CE Certification for Precision Centerless Grinders Enhancing Safety and Efficiency in Manufacturing

In today’s fast-paced manufacturing landscape, maintaining a competitive edge often hinges on the ability to produce high-quality components efficiently and reliably. Centerless grinders have emerged as vital tools in this regard, streamlining processes by allowing for the continuous processing of materials without the need for manual loading and unloading. However, with the increasing complexity of regulatory compliance, obtaining CE certification for precision centerless grinders has become crucial. This certification not only underlines the quality and safety of the equipment but also assures manufacturers of compliance with European standards.

Understanding CE Certification

CE marking indicates that a product conforms with specific European Union (EU) directives relating to health, safety, and environmental protection. For manufacturers of precision centerless grinders, achieving CE certification involves a detailed process that assesses various aspects of the machine, including its design, construction, and safety features. Manufacturers must demonstrate that their grinders meet the essential requirements outlined in the relevant EU directives, which can include Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

Benefits of CE Certification

1. Market Access CE certification is a prerequisite for gaining access to the European market. Machines that do not carry the CE marking are not allowed to be sold or imported into EU countries, severely limiting market opportunities for non-compliant products.

2. Enhanced Safety CE certification ensures that the precision centerless grinders adhere to stringent safety standards. This minimizes the risk of accidents in the workplace, thereby protecting operators and reducing liability for manufacturers.

3. Quality Assurance The process of obtaining CE certification requires comprehensive testing and evaluation of the grinder’s performance, durability, and reliability. As a result, certified machines are often perceived as higher quality, leading to improved customer satisfaction and reduced operational costs due to fewer breakdowns.

4. Competitive Advantage In a market where competition is fierce, having CE certification can differentiate a manufacturer’s products. It signals to customers a commitment to quality and safety, fostering trust and potentially leading to increased sales.

5. Environmental Compliance Many of the EU directives incorporated into the CE certification process focus on minimizing environmental impact. By complying with these regulations, manufacturers contribute to sustainable practices in manufacturing and help reduce the overall environmental footprint.

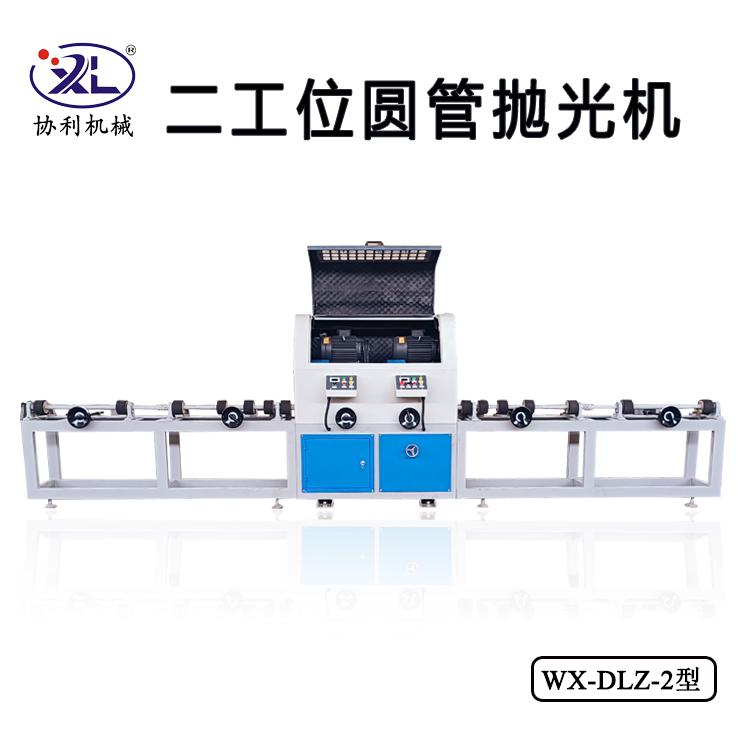

ce certification precision centerless grinder

The Certification Process

Achieving CE certification for precision centerless grinders typically involves several key steps

1. Self-Assessment Manufacturers must conduct a self-assessment of their machinery against the relevant EU directives. This includes evaluating all components, safety features, and operational protocols.

2. Documentation A comprehensive technical file must be prepared, detailing the design, construction, and operation of the machine, as well as the results from any tests and assessments conducted.

3. Testing Many manufacturers may need to engage third-party organizations to conduct tests to verify compliance with safety standards.

4. Declaration of Conformity Once compliance is confirmed, manufacturers must issue a Declaration of Conformity, stating that their machine meets all applicable EU directives.

5. Affixing the CE Mark After all requirements have been met, the CE marking can be affixed to the machine, indicating its compliance to prospective buyers.

Conclusion

As industries increasingly rely on precision centerless grinders to optimize manufacturing processes, CE certification plays a pivotal role in ensuring that these machines meet the necessary standards of safety and quality. By investing time and resources into obtaining CE certification, manufacturers not only protect their workers and operations but also enhance their reputation in a highly competitive market. Thus, CE certification for precision centerless grinders is not just a regulatory requirement; it’s an essential step towards fostering innovation, safety, and trust in the manufacturing sector.