Ensuring Safety in Centerless Grinding A Focus on CE Certification

Centerless grinding has become an essential part of various manufacturing processes across industries, thanks to its efficiency and ability to produce high-precision components. However, with the advantages of this grinding method come inherent risks. Therefore, ensuring safety in centerless grinding operations is of utmost importance. One crucial aspect of safety in this context is obtaining CE certification for centerless grinders.

Understanding Centerless Grinding

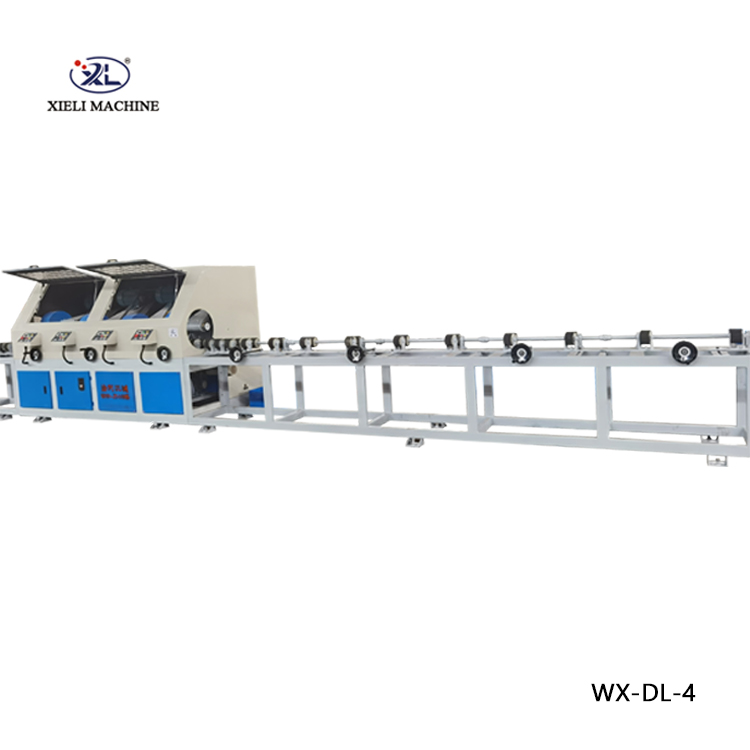

Centerless grinding is a machining process used to finish workpieces that are held in place by a grinding wheel, a regulating wheel, and a work support blade. Unlike traditional grinding methods where the workpiece is mounted between centers, centerless grinding allows for continuous processing, eliminating the need for time-consuming adjustments. This method is widely used for producing cylindrical parts, such as shafts, pins, and bearings, with tight tolerances and excellent surface finishes.

The Importance of Safety in Centerless Grinding

Despite its advantages, centerless grinding poses several hazards, including exposure to high-speed machinery, flying debris, and the risk of operator injury. These risks necessitate strict adherence to safety protocols to prevent accidents that can result in serious injuries or even fatalities. Thus, a robust safety framework is crucial, and obtaining CE certification serves as a significant step towards achieving that goal.

What is CE Certification?

CE certification is a mark indicating that a product complies with European safety, health, and environmental protection standards. For machinery, including centerless grinders, this certification is required for free movement within the European marketplace. By achieving CE certification, manufacturers demonstrate that their equipment meets the essential safety requirements, ensuring minimal risk during operation.

Key Aspects of CE Certification for Centerless Grinders

1. Risk Assessment The first step in obtaining CE certification for centerless grinders involves a thorough risk assessment. Manufacturers must evaluate potential hazards associated with their machinery and implement measures to mitigate these risks. This may include the installation of safety guards, emergency stop buttons, and appropriate signage.

ce certification centerless grinder safety

2. Compliance with Standards Centerless grinders must comply with several relevant European directives, including the Machinery Directive and the Low Voltage Directive. Adherence to standards such as EN 60204 (Safety of Machinery – Electrical Equipment) and EN ISO 12100 (Safety of Machinery – General Principles for Design) is essential for achieving certification.

3. Testing and Documentation Manufacturers must conduct rigorous testing to verify that their centerless grinders operate safely under various conditions. This testing must be documented meticulously as evidence of compliance with safety standards. Proper documentation helps in the certification process and serves as a reference for future audits.

4. Maintenance and Training CE certification is not merely a one-time task; it also involves ongoing maintenance of safety protocols and regular training of operators. Ensuring that operators are well-versed in the safe operation of centerless grinders is critical. Regular training sessions should cover safe practices, understanding of safety features, and emergency response protocols.

Benefits of CE Certification in Centerless Grinding Operations

Obtaining CE certification brings numerous benefits beyond compliance

- Enhanced Safety CE certification ensures that safety features are incorporated into the design and operation of centerless grinders, significantly reducing the likelihood of accidents.

- Market Access In Europe, CE marking is mandatory for most machinery. Certification opens doors to the European market, allowing manufacturers to compete effectively.

- Customer Confidence CE certification serves as a testament to a manufacturer's commitment to quality and safety, enhancing customer trust in their products.

Conclusion

In conclusion, safety in centerless grinding is paramount, and obtaining CE certification is a critical component of ensuring that safety standards are met. By focusing on risk assessment, compliance with regulations, thorough testing, and operator training, manufacturers can create a safer work environment while also achieving the competitive edge necessary to thrive in the global marketplace. The roadmap to a safer centerless grinding operation is clear, and adherence to CE certification is a vital part of that journey.