Understanding CE Certification for Pipe Polishing Machine Manufacturers

In the manufacturing sector, especially for machinery like pipe polishing machines, adherence to international standards is crucial for ensuring product safety and marketability. One of the primary certifications that manufacturers must consider is the CE certification. This article delves into what CE certification means, its significance, and what pipe polishing machine manufacturers need to know to comply with these standards.

What is CE Certification?

CE marking, which stands for Conformité Européenne (French for European Conformity), is a certification mark that indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). The CE mark demonstrates that a product has met all applicable EU directives, allowing manufacturers to market their products in Europe and beyond.

Importance of CE Certification for Pipe Polishing Machines

For pipe polishing machine manufacturers, obtaining CE certification is essential for several reasons

1. Market Access CE certification is often mandatory for products sold in Europe. Without this certification, manufacturers may find themselves barred from entering the European market, limiting their business opportunities and potential revenue.

2. Consumer Confidence Products bearing the CE mark are perceived as safe and reliable. This certification can enhance brand reputation and consumer trust, providing an upper hand over competitors who may not have the certification.

3. Legal Compliance CE marking helps manufacturers comply with European laws surrounding machinery safety. The directives include Machinery Directive, Low Voltage Directive, and Electromagnetic Compatibility Directive, among others. Non-compliance can lead to legal consequences, including fines and product recalls.

4. Quality Assurance The process of obtaining CE certification involves thorough testing and quality control, ensuring that the machine operates safely and effectively. This can lead to improved product quality and fewer operational issues for end users.

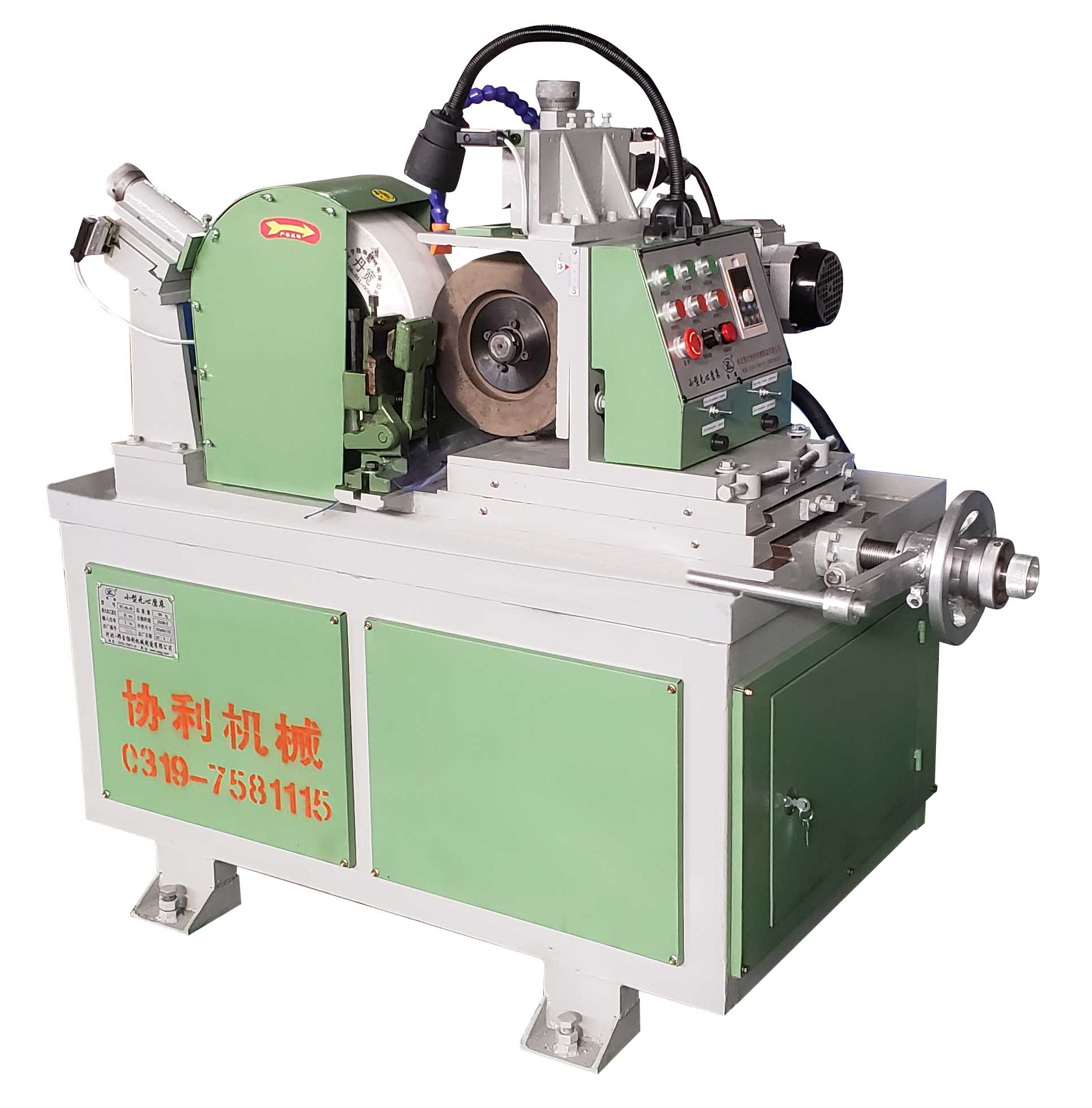

ce certification pipe polishing machine manufacturers

Steps for CE Certification for Pipe Polishing Machines

Manufacturers aspiring to obtain CE certification for their pipe polishing machines should follow these general steps

1. Identify Applicable Directives Determine which EU directives apply to your machine based on its design and function. Common directives for machinery include the Machinery Directive and the Low Voltage Directive.

2. Risk Assessment Conduct a risk assessment to identify potential hazards associated with the machine. This evaluation should guide the design process to mitigate risks effectively.

3. Technical Documentation Prepare the necessary technical documentation, which should include design specifications, risk assessments, test reports, and any other relevant information that demonstrates conformity to the applicable directives.

4. Testing Conduct necessary tests according to the outlined standards. This may involve both internal testing and third-party testing, depending on the risk level associated with the machine.

5. Declaration of Conformity Once all requirements have been met, manufacturers must draft a Declaration of Conformity, stating that the product complies with the relevant directives and standards.

6. Affixing the CE Mark Finally, after successful certification, the manufacturer can affix the CE marking on the machine, allowing for its distribution in the European market.

Conclusion

For pipe polishing machine manufacturers, CE certification is a crucial step towards ensuring product safety, legal compliance, and market access in Europe. By understanding the importance of the CE mark and meticulously following the certification process, manufacturers can enhance their credibility and significantly broaden their market reach. As the industry continues to evolve, staying informed about compliance requirements will be essential for sustained success in the global marketplace.