Understanding CE Certification for Surface Grinders and Centerless Grinders

In the realm of manufacturing and precision machining, surface grinders and centerless grinders play a crucial role in achieving the desired dimensions and finishes on various components. As these machines operate in environments that demand high safety and efficiency, the CE (Conformité Européenne) certification provides assurance regarding their compliance with European health, safety, and environmental protection standards.

What is CE Certification?

CE certification signifies that a product complies with the relevant EU directives and regulations. It is mandatory for products sold within the European Economic Area (EEA) and indicates that the equipment meets necessary safety requirements. For industrial machines, including surface and centerless grinders, obtaining CE certification involves rigorous testing and evaluation by designated authorities or notified bodies. This certification not only enhances product credibility but also broadens the market reach of manufacturers, facilitating access to European markets.

Importance of CE Certification for Surface Grinders

Surface grinders are essential tools in machining processes that require a high degree of flatness and surface finish. These machines utilize a rotating grinding wheel to remove material from a flat workpiece. Given their operational intricacies and the potential hazards associated with high-speed machinery, CE certification for surface grinders is vital for several reasons

1. Safety Assurance CE certification ensures that the machines adhere to essential safety standards, which minimize risks associated with operation, maintenance, and potential malfunctions. Equipment that lacks such certification may pose safety threats to operators and nearby personnel.

2. Performance and Efficiency Certified grinders are subjected to specific tests that measure their performance and efficiency levels. This ensures that the machines not only operate safely but also deliver optimal results, thus boosting productivity in manufacturing processes.

3. Market Access For manufacturers looking to introduce their products into the European market, CE certification is a gateway requirement. Non-compliance may lead to restrictions on sales and legal liabilities.

4. Consumer Confidence For end-users, purchasing a CE-certified machine provides peace of mind regarding safety and reliability. This trust can be crucial in competitive markets, where quality and standards significantly influence purchasing decisions.

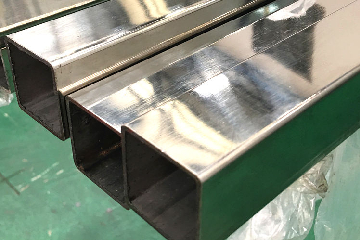

ce certification surface grinder centerless

CE Certification for Centerless Grinders

Centerless grinders, unlike conventional grinders, do not require a fixture to hold the workpiece. Instead, they use two wheels – a grinding wheel and a regulating wheel – to control the position and movement of the workpiece. Given their unique operational dynamics, the CE certification for centerless grinders similarly incorporates stringent evaluation criteria

1. Ergonomics and User Safety As with surface grinders, the focus on ergonomic design enhances user safety and comfort. Features such as adjustable controls and secure guards are evaluated to ensure the operator’s safety.

2. Environmental Compliance The CE certification process includes environmental considerations. Centerless grinders must minimize noise and vibration levels to comply with EU directives on environmental protection.

3. Technical Standards Compliance with specific harmonized standards is critical. These may include performance, stability, and user safety regulations, ensuring that the grinder is built to last and minimize operator fatigue.

The Certification Process

The process for obtaining CE certification typically begins with a comprehensive risk assessment conducted by the manufacturer. Based on the results, appropriate measures are implemented to mitigate identified risks. Once the machine is designed and manufactured in accordance with safety standards, it undergoes testing by a notified body. Successful evaluation leads to the issuance of a Declaration of Conformity, which affirms that the product complies with applicable EU directives.

Conclusion

CE certification for surface and centerless grinders is not merely a regulatory obligation; it represents a commitment to safety, quality, and environmental responsibility. For manufacturers and users alike, understanding and pursuing CE certification can lead to enhanced operational performance, increased marketability, and, most importantly, a safer working environment. Ultimately, the credibility of CE certification is indispensable in the competitive landscape of manufacturing, ensuring that both machines and operators can work in harmony to achieve excellence.