The Importance of Pipe Polishing Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the need for efficiency, quality, and precision is paramount. Among the various machines that facilitate metalworking processes, the pipe polishing machine stands out as an essential tool. This equipment not only improves the aesthetic appeal of pipes but also enhances their durability and performance. In this article, we will explore the significance of pipe polishing machines and why investing in one is crucial for any manufacturing business.

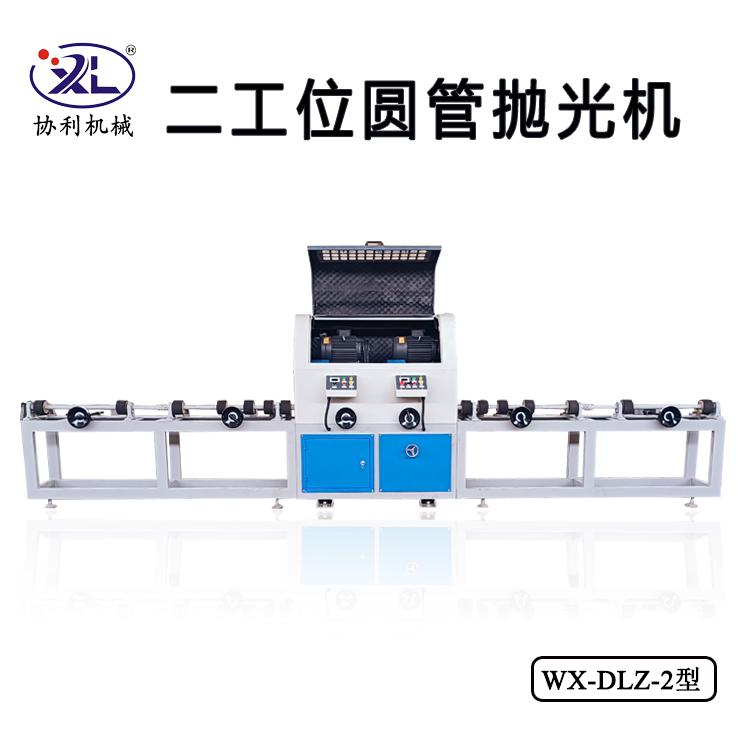

What is a Pipe Polishing Machine?

A pipe polishing machine is a specialized piece of equipment designed to smooth and polish the surface of metal pipes. These machines use an array of polishing techniques, including abrasive belts, brushes, and buffing wheels to achieve a mirror-like finish. The primary goal is to remove imperfections, oxidation, and roughness from the surface, which can significantly affect the pipe's overall performance and appearance.

Benefits of Using a Pipe Polishing Machine

1. Enhanced Aesthetic Appeal Clean and polished pipes are not only visually appealing but also exude professionalism. Industries that require high-quality finishes—such as automotive, aerospace, and architecture—recognize the importance of having visually attractive components. A polished pipe can set a brand apart and attract more clients.

2. Improved Corrosion Resistance One of the major reasons why polishing pipes is critical lies in reducing the likelihood of corrosion. A rough surface can trap dirt and moisture, leading to rust and degradation over time. By using a pipe polishing machine, manufacturers can create a smooth surface that minimizes these risks, thereby extending the lifespan of the pipes.

3. Better Performance In many industrial applications, the performance of pipes is directly linked to their surface finish. A smooth surface allows for improved flow characteristics, reducing friction and minimizing energy loss in systems such as fluid transportation. For example, polished pipes in hydraulic systems can lead to higher efficiency and lower operational costs.

buy pipe polishing machine

4. Time and Cost Efficiency Manual polishing can be labor-intensive and time-consuming. Investing in a pipe polishing machine automates the process, leading to significant time savings. Furthermore, the consistency and quality provided by machine polishing can reduce rework and scrap rates, ultimately saving money in the manufacturing process.

5. Versatility Pipe polishing machines are available in various sizes and configurations, making them suitable for different types of pipes, including stainless steel, aluminum, and brass. This versatility makes them an indispensable asset for manufacturers dealing with diverse materials and products.

Choosing the Right Pipe Polishing Machine

When considering the purchase of a pipe polishing machine, several factors should be taken into account

- Machine Specifications Ensure the machine can accommodate the sizes and materials of pipes you regularly work with. - Automation Features Depending on your production needs, you may want a machine that offers automated features to enhance productivity. - Maintenance Requirements Look for a machine that is easy to maintain, as regular upkeep is essential for ensuring longevity and performance. - Cost vs. Benefit Analyze the potential return on investment. While there may be a significant initial cost, the long-term benefits, including efficiency and quality improvements, often justify the investment.

Conclusion

In summary, a pipe polishing machine is a vital piece of equipment for any manufacturer involved in metal fabrication. The benefits it offers—from aesthetic improvements and corrosion resistance to enhanced performance and cost savings—make it a worthwhile investment. As industries continue to demand higher quality and efficiency, the adoption of advanced machinery like pipe polishing machines will be crucial in staying competitive in the market. If you haven't considered purchasing one yet, now is the time to explore the options available and enhance your manufacturing capabilities.