CE Certification for Centerless Belt Grinders Ensuring Safety and Compliance

In today’s fast-paced industrial environment, the necessity for efficient manufacturing processes is ever-increasing. Among the wide array of machinery available, centerless belt grinders stand out as a vital tool for precision grinding and shaping of materials, particularly in the metalworking industry. However, safety and compliance with regulations are paramount. This is where CE certification plays a crucial role.

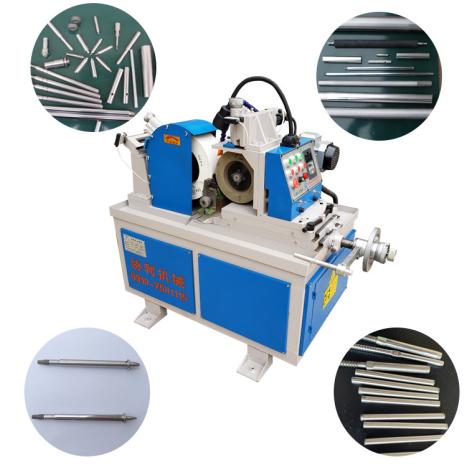

Understanding Centerless Belt Grinders

Centerless belt grinders are specialized machines designed to grind workpieces without needing to center them. This unique design allows for continuous operation and increased productivity, as multiple parts can be processed simultaneously. They are widely used in various applications, including automotive parts production, manufacturing of tools, and other precision engineering tasks. The versatility and efficiency of centerless belt grinders make them indispensable in achieving high-quality finishes on various materials.

The Importance of CE Certification

CE certification stands for “Conformité Européenne,” which translates to “European Conformity.” It signifies that a product complies with health, safety, and environmental protection standards required by the European Union (EU). For manufacturers and suppliers, obtaining CE certification for centerless belt grinders is not just a legal requirement; it is also a mark of quality assurance that can build trust with customers and enhance marketability.

1. Safety Assurance Centerless belt grinders can pose various risks if not designed or operated correctly. These include mechanical hazards, electrical risks, and potential exposure to noise and vibrations. CE certification ensures that the machinery meets stringent safety standards, reducing the chance of accidents and injuries in the workplace.

2. Market Access In order to sell products within the European market, manufacturers must ensure their equipment is CE certified. This requirement means that businesses without CE certification may face barriers in entering or expanding within European markets, limiting their growth potential.

3. Quality Control The process of obtaining CE certification involves comprehensive testing and assessment of the equipment. This not only ensures compliance with regulatory standards but also encourages manufacturers to adopt higher quality manufacturing practices.

ce certification centerless belt grinder

4. Continuous Improvement The CE certification process often necessitates the implementation of rigorous quality management systems, promoting better operational practices that contribute to the continual improvement of product quality and safety.

The CE Marking Process

Achieving CE certification for centerless belt grinders involves several key steps

1. Product Assessment Manufacturers must first conduct a thorough risk assessment of their machines to identify potential hazards. This step lays the groundwork for the compliance process.

2. Testing and Documentation The next step involves extensive testing of the grinder to ensure it meets the required EU standards. This includes not only mechanical testing but also evaluations for electrical safety and environmental impact. Comprehensive documentation is crucial as it serves as proof of compliance.

3. Certification by Notified Bodies Depending on the complexity and risk associated with the equipment, manufacturers may need to involve a notified body—an organization accredited by the government to evaluate and certify products. This step is particularly important for higher-risk machinery.

4. Marking and Declaration of Conformity After successfully passing assessment procedures, manufacturers affix the CE mark to their products and issue a Declaration of Conformity, which states that the equipment meets all relevant EU directives.

Conclusion

CE certification for centerless belt grinders is not merely a regulatory hurdle but a valuable asset for manufacturers aiming to ensure the safety, reliability, and quality of their machines. By adhering to these standards, businesses can enhance their reputation, meet customer expectations, and remain competitive in the global market. As industries continue to evolve, the emphasis on compliance and safety will only grow, making CE certification a cornerstone of responsible manufacturing practices in the world of industrial machinery.