CE Certification of MLW100 Tube Polishing Machine Enhancing Quality and Safety

In the realm of industrial equipment, compliance with safety and quality standards is paramount. One such standard that ensures the safety and reliability of machinery is the CE certification. Among the various machines that benefit from this certification is the MLW100 tube polishing machine. This article delves into the importance of CE certification, the features of the MLW100, and how this machine enhances productivity and safety in tube polishing operations.

Understanding CE Certification

CE marking is a certification that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). In essence, it acts as a passport for products, ensuring consumers that they meet regulatory requirements. For manufacturers, attaining CE certification can open doors to international markets and build trust with customers.

The process of obtaining CE certification entails rigorous testing and evaluation of the machine against various EU directives. For machinery, these directives typically cover operational safety, electrical safety, and environmental impact. As such, machines that carry the CE mark are generally more reliable and safer to operate, fostering a better working environment.

Overview of the MLW100 Tube Polishing Machine

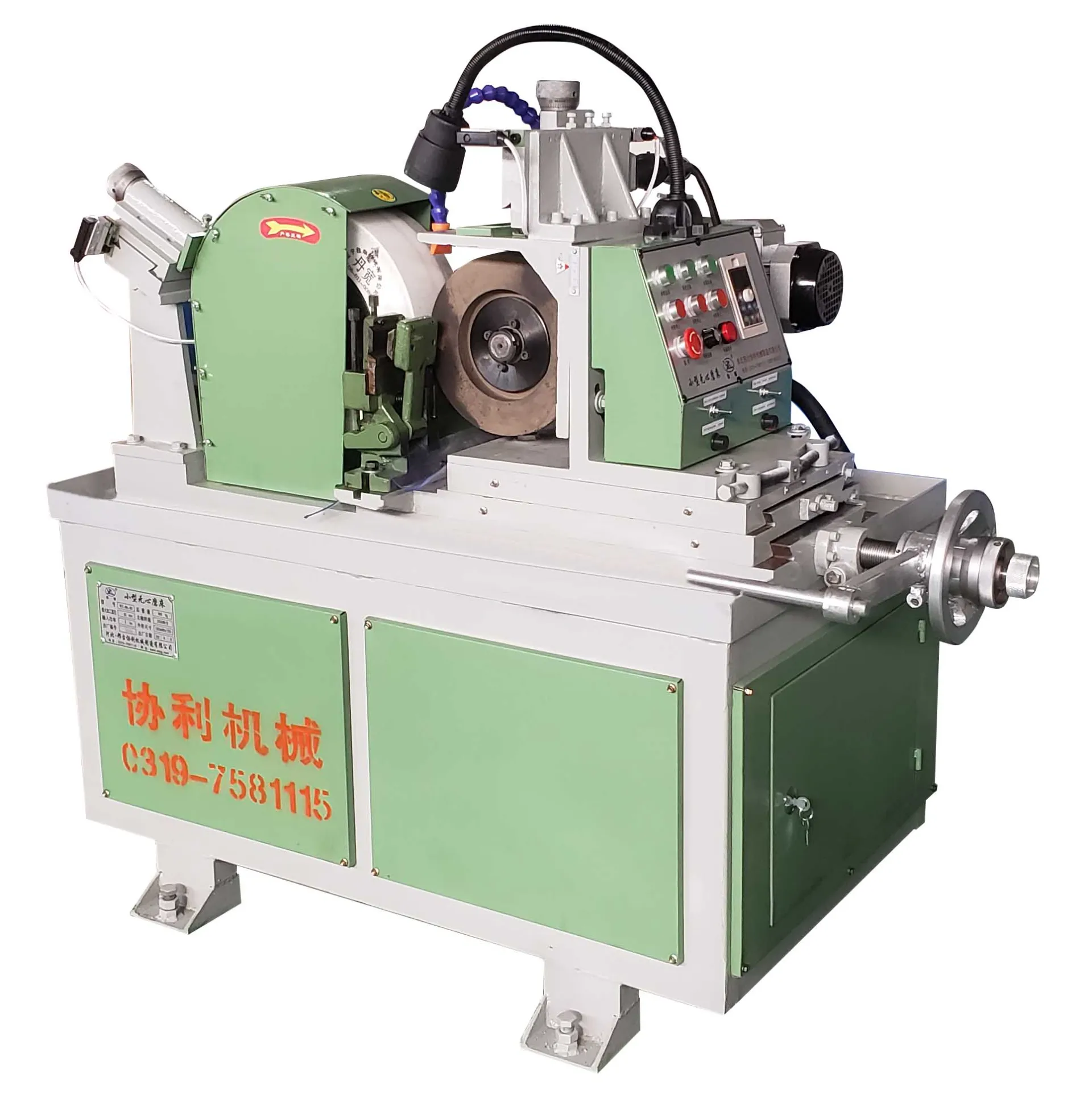

The MLW100 tube polishing machine is designed for polishing metal tubes with precision and efficiency. With advancements in technology, the MLW100 incorporates features that not only enhance its performance but also ensure compliance with CE standards. This machine is particularly suitable for various industries, including automotive, aerospace, and manufacturing, where polished metal surfaces are crucial for both aesthetics and functionality.

Key Features of the MLW100

1. Adaptive Polishing Technology The MLW100 uses advanced adaptive polishing technology that automatically adjusts the polishing process based on the tube's material and diameter. This feature ensures consistent quality and reduces the likelihood of damage to the tubes during the polishing process.

ce certification mlw100 tube polishing machine

2. User-Friendly Interface The machine features an intuitive control panel that allows operators to easily set parameters, monitor the process, and make adjustments on the fly. This user-friendly design minimizes the learning curve for new operators and enhances overall productivity.

3. High Throughput With its powerful motor and efficient design, the MLW100 can handle a high volume of tubes, making it suitable for both small-scale and large-scale operations. This capability is critical for manufacturers looking to meet demanding production schedules.

4. Safety Features Safety is a top priority for the MLW100. It includes emergency stop buttons, safety enclosures, and anti-vibration technology, all contributing to a safer working environment. Compliance with CE directives means that operators can work with peace of mind, knowing that the machine has undergone stringent safety evaluations.

5. Environmental Considerations The MLW100 is designed with eco-friendliness in mind. It is equipped with a dust collection system that minimizes airborne pollutants, and its energy-efficient motor reduces overall power consumption. Such features not only help businesses save on energy costs but also align with global sustainability goals.

The Impact of CE Certification on the MLW100

Achieving CE certification for the MLW100 tube polishing machine signifies its safety, reliability, and quality. For manufacturers, this certification provides a competitive edge in the market, as clients are increasingly prioritizing equipment that meets regulatory standards. Moreover, the CE mark instills confidence in potential buyers, ultimately leading to increased sales and customer satisfaction.

Furthermore, CE certification can facilitate smoother entry into international markets, where compliance with local regulations is often a barrier to trade. Manufacturers of the MLW100 can leverage this certification to expand their reach, catering to a global clientele and boosting their global footprint.

Conclusion

In conclusion, the MLW100 tube polishing machine, with its CE certification, exemplifies the intersection of quality, safety, and efficiency in industrial machinery. Its advanced features, coupled with a strong focus on operator safety and environmental responsibility, make it a valuable asset for industries reliant on tube polishing. As manufacturers and consumers alike prioritize compliance with safety standards, the MLW100 stands out as a benchmark for excellence in tube polishing technology. With continuous advancements in machinery, CE certification will remain a pillar in ensuring that the equipment used in our industries is safe, reliable, and efficient.