CE Certification for Centerless Grinders with Surface Grinder Integration

In today's manufacturing landscape, precision and efficiency are paramount. Centerless grinders have emerged as pivotal machines in the realm of metalworking, particularly due to their ability to produce high volumes of parts with tight tolerances. When combined with surface grinders, these machines offer enhanced capabilities that can significantly boost productivity. However, to ensure the safety and reliability of these sophisticated machines, CE certification has become a critical requirement in the European market.

Understanding Centerless Grinding

Centerless grinding is a process that allows the machining of cylindrical parts without the need for holding them between centers. In this method, the workpiece is placed between a grinding wheel and a regulating wheel, which facilitates the grinding process while ensuring that the part does not become misaligned. This technique is particularly effective for producing components with a consistent diameter over long lengths—making it invaluable in industries ranging from automotive to aerospace.

The Role of Surface Grinding

Surface grinding, on the other hand, focuses on creating a flat surface on a workpiece. This process utilizes a rotary wheel covered in a finer abrasive to remove material, resulting in a smooth, flat finish. When integrated with a centerless grinder, surface grinding capabilities can enhance the overall precision of components, allowing for both cylindrical and flat surfaces to be finished in a single setup.

Importance of CE Certification

CE certification is a mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). For manufacturers of centerless grinders that also incorporate surface grinding capabilities, obtaining CE certification is not merely a regulatory hurdle—it is a testament to the machine's safety and quality.

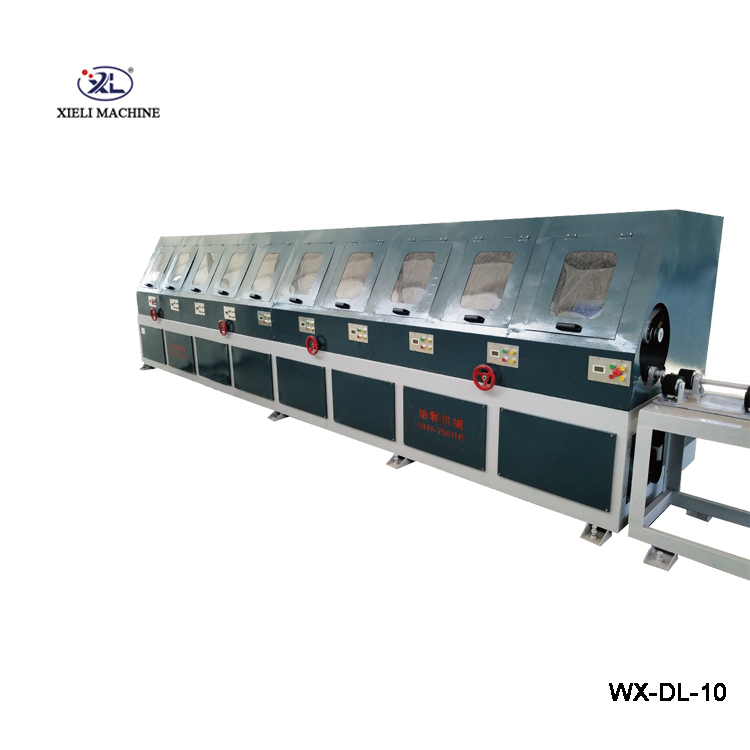

ce certification centerless grinder with a surface grinder

The process of acquiring CE certification involves rigorous testing and evaluation of the machinery to ensure compliance with relevant directives, such as the Machinery Directive (2006/42/EC). This ensures that the equipment meets high safety standards, minimizing the risks associated with operator injuries and machinery failures. The certification process requires an assessment of design, manufacturing quality, and operational safety, thereby providing end-users with confidence in the machinery they are using.

Benefits of CE-Certified Machines

1. Safety Assurance CE certification provides an assurance that the machine adheres to European safety standards. This significantly reduces the risk of accidents and enhances the safety of operators, making workplaces more secure.

2. Market Access For manufacturers, CE certification is essential for access to the European market. Without it, machines cannot be legally sold or operated within the EEA, limiting potential customers and sales opportunities.

3. Quality and Reliability CE certification is often perceived as a symbol of quality. Machines that have undergone the certification process are generally more reliable, translating to reduced downtime and maintenance costs for users.

4. Environmental Compliance The certification process also evaluates the environmental impact of the machinery, ensuring that the operations are sustainable and compliant with ecological regulations. This is increasingly important in today's environmentally conscious marketplace.

Conclusion

Incorporating both centerless and surface grinding functionalities into manufacturing processes necessitates the highest standards of quality and safety. CE certification plays a crucial role in ensuring that these machines meet the stringent regulations of the European market. As manufacturers strive for innovation and efficiency, investing in CE-certified centerless grinders with integrated surface grinding capabilities can lead to enhanced productivity, improved safety standards, and greater market competitiveness. This synergy of technology and compliance not only benefits manufacturers but also contributes positively to the global movement towards safer and more sustainable industrial practices.