The Rise of Pipe Polishing Machines Understanding Prices and Benefits

In the seamless world of manufacturing and fabrication, pipe polishing machines have gained significant traction. As industries evolve, the demand for polished pipes has become a staple across many sectors, particularly in construction, automotive, and aerospace industries. This article explores the factors influencing the prices of pipe polishing machines and the benefits of incorporating them into production lines.

What is a Pipe Polishing Machine?

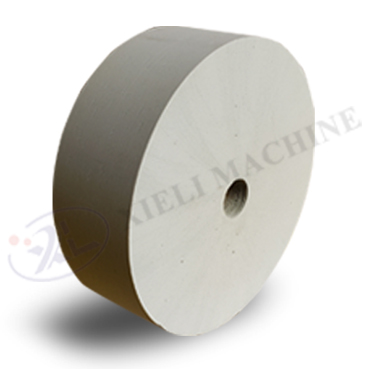

A pipe polishing machine is specialized equipment designed to enhance the surface finish of pipes made from various materials such as stainless steel, aluminum, and copper. These machines use different polishing methods—mechanical, chemical, or electrochemical—to achieve a smooth, shiny surface. The primary purpose of these machines is to remove imperfections, improve aesthetics, and enhance resistance to corrosion, ultimately extending the lifespan of the product.

Factors Influencing Prices

1. Type of Machine The first aspect influencing the price is the type of pipe polishing machine. There are several options available, including manual, semi-automatic, and fully automatic machines. Manual machines tend to be less expensive but require more labor, while automatic models save time and labor costs but come at a higher price point.

2. Material and Build Quality The materials used in constructing the machine significantly affect its price. Machines made from high-grade stainless steel or heavy-duty materials are typically more durable and reliable. Investing in quality materials often results in higher upfront costs but can lead to savings in maintenance and replacements.

3. Brand and Manufacturer Just like any other machinery, the brand and manufacturer of pipe polishing machines play a crucial role in determining the price. Established brands with a history of quality and reliability often command higher prices. However, they provide assurances regarding performance and after-sales service.

4. Features and Specifications Advanced features—such as programmable controls, variable speed settings, and integrated dust extraction systems—come with a higher price tag. Buyers should consider what features are necessary for their specific applications to determine the right balance between cost and utility.

5. Market Demand and Location Prices can also fluctuate based on market demand and geographical location. In higher-demand areas or economies, prices may rise due to competition and scarcity. Conversely, in regions where manufacturing is less emphasized, prices might be lower.

buy pipe polishing machine price

The Benefits of Pipe Polishing Machines

Investing in a pipe polishing machine can offer numerous advantages

1. Improved Aesthetic Appeal Polished pipes enhance the visual appeal of products, making them more marketable. A high-quality finish gives the product a premium look that stands out in a competitive market.

2. Enhanced Performance A smooth surface reduces friction, which is crucial in applications where airflow or fluid movement is essential. This is especially important in the automotive and aerospace industries, where efficiency can significantly impact performance.

3. Corrosion Resistance Polishing can remove impurities that may lead to corrosion, thus prolonging the life of pipes. This advantage is particularly critical in industries like oil and gas, where equipment is often exposed to harsh environmental conditions.

4. Time Efficiency Automated and semi-automated machines significantly reduce the time taken for polishing processes. This can lead to higher productivity and reduced labor costs, ultimately benefiting the company's bottom line.

5. Versatility Many pipe polishing machines are designed to work with various pipe sizes and materials, increasing their utility across different projects and industries.

Conclusion

The popularity of pipe polishing machines is on the rise, driven by the need for high-quality, aesthetically pleasing, and durable products. When considering purchasing a pipe polishing machine, it is crucial to evaluate various factors influencing its price, including the type, materials, brand, features, and market conditions. Although the initial investment might seem considerable, the long-term advantages of improved efficiency, performance, and product lifespan make it a worthwhile consideration for any manufacturing operation. Investing in a pipe polishing machine not only enhances operational capabilities but also ensures you remain competitive in a demanding market.