CE Certification for Fives Centerless Grinders Ensuring Quality and Safety in Precision Manufacturing

In the realm of precision manufacturing, centerless grinding plays a crucial role in achieving high levels of accuracy and efficiency. Fives, a prominent player in the machine tool industry, offers advanced centerless grinding machines that cater to various industrial applications. One of the key aspects of Fives' commitment to quality and safety is obtaining CE certification for its centerless grinders. This article will delve into what CE certification entails, its significance in the manufacturing process, and how it relates specifically to Fives centerless grinders.

Understanding CE Certification

CE marking is a conformity assessment that indicates a product's compliance with European health, safety, and environmental protection standards. It is mandatory for many products sold within the European Economic Area (EEA). Products bearing the CE mark signify that they meet the essential requirements outlined in relevant European directives and regulations.

For manufacturers like Fives, obtaining CE certification is a testament to their commitment to producing safe and reliable machinery. This process involves rigorous testing and certification by notified bodies, which evaluate the design, performance, and safety features of the equipment. The emphasis is on ensuring that the machinery is not only efficient but also poses no risk to operators or the environment.

Importance of CE Certification in Centerless Grinding

1. Safety Assurance Centerless grinders can pose various risks if not properly designed and manufactured. CE certification ensures that Fives centerless grinders adhere to strict safety standards, minimizing the risk of accidents in the workplace. Features such as emergency stops, protective covers, and automatic shut-off mechanisms are essential components that help maintain a safe working environment.

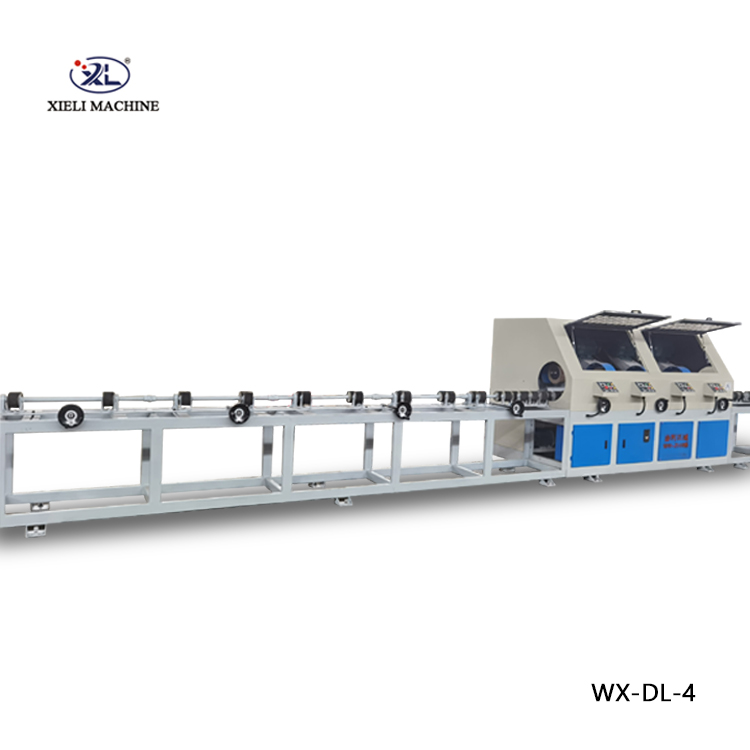

ce certification fives centerless grinder

2. Quality Control CE certification involves thorough inspections and tests that evaluate the performance and durability of the machinery. By adhering to these standards, Fives establishes a reputation for high-quality products that can stand the test of time. This level of scrutiny ensures that customers receive reliable equipment that meets their operational needs.

3. Market Access For manufacturers looking to expand their reach in the global market, CE certification is often a prerequisite. In many cases, European businesses will not engage with suppliers whose products lack proper certification. By ensuring that their centerless grinders are CE certified, Fives enhances its competitiveness in the international market, opening doors to collaboration with companies that prioritize safety and quality.

4. Customer Confidence CE certification instills confidence in customers. When businesses invest in high-end machinery, they want assurance that they are making a sound investment. With Fives centerless grinders carrying the CE mark, customers can trust that they are acquiring equipment that has undergone comprehensive evaluation and meets stringent quality standards.

5. Environmental Responsibility CE certification not only focuses on safety but also addresses environmental concerns. Fives is committed to sustainable manufacturing practices, and by obtaining CE certification, it demonstrates adherence to regulations that limit environmental impact. This includes aspects such as energy efficiency and the use of materials that do not harm the environment.

Conclusion

CE certification is a vital aspect of Fives centerless grinders, elevating the standards of safety, quality, and reliability in the machine tool industry. As manufacturing processes continue to advance, compliance with established norms ensures that equipment meets the demands of modern production while safeguarding operators and the environment. By investing in CE certification, Fives not only meets legal requirements but also reinforces its position as a leader in precision grinding technology.

As industries evolve and the demand for precision machining grows, the role of certified equipment will become increasingly paramount. Companies looking to maximize their operational efficiency and ensure worker safety will find Fives centerless grinders an indispensable asset, supported by the assurance of CE certification. As a result, Fives stands ready to meet the challenges of the future, delivering machinery that embodies quality and safety at every turn.