Centerless Bar Grinding Machines Ensuring CE Certification for Quality and Safety

In the world of manufacturing, precision is paramount. This is particularly true in industries where metalworking is prevalent. One of the machines that play a crucial role in achieving high precision in metal fabrication is the centerless bar grinding machine. With the increasing importance of safety and quality, CE certification has become a significant factor for manufacturers when selecting equipment. This article explores the importance of centerless bar grinding machines and the implications of CE certification.

Understanding Centerless Bar Grinding Machines

Centerless bar grinding machines are designed to grind cylindrical workpieces without the need for any additional workholding devices. This unique method utilizes two wheels the grinding wheel and the regulating wheel. The workpiece is fed between these two wheels, allowing for continuous grinding along its length. This type of grinding is highly efficient and is widely used in the production of precision-ground bars, rods, and tubes.

The advantages of centerless grinding include reduced cycle times, increased productivity, and enhanced consistency in dimensional accuracy. These machines are indispensable in sectors such as automotive, aerospace, and manufacturing, where parts must meet stringent specifications.

The Importance of CE Certification

CE certification is a mark of quality and safety that indicates compliance with European health, safety, and environmental protection standards. For centerless bar grinding machines, obtaining CE certification is not just a regulatory requirement; it also serves as a guarantee to manufacturers and users that the equipment meets high standards.

1. Safety Assurance One of the primary reasons for obtaining CE certification is to ensure that the machinery is safe to operate. Centerless grinding machines often operate at high speeds and can pose risks to operators if not designed with safety features such as emergency stops, guards, and proper shielding. CE certification requires that the machine undergoes rigorous testing to ensure compliance with safety standards.

2. Quality Performance CE certification also reflects the quality of the machine's performance. Manufactured components that are ground using certified machines are more likely to meet required tolerances and specifications. This is vital in industries where the integrity of parts can impact overall performance and safety.

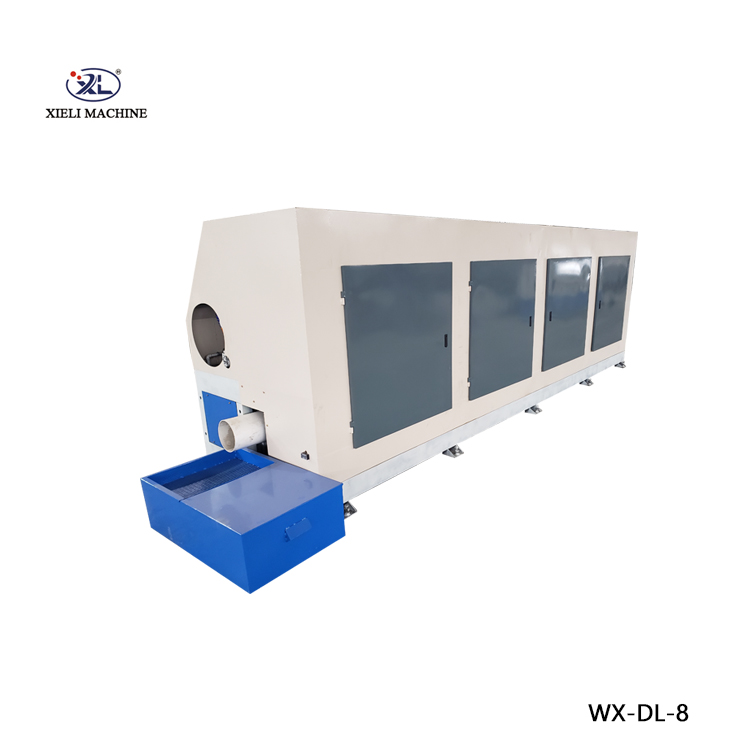

ce certification centerless bar grinding machine

3. Market Access For manufacturers looking to export their products to the European market, CE certification is a prerequisite. It opens up opportunities and expands market reach, allowing manufacturers to compete on a global scale.

Choosing a CE Certified Centerless Bar Grinding Machine

When selecting a centerless bar grinding machine, several factors should be considered

- Manufacturer Reputation Always choose equipment from manufacturers with a strong reputation for quality and safety. Research their compliance with CE standards and any other relevant certifications.

- Technical Specifications Ensure that the machine meets the specific requirements of your production process. Consider factors such as size, power, and precision capabilities.

- Support and Maintenance A reliable after-sales support system is essential. Machines may require periodic maintenance, and having access to spare parts and technical support can prevent downtime.

- User Training Ensure that operators are properly trained to use the machine safely and efficiently. Understanding the operational features and safety protocols is crucial in minimizing risks.

Conclusion

The role of centerless bar grinding machines in modern manufacturing cannot be overstated. With the emphasis on safety and superior quality, obtaining CE certification is essential for both manufacturers and users. As industries continue to evolve, investing in CE-certified equipment will undoubtedly lead to improved efficiency, product quality, and operational safety. In a competitive market, compliance with these standards may well be the difference between success and failure. Selecting the right machine not only enhances productivity but also supports sustainable practices tailored to today’s manufacturing challenges.