CE Certification for Internal Centerless Grinding Machines

In the realm of precision manufacturing, centerless grinding has emerged as a crucial process for producing components with tight tolerances and excellent surface finishes. Among the various types of grinding machines, internal centerless grinding machines play a significant role in machining components that require inner diameter (ID) processing. With the increasing global market demands and the necessity for compliance with safety and quality standards, CE certification has become an essential requirement for manufacturers of these machines.

CE marking, which stands for Conformité Européenne, indicates that a product has met the health, safety, and environmental protection standards set by the European Union (EU) legislation. For manufacturers of internal centerless grinding machines, obtaining CE certification is fundamental, as it demonstrates that their machines conform to EU safety requirements, facilitating easier access to the European market.

Importance of CE Certification

1. Market Access The primary advantage of acquiring CE certification is that it allows manufacturers to market their machines in the European Economic Area (EEA) freely. Without the CE mark, products cannot legally be sold within these markets, thereby limiting business opportunities.

2. Safety Assurance CE certification ensures that machines are designed and constructed to avoid any safety risks to operators and bystanders. For internal centerless grinding machines, which operate at high speeds and involve various mechanical components, safety measures are paramount. This includes features such as emergency stop functions, guards, and proper machine ergonomics.

3. Quality Compliance Beyond safety, CE certification helps ensure that the machines comply with certain quality benchmarks. This is vital in industries where precision is crucial, such as automotive, aerospace, and medical equipment manufacturing. By adhering to standardized processes and materials, CE-certified machines are more likely to deliver consistent performance and reliability.

4. Environmental Responsibility CE certification also addresses environmental impacts, which are increasingly under scrutiny worldwide. Manufacturers must demonstrate that their machines minimize waste and energy usage, comply with noise regulations, and handle manufacturing by-products responsibly. By working to achieve CE certification, companies can enhance their environmental profile, an essential factor in today’s market.

The Certification Process

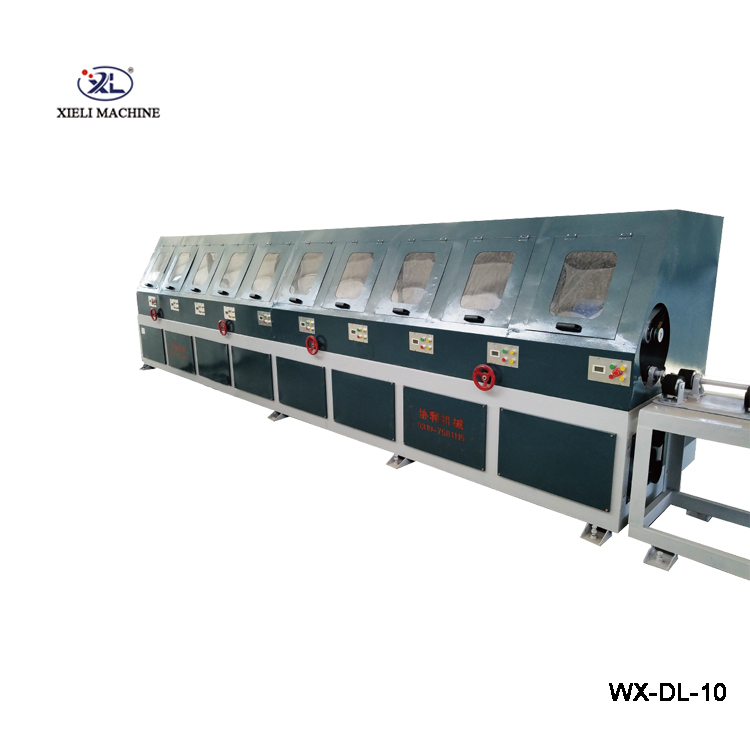

ce certification internal centerless grinding machine

The CE certification process involves several steps

1. Risk Assessment Manufacturers must perform a thorough risk assessment to identify potential hazards associated with the internal centerless grinding machine. This includes evaluating mechanical, electrical, and thermal dangers and considering the interactions between operators and the machine.

2. Compliance with Standards The next step is ensuring that the machine meets relevant European standards, such as EN 60204 for electrical equipment and EN 847-1 for woodworking machines, depending on the application. These standards dictate various requirements about design, manufacturing practices, and equipment safety.

3. Technical Documentation Manufacturers must compile a comprehensive technical file, including design documents, risk assessments, test results, and operating manuals. This documentation is crucial for proving compliance during inspections or audits.

4. Conformity Assessment In many cases, an external notified body, a third-party organization designated by an EU member state, will need to evaluate the machinery. They assess the technical documentation and may perform tests to ensure compliance with the necessary standards.

5. Issuance of Declaration of Conformity Once compliance is verified, the manufacturer issues a Declaration of Conformity (DoC), a legal document stating that the machine meets all applicable directive requirements.

6. Affixing the CE Mark Finally, upon successful completion of the above steps, the manufacturer can affix the CE mark to the machine, signaling compliance to EU regulations.

Conclusion

Obtaining CE certification for internal centerless grinding machines is a multifaceted process that not only enhances marketability in Europe but also prioritizes safety, quality, and environmental responsibility. As manufacturers navigate the complexities of certification, they must remain committed to continuous improvement and compliance, ultimately leading to greater trust among consumers and the successful integration into the global marketplace. In a competitive manufacturing landscape, CE certification is not just a regulatory requirement; it's an investment in quality and safety that pays dividends in market access and customer satisfaction.