CE Certification and the 24x24 Centerless Grinder Ensuring Precision and Safety in Manufacturing

In the landscape of modern manufacturing, precision is paramount. Among the myriad of machines that contribute to this goal, the centerless grinder stands out, particularly the 24x24 model, which has gained prominence for its efficiency and versatility. As industries strive to adhere to global standards, CE certification for such equipment has become a focal point, ensuring that these machines not only perform optimally but also do so safely.

Understanding Centerless Grinding

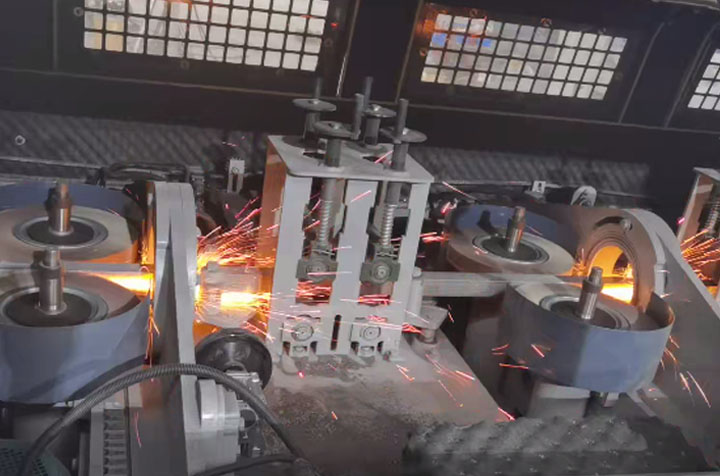

Centerless grinding is a machining process that differs significantly from traditional grinding methods. In a centerless grinder, the workpiece is not held in place by the means of a spindle; instead, it is supported by a grinding wheel and a regulating wheel, which allows for continuous feeding of materials. The 24x24 centerless grinder can accommodate larger workpieces, making it ideal for industries such as automotive and aerospace, where precise and consistent sizing is crucial.

The primary appeal of the centerless grinder lies in its ability to process parts rapidly and with high repeatability. These machines can grind various shapes and materials, offering flexibility to manufacturers who require precision components without the time loss associated with setup changes.

The Importance of CE Certification

The CE mark, short for Conformité Européenne (French for European Conformity), signifies that a product meets the safety, health, and environmental protection standards for products sold within the European Economic Area (EEA). For machinery like the 24x24 centerless grinder, obtaining CE certification is a multi-step process, which includes rigorous testing and evaluation to ensure compliance with several European directives, notably the Machinery Directive.

The significance of CE certification for the 24x24 centerless grinder can be summarized in a few key points

ce certification 24x24 centerless grinder

1. Safety Assurance CE certification demonstrates that the machine adheres to essential safety standards, protecting operators from potential hazards. This includes features such as emergency stop mechanisms, adequate guarding against moving parts, and other safety protocols.

2. Market Accessibility For manufacturers looking to export their products, CE certification is often compulsory. It allows for easier entry into European markets, which have stringent requirements for industrial machinery. Non-compliance can lead to legal ramifications, including fines or prohibitions on product sales.

3. Quality and Reliability By adhering to CE standards, manufacturers indicate that their machine not only meets safety regulations but is also built with a focus on quality and reliability. This builds trust with customers, who can be assured of the machine's operational integrity.

4. Sustainability Considerations CE certification often takes into account the environmental impact of machinery. Manufacturers are increasingly prioritizing energy-efficient designs and practices, aligning with the global push for sustainability. The 24x24 centerless grinder can be designed to minimize waste and energy consumption, adding to its appeal in environmentally-conscious industries.

The Future of Centerless Grinding

As technology advances, so too does the evolution of machining processes. The 24x24 centerless grinder is poised to integrate technologies such as automation and IoT sensors, enhancing precision and efficiency. With CE certification ensuring that safety and quality remain uncompromised, manufacturers can confidently invest in these machines, knowing they are equipped to meet the demands of modern production environments.

In conclusion, the 24x24 centerless grinder represents a critical element in the toolkit of modern manufacturing, combining precision with safety through CE certification. As industries continue to innovate, the importance of certified machinery will only grow, reinforcing the need for commitment to both quality and compliance in the pursuit of operational excellence.