CE Certification for Bend Tube Polishing Machines

In today's competitive manufacturing landscape, the importance of compliance with quality and safety standards cannot be overstated. Among the essential certifications, the CE (Conformité Européenne) marking holds significant value, especially for machinery used in the processing industry. The bend tube polishing machine, a crucial tool in metal fabrication, has gained prominence, and ensuring it meets CE certification is vital for manufacturers targeting markets in the European Union.

What is a Bend Tube Polishing Machine?

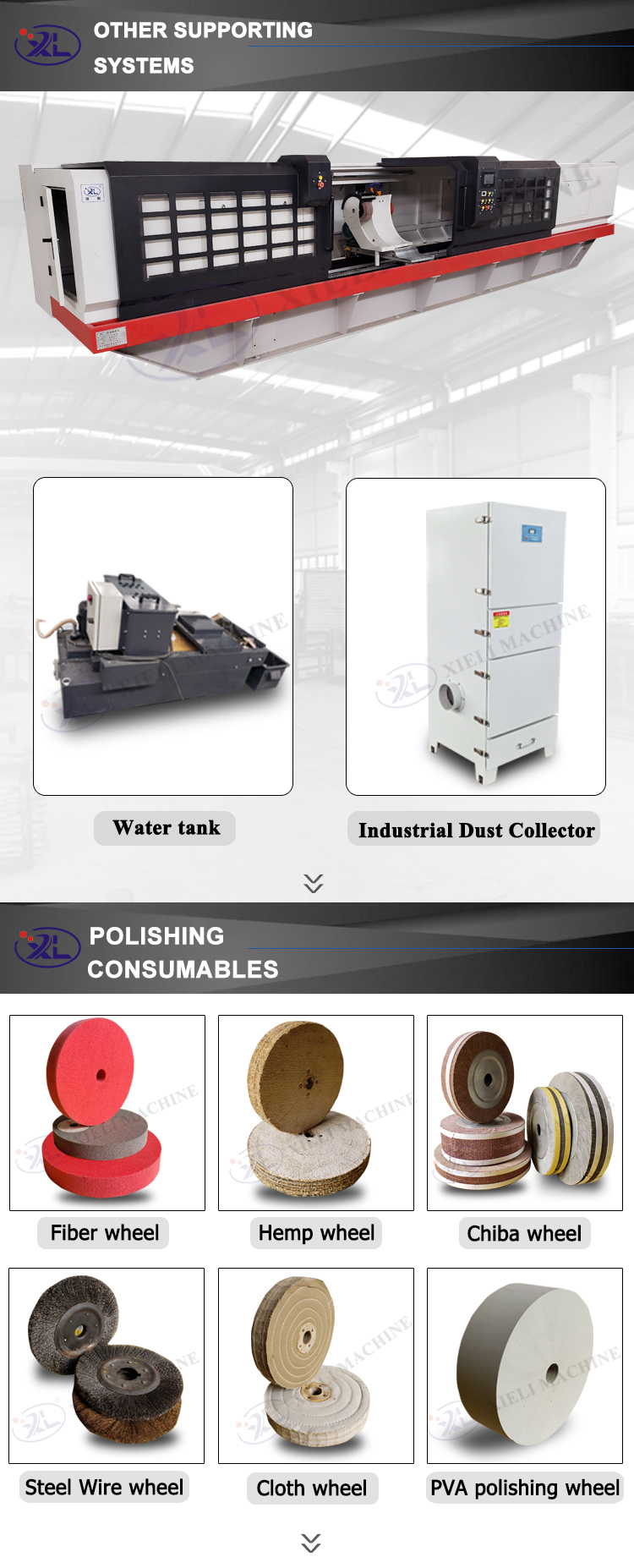

A bend tube polishing machine is specifically designed for polishing bent tubes made of various materials, including stainless steel and aluminum. This equipment enhances the aesthetic and functional qualities of tubes, making them suitable for applications in industries such as automotive, aerospace, and furniture. The machine typically utilizes abrasive belts or discs to achieve a smooth and polished finish, ensuring the components meet specific quality requirements.

Importance of CE Certification

CE certification indicates that a product complies with European health, safety, and environmental protection standards. For manufacturers of bend tube polishing machines, obtaining this certification is critical, as it assures customers of the product's quality and safety. Here are several key benefits

1. Market Access The CE marking is mandatory for many products sold in the European market. Without this certification, manufacturers may face prohibitions on sales, limiting their market potential.

ce certification bend tube polishing machine

2. Consumer Confidence CE certification enhances the credibility of a product. Customers are more likely to trust machines that have met rigorous safety and quality standards.

3. Legal Compliance Ensuring compliance with EU directives protects manufacturers from potential legal issues and penalties that can arise from selling non-compliant machinery.

4. Competitive Edge In a crowded market, having CE certification can differentiate a manufacturer from competitors who may not prioritize compliance, thereby attracting more customers.

The Certification Process

To achieve CE certification for a bend tube polishing machine, manufacturers must undergo a systematic process. This includes risk assessment, adherence to relevant directives (such as the Machinery Directive or Low Voltage Directive), and thorough testing to verify compliance. Documentation demonstrating conformity must also be prepared and maintained.

In summary, CE certification is crucial for bend tube polishing machine manufacturers who wish to compete effectively in the global market. By adhering to these stringent standards, they not only enhance their product's marketability but also contribute to a safer and more reliable industrial environment. Embracing these practices is not just a regulatory requirement; it is a commitment to excellence in manufacturing.