers, investing time and resources in obtaining CE certification is not just a legal requirement but a strategic move towards long-term success in a competitive marketplace.