The Importance of Buying Square Tube Polishing Machines

In the world of metalworking and manufacturing, the finish of a product can be just as important as its structural integrity. For companies that produce square tubes, investing in high-quality polishing machines is vital. A square tube polishing machine is designed to smooth out the surface of square tubes, removing imperfections, and providing a polished finish that enhances both aesthetic appeal and corrosion resistance.

Understanding the Benefits

Buying a square tube polishing machine offers several advantages that can significantly impact your production process. First and foremost, these machines improve the quality of the finished product. A polished surface not only looks better but also contributes to the overall durability of the metal. This is particularly important in industries where square tubes are used in visible applications or exposed to harsh environments, such as automotive, construction, and artistic metalwork.

Moreover, a square tube polishing machine can streamline the manufacturing process. Manual polishing can be labor-intensive and time-consuming, often leading to inconsistencies in quality. Automated polishing equipment allows for uniform results, reducing labor costs and saving time. This efficiency means companies can increase their output without sacrificing quality, ultimately boosting profitability.

Choosing the Right Machine

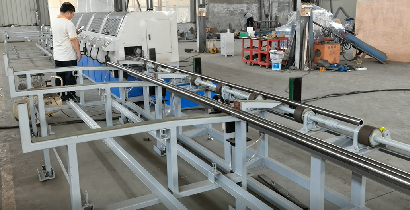

buy square tube polishing machine

When considering the purchase of a square tube polishing machine, it is essential to evaluate the specific needs of your business. Factors such as tube size, material type, and desired finish should all influence your decision. Machines vary in capability, so understanding your requirements will help ensure you select a model that meets your production goals.

Additionally, consider the features of the machine. Look for options that allow for variable speed settings, as this provides versatility for different polishing tasks. Some machines also come equipped with advanced technology that enables them to detect surface defects, ensuring that only high-quality tubes go to the next stage of production. Investing in such technology can enhance quality control and reduce waste.

Maintenance and Support

It’s also crucial to think about the long-term maintenance and support that comes with purchasing a polishing machine. Opt for suppliers that offer comprehensive warranties and after-sales support. Routine maintenance is essential for keeping machines in optimal condition, and having a reliable supplier can make all the difference in ensuring your operations run smoothly.

Conclusion

In summary, investing in a square tube polishing machine can elevate your manufacturing capabilities. The benefits of improved quality, increased efficiency, and long-term cost savings are significant. By carefully assessing your needs and choosing the right machine, you can enhance your production line and deliver superior products to your customers. As the demand for polished square tubes continues to grow, now is the perfect time to make this strategic investment in your business.